GE Analytical Instruments, Inc. ©2005H Page 2 of 16 DIN 30001 Rev. E

TOC,FLOW SWITCH UPGRADE 2.12CBI

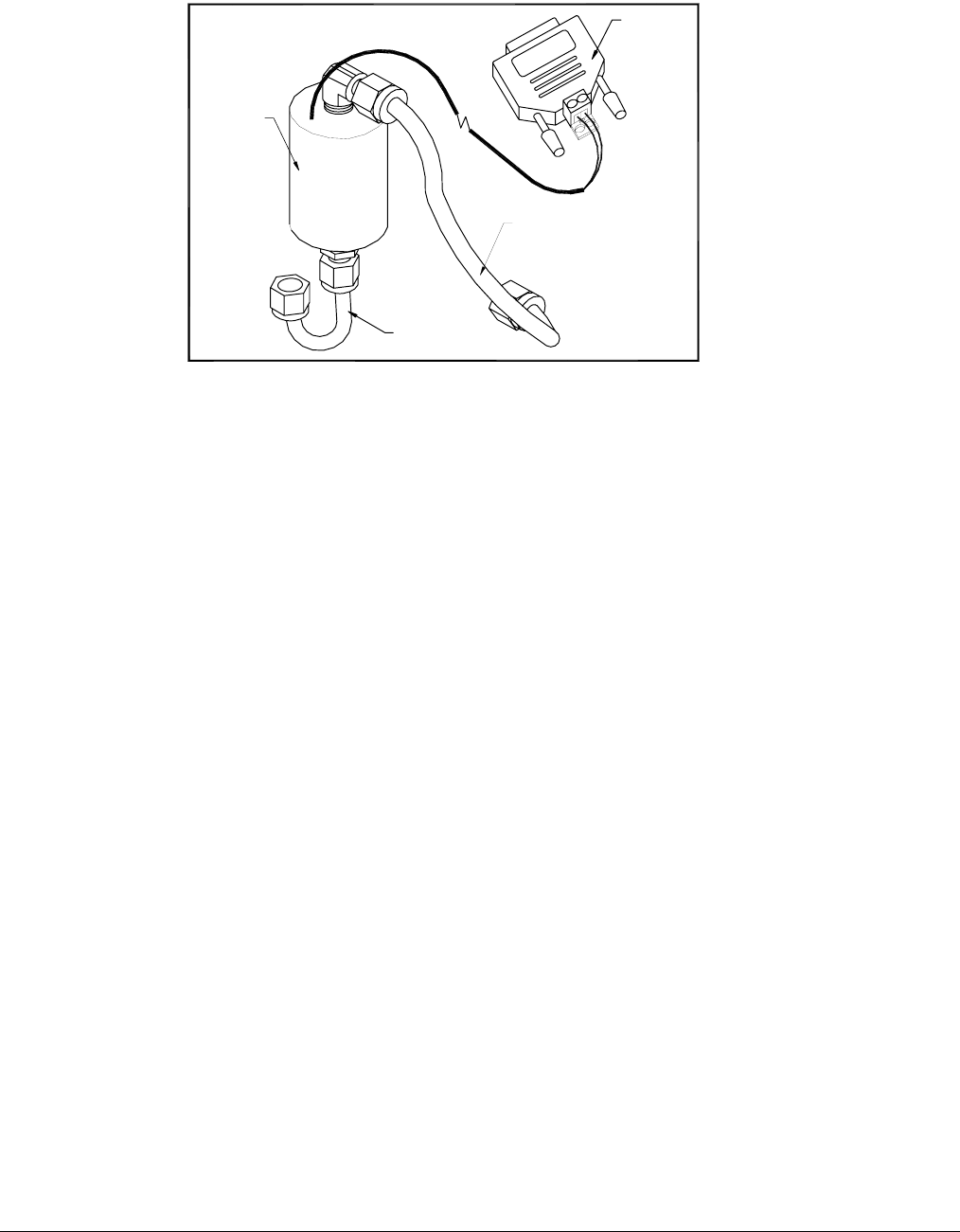

FIGURE ONE: Flow Switch Kit

4. Mechanical installation

Refer to Figures One or Two for this procedure. Reference will depend on orientation

of tubing from regulator.)

4.1. Remove the outlet PFA tube connector from the pressure regulator of the analyzer.

4.2. Detach the regulator from the analyzer by removing the two screws on the bottom of

the mounting bracket making sure not to lose the fiber spacers.

4.3. Remove the elbow from the outlet side of the regulator and clean the port and

connector threads of any Teflon

®

tape remains. Reapply 4 wraps of Teflon tape to

the elbow and screw the fitting back into the regulator ending with the tube fitting

pointing down as shown.

4.4. Reinstall the regulator to the analyzer with the two screws making sure to use the

fiber spacers.

4.5. Remove the PFA tube from the inlet of the sampling block.

4.6. Position the flow switch and secure the end of the stainless steel U-tube to the

regulator outlet. Wires must point up to have a calibrated normally open switch.

4.7. Secure the PFA tube from the outlet of the switch to the inlet of the sampling block.

4.8. Connect the wires from the flow switch to the Binary Input Module, polarity not

important to the binary module.

4.9. Route the electrical cable as desired and plug the end into the AUX PORT on the

opposite side of the instrument.

4.10. If installing the switch on a TURBO analyzer, proceed to 6, if not proceed to 5.

FLOW

SWITCH

STAINLESS

STEEL

TUBING

PFA

TUBING

BINARY

INPUT

MODULE