5

INSTALLATION RECORDS

To keep an accurate record of your installation, be

sure to fi ll out the data below:

ELECTRICAL INSTALLATION

WARNING

Hazardous

voltage can shock, burn or

cause death.

CAUTION

If you are

not sure of proper electrical

connections, consult a licensed

electrician.

CAUTION

Improper wiring

can result in permanent damage

to the motor. All electrical wiring

should meet the local electrical

code.

NOTICE

READ AND FOLLOW ALL INSTRUCTIONS!

• Pump connection must comply with National

Electric Code (NEC) or Canadian Electric Code

(CEC), and all applicable local codes.

• All dual voltage units come factory preset for

230 volts. (Figure 3)

• Disconnect power at electrical panel before

making any electrical connections.

• Supply voltage must be +/- 10% of motor

nameplate voltage. Low or high voltage can

damage the motor and will void the warranty.

• If possible, connect pump to dedicated branch

circuit with no other appliances on it.

• Do not operate pump unless pump is grounded

WARNING

Date of Installation:

Model No.

Depth of Well (ft):

Depth to Water (ft):

Inside diameter of Well:

Suction Pipe Size:

Suction pipe length (ft):

Discharge pipe length (ft):

Motor:

HP:

Volts:

Wire gauge size:

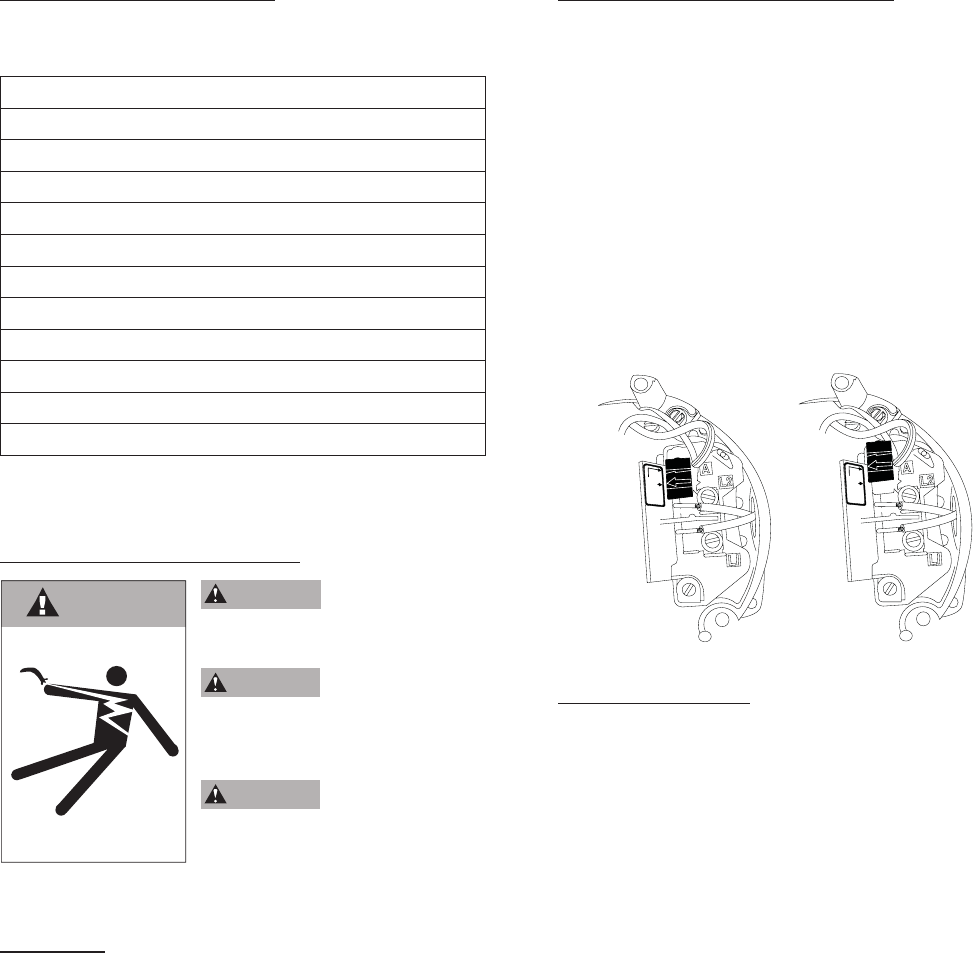

DUAL VOLTAGE ADJUSTMENT

NOTE:

To change the motor voltage(Figure 6) unplug

the dual voltage connector on the motor and reconnect

it in the position required to match the available

electrical system. The motor can be set for 115 volts

or 230 volts, except for 2 hp modles which are 230

volts only. The voltage setting of the motor can be

determined by looking at the alignment of the arrow

on the plug and the arrow on the motor terminal board

(located under the motor’s end cover). Any questions

as to which voltage setting is required for proper motor

and pump operation in your system should be directed

to an electrical professional. The factory preset is

230 volts.

Wiring Installation

NOTICE: Check motor terminal cover or nameplate

for wiring instructions. The essential pump motor facts

are as follows:

1.) 3450 RPM

2.) Single Phase

3.) Dual Voltage, 115/230 on 1 and 1-1/2 HP; 230 V

only on 2 HP motors.

4.) 1/2, 3/4, 1, and 1-1/2 Horsepower motors are

wired for 230 volts as a factory standard.

Step 1:

Remove motor access cover at back of motor.

Step 2:

Feed the grounding wire (green or bare copper)

through the electrical conduit port in the side of the

motor. First connect the ground wire then connect

the power supply wires. Attach the grounding wire

to the motor ground screw (green). Secure wires to

prevent electrical shorts.

230V

115V

230V

115V

115V 230V

Figure 6