30318 R4 9/9/2005

29

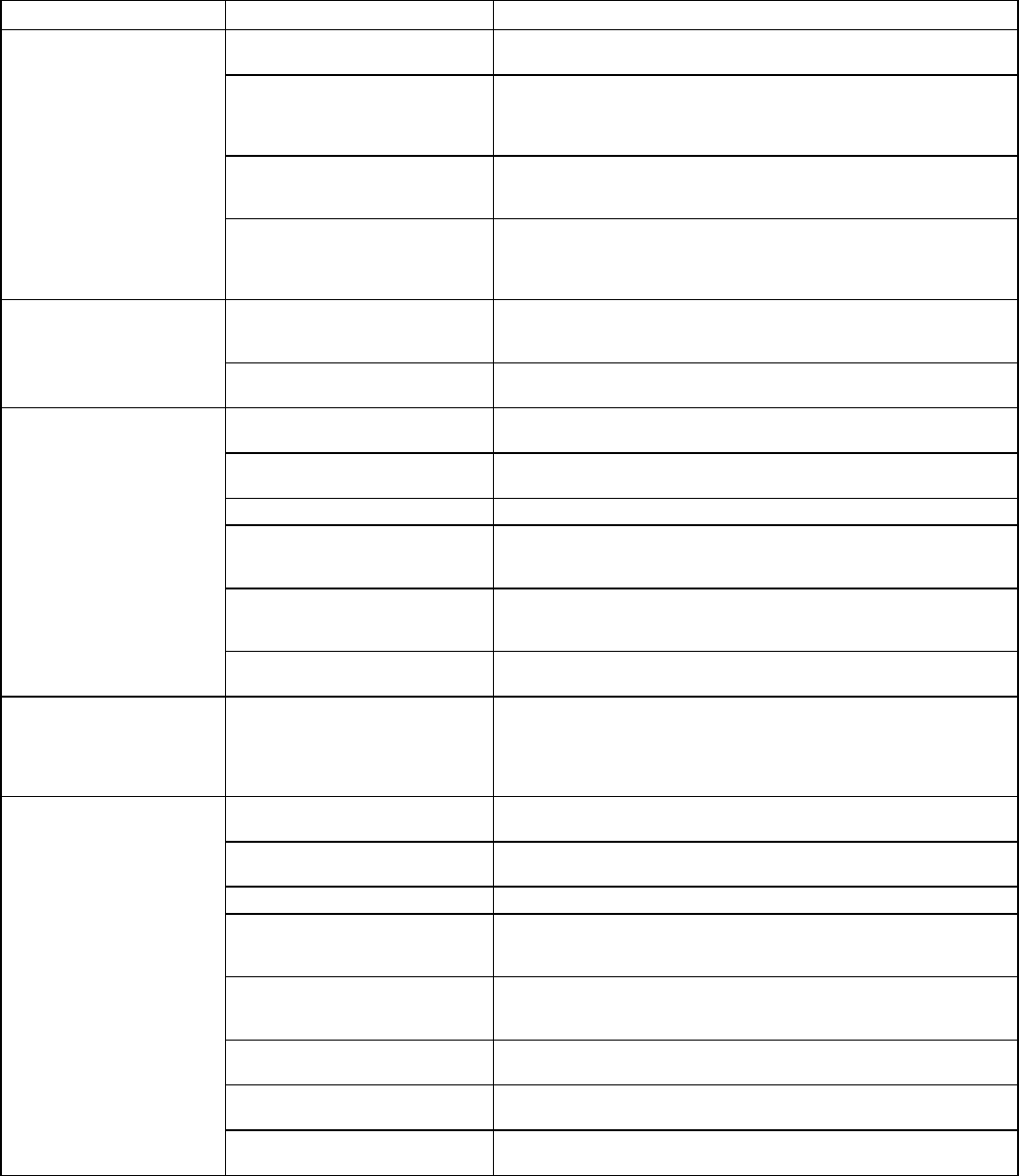

TABLE C4: SYSTEM AND GENERAL TROUBLESHOOTING

Problem Possible Cause Remedy

Thermostat not calling for heat.

