30318 R4 9/9/2005

30

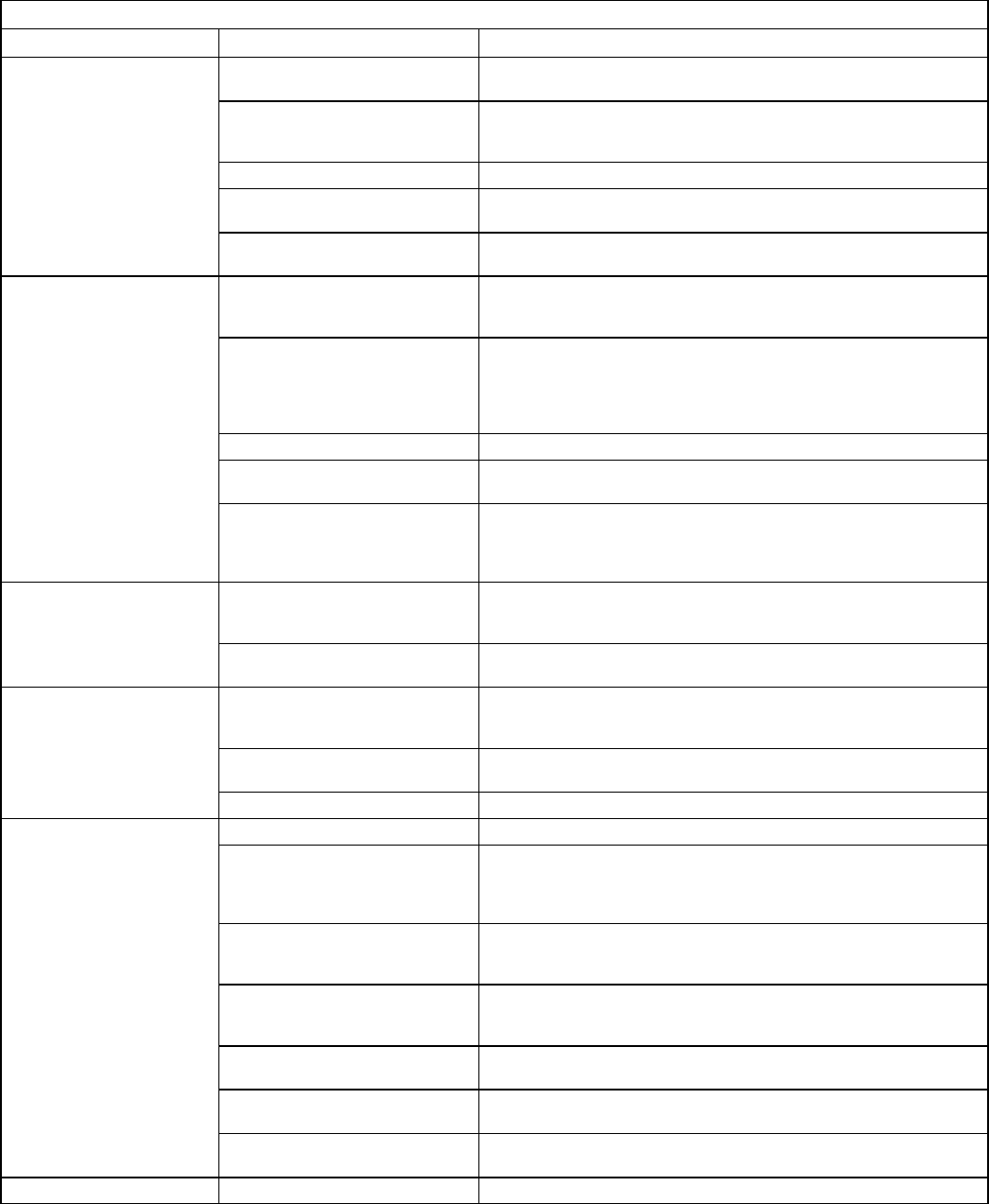

TABLE C-4: SYSTEM AND GENERAL TROUBLESHOOTING continued

Problem Possible Cause Remedy

Electrodes out of adjustment or

defective.

