30318 R4 9/9/2005

5

through a refrigeration unit unless the

unit is specifically approved for such

service.

Generally, a six-inch clearance between

the air conditioning evaporator coil and

the heat exchanger will provide adequate

airflow through the evaporator coil.

The blower speed must be checked and

adjusted to compensate for the pressure

drop caused by the evaporator coil.

Refer to Appendix B for recommended

wiring and electrical connections of the

air conditioning controls.

COMBUSTION AIR

When a furnace is installed in the full

basement of a typical frame or brick

house, infiltration is normally adequate to

provide air for combustion and draft

operation. If the furnace is installed in a

closet or utility room, two (2) ventilation

openings must be provided connecting to

a well ventilated space (full basement,

living room or other room opening

thereto, but not a bedroom or bathroom).

One opening shall be located 6" from the

top and bottom of the enclosure at the

front of the furnace. For furnaces located

in buildings of unusually tight

construction, such as those with high

quality weather stripping, caulking,

windows and doors, or storm sashed

windows, or where basement windows

are well sealed, a permanent opening

communicating with a well ventilated

attic or with the outdoors shall be

provided, using a duct if necessary. Size

all of the openings and associated

ductwork by the standards provided in

the latest Oil Installation Code editions;

NFPA 31 in the United States, CAN/CSA

B139 in Canada. Take all fuel burning

appliances in the area into consideration

when calculating combustion and

ventilation air requirements.

The Model CAS-2B-90E Furnace Boot

manufactured by Field Controls, Inc. may

be used with the furnace to obtain

combustion air from outdoors. Use of this

device does not alter the need for

ventilation air; however, it does provide a

good source of combustion air and is

connected to the oil burner.

CHIMNEY VENTING

The chimney must be sized correctly and

be in good repair. If the chimney is

oversized, there is a high risk of the flue

gases condensing resulting in damage to

the chimney and other venting parts.

This problem may be corrected by the

use of an appropriately sized chimney

liner.

If the chimney serves the WML-C

furnace only, the vent should be sized at

5-inch minimum. The MPL-B should be

6-inch minimum. The data provided in

Table 3 is based on dedicated venting. If

the furnace is to be co-vented with other

appliances, refer to NFPA 211, Standard

for Chimneys, Fireplaces, Vents, and

Solid Fuel-Burning Appliances, NFPA

31, Standard for the Installation of Oil

Burning Equipment or CAN/CSA B139,

Installation Code For Oil Burning

Equipment for correct sizing information.

NOTE: This furnace is approved for

use with L-Vent.

NOTE: Maximum temperature for L-

Vent is 575°F (300°C).

IMPORTANT: The chimney must be

capable of providing sufficient draft at all

times for the safe removal of the

products of combustion.

The chimney should be tested under

“winter” conditions; doors and windows

closed, all other fossil fuel burning

appliances on, clothes dryer on,

bathroom fans on, etc. If the chimney

cannot overcome the competition for air,

it will be necessary to access the reason

for it, and take corrective action. If the

chimney is found to be sized correctly

and in good repair, it will probably be

necessary to re-evaluate the availability

of combustion and ventilation air, and

take corrective action.

The flue pipe should be as short as

possible with horizontal pipes sloping

upward toward the chimney at a rate of

one-quarter inch to the foot. The flue

pipe should not be smaller in cross

sectional area than the flue collar on the

furnace. The flue pipe should connect to

the chimney such that the flue pipe

extends into, and terminates flush with

the inside surface of the chimney liner.

Seal the joint between the pipe and the

lining. The chimney outlet should be at

least two feet above the highest point of

a peaked roof. All unused chimney

openings should be closed. Chimneys

must conform to local, provincial or state

codes, or in the absence of local

regulations, to the requirements of the

National Building Code.

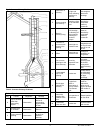

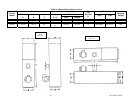

See Figure 2 and Table 2 for common

chimney problems and their remedies.

THE FURNACE MUST BE

CONNECTED TO A FLUE HAVING

SUFFICIENT DRAFT AT ALL TIMES TO

ENSURE SAFE AND PROPER

OPERATION OF THE APPLIANCE.

The flue pipe must not be routed through

concealed space, because it must be

visually checked for signs of

deterioration during the annual

inspection and servicing. The flue pipe

must not pass through any floor or

ceiling, but may pass through a wall

where suitable fire protection provisions

have been installed. In the United States,

refer to the latest edition of NFPA 31 for

regulations governing the installation of

oil burning equipment. In Canada, refer

to the latest edition of CAN/CSA B139

for rules governing the installation of oil

burning equipment.

NOTE: THE RECOMMENDED FLUE

DRAFT PRESSURE IS -0.02 IN. W.C.

(AS MEASURED UPSTREAM OF THE

BAROMETRIC DRAFT REGULATOR).

SHOWN IN FIGURE 1.

DRAFT REGULATOR CONTROL

This device is used in conjunction with

conventional chimney venting. This

control (or draft regulator) automatically

maintains a constant negative pressure

in the furnace to obtain maximum

efficiency. It ensures that proper

pressures are not exceeded. If the

chimney does not develop sufficient

draft, the draft control cannot function

properly. The draft regulator, must be

installed within the same room or

enclosure as the furnace, and should not

interfere with the combustion air supplied

to the burner. The control should be

located a minimum of 3 flue pipe

diameters from the furnace breeching

and installed in accordance to the

instructions supplied with the regulator.