Check thermostat and adjust. Also, check thermostat for accuracy; if it is

a mercury switch type, it might be off level.

No power to furnace.

Check furnace switch, main electrical panel furnace fuse or circuit

breaker. Also look for any other hand operated switch, such as an old

poorly located furnace switch, which was not removed during furnace

replacement.

Thermostat faulty.

Remove thermostat wires from oil primary control terminals T-T. Place a

jumper across T-T. If furnace starts, replace thermostat, thermostat sub-

base (if equipped), or both.

Furnace will not start.

Oil primary control faulty.

Check reset button on oil primary control. Remove thermostat wires

from oil primary control terminals T1 - T2. Check for 24v across T -T. If

no voltage is present, check for 115v to oil primary control. If 115v is

present, go to Table C-3.

Photo Cell wiring shorted or room

light leaking into photo cell

compartment

Check photo cell (cad cell) wiring for short circuits. Also, check for room

light leaking into cad cell compartment. Repair light leak if necessary.

See Table C-3.

Furnace will not start.

Open safety switch.

Check for open limit or auxiliary limit. Also, check internal wiring

connections; loose connectors, etc.

No fuel oil.

Check fuel oil supply. Check that all hand operated fuel oil valves are in

the open position. Fill oil storage tank if necessary.

Clogged nozzle.

Replace nozzle with high quality replacement. Use rating plate or Tables

in Appendix A as a guide.

Clogged oil filter. Replace oil tank filter or in-line filter if used.

Low oil pump pressure.

Connect pressure gauge to oil pump. Adjust pump pressure, or replace

oil pump if necessary. Ensure that erratic pressure readings are not

caused by defective fuel oil line.

Air getting into fuel oil lines, or fuel

oil line dirty, clogged, or in some

manner defective.

Check fuel oil lines. Replace any compression fittings found with high

quality flared fittings. Check for any signs of oil leaks. Any oil leak is a

potential source of air or contaminants.

Furnace will not start without

first pushing oil primary

control reset button.

(Happens on frequent basis)

Defective burner motor.

Check burner motor. If burner motor is cutting out on over-load,

determine why. Replace if necessary.

Furnace starts, but cuts out

requiring manually resetting

the oil protector reset button.

Photo Cell (Cad Cell) defective.

If cad cell is dirty, clean it. (Determine why cad cell is getting dirty). If

cad cell is poorly aimed, realign it. NOTE: The photocell should have a

resistance of 100K Ω in absence of light; a maximum of 1500 Ω in the

presence of light. Ensure that room light is not leaking into the cad cell

compartment. (See diagnostic light section).

No fuel oil.

Check fuel oil supply. Check that all hand operated fuel oil valves are in

the open position. Fill oil storage tank if necessary.

Clogged nozzle.

Replace nozzle with high quality replacement. Use rating plate or Tables

in Appendix A as a guide.

Clogged oil filter. Replace oil tank filter or in-line filter if used.

Low oil pump pressure.

Connect pressure gauge to oil pump. Adjust pump pressure, or replace

oil pump if necessary. Ensure that erratic pressure readings are not

caused by defective fuel oil line.

Air getting into fuel oil lines, or fuel

oil line dirty, clogged, or in some

manner defective.

Check fuel oil lines. Replace any compression fittings found with high

quality flared fittings. Check for any signs of oil leaks. Any oil leak is a

potential source of air or contaminants.

Defective burner motor.

Check burner motor. If burner motor is cutting out on over-load,

determine why. Replace if necessary.

Water or contaminants in oil.

Drain fuel oil storage tank, replace fuel oil. (Consult with fuel oil

supplier).

Furnace starts, but cuts out

requiring manually resetting

the oil protector reset button.

Frozen oil line.

Gently warm oil line. Insulate oil line. (Outdoor piping size may require

increased diameter).