Check electrode settings. Check electrodes for dirt build-up or cracks in

porcelain.

Poor transformer high voltage

connections or defective

transformer.

Check contacts between the igniter and electrodes. If OK, replace the

igniter

Fuel oil filter clogged. Replace fuel oil storage tank filter and / or fuel oil in-line filter.

Defective oil pump.

Check burner motor / fuel oil pump coupling. Check oil pump pressure.

Replace fuel oil pump if necessary.

Oil burner sputtering at

nozzle

Fuel oil line partially clogged or

contains air.

Bleed air from oil line. If problem persists, replace oil line.

System temperature rise too high.

System temperature rise ideally should not exceed 85°F. Check for

clogged air filters. Check blower fan for excess dirt build-up or debris.

Speed up blower fan if necessary.

Poor “fan off” delay timing

selection, (fan stops too soon).

Check “fan off” delay timing setting. Use a duct thermometer in the

supply air plenum take-off or first few inches of the supply air trunk duct.

Ideally, the fan will shut off at a temperature of 90° - 100°F. Manipulate

the dip switch settings to come as close as possible to this “fan off”

temperature.

Fuel oil leak. Check fuel oil line for leaks. Repair or replace if necessary.

Stack temperature too high.

Check stack temperature. Stack temperatures will normally range from

350° to 450°F. Check draft regulator. Draft should be set to 0.02 in. w.c.

Excessive fuel oil

consumption.

Thermostat improperly adjusted or

in poor location.

Check thermostat heat anticipator setting against measured amperage

draw. Increase heat anticipator setting if necessary. If the thermostat is

being influenced by drafts, sunlight, duct work, etc., relocate to more

suitable location.

Insufficient combustion air

adjustment at oil burner, or

improper draft pressure.

Adjust the oil burner combustion air band and draft regulator to gain the

highest practical CO

2

or lowest practical O

2

content in the flue gases.

See Burner Set Up.

Too much smoke.

Heat exchanger partially clogged.

Check for soot build-up in heat exchanger flue passages, especially in

the outer radiator.

Poor alignment between oil burner

blast tube and fire pot.

Check alignment. Blast tube should be centered with fire pot burner

opening. Oil burner head should be ¼ inch back from the inside surface

of the fire pot.

Flame impingement caused by

Incorrect nozzle angle.

Check nozzle size and angle. (See Appendix A). Check distance from

head to inside surface of the fire pot.

Soot building up on blast

tube (end coning).

Defective fire-pot Check fire-pot. Repair or replace.

Airflow blocked or dirty air filter. Clean or replace air filter.

Thermostat adjustments or

location.

Check thermostat heat anticipator setting against measured amperage

draw. Increase heat anticipator setting if necessary. If the thermostat is

being influenced by drafts, sunlight, duct work, etc., relocate to more

suitable location.

Insufficient airflow.

Check all dampers. Open closed dampers including registers in unused

rooms. Check system temperature rise. If temperature rise is too high,

speed up blower fan.

Defective high limit control.

Test high limit function of all limit switches. Use a duct thermometer to

assess accuracy of limit control. Check for obstructions to airflow around

limit switch bi-metal elements. Replace control if necessary.

Under-sized nozzle.

Check nozzle. If problem is not caused by air flow problems, use larger

nozzle, if permitted by rating plate.

Blower fan motor stopping

intermittently on overload.

Check blower fan motor amperage draw. Check motor ventilation ports,

clean if necessary. Replace motor if necessary.

Furnace will not warm home

to desired temperature.

Burner motor stopping

intermittently on overload.

Check burner motor. Replace if necessary.

Home does not heat evenly Improper distribution of heat. This is not likely to be a furnace problem. Balance duct system.