30318 R4 9/9/2005

4

HORIZONTAL INSTALLATION

WML-C AND MPL-B furnaces models

are assembled and shipped ready for

installation in the down-flow position. The

furnace may be installed in either of the

horizontal positions; warm air

discharging left or warm air-discharging

right by following these steps:

1. Rotate the furnace 90° to the

desired position.

2. Remove the three nut and washer

sets fastening the oil burner

assembly to the furnace. Rotate the

oil burner assembly to be in the

normal upright position.

3. Re-align the oil burner assembly to

the combustion chamber (fire-pot),

and then secure into place with the

three nut and washer sets.

NON-SUSPENDED INSTALLATION

Maintain clearances to combustibles as

outlined in Table 1. Installation on a

combustible floor requires a clearance of

1 inch. This can be done by using a

noncombustible material such as one-

inch thick channel iron or similar

material. The furnace must be supported

in such a way as to not allow twisting or

sagging of the cabinet. Suggestion; as a

measure to prevent fuel oil from

accumulating in locations other than the

fire pot, as could be the case in the event

of nozzle drip, install the furnace with an

approximate 2-degree slope from the oil

burner casing towards the fire pot. Use

shims made of noncombustible material.

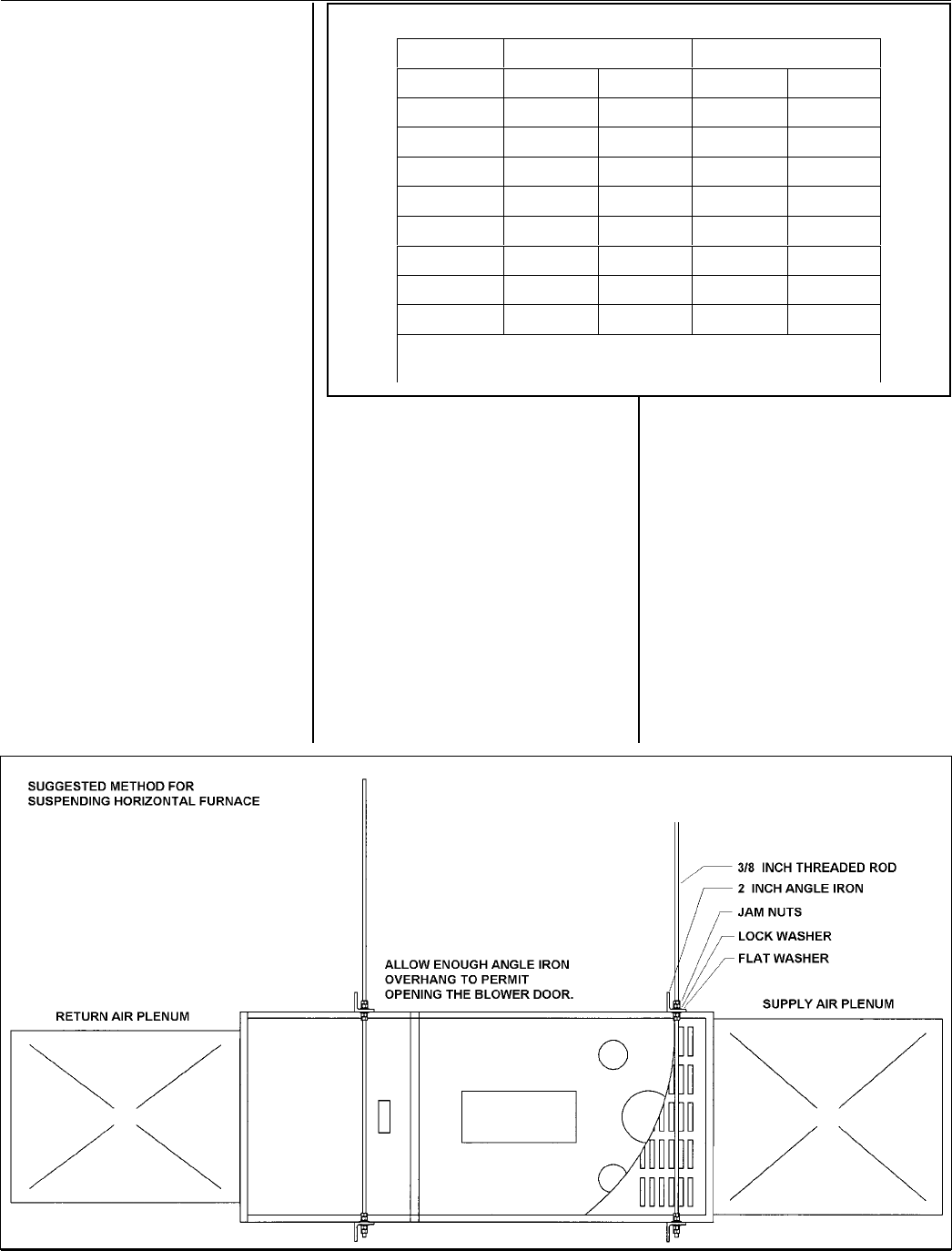

SUSPENDED INSTALLATION

Refer to Figure 1. Maintain clearances to

combustibles as outlined in Table 1. The

furnace may be suspended by field

fabricating a cradle of angle iron and

threaded rod. Secure the furnace with 2

inch minimum slotted angle or

equivalent, as shown in Figure 1. The

furnace must be supported in such a way

as to not allow twisting or sagging of the

cabinet. Position the supports so as to

not interfere with accessing the burner

and blower compartments. Suggestion;

as a measure to prevent fuel oil from

accumulating in locations other than the

fire pot, as could be the case in the event

of nozzle drip, install the furnace with an

approximate 2 degree slope from the oil

burner casing towards the fire pot.

AIR CONDITIONING

If the furnace is used in conjunction with

air conditioning, the furnace shall be

installed in parallel with or upstream from

the evaporator coil to avoid condensation

in the heat exchanger. In a parallel

installation, the dampers or air controlling

means must prevent chilled air from

entering the furnace. If the dampers are

manually operated, there must be a

means of control to prevent the operation

of either system unless the dampers are

in the full heat or full cool position. The

air heated by the furnace shall not pass

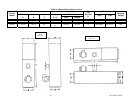

Table 1: Clearance to Combustibles

Furnace

WML-C MPL-B

Location Down flow Horizontal Down flow Horizontal

Top 0 in. 3 in. 0 in. 3 in.

Bottom 1 in. 1 in. 1 in. 1 in.

S/A Plenum 1 in. 1 in. 1 in. 1 in.

Rear 1 in. 1 in. 1 in. 1 in.

Sides 1 in. 1 in. 1 in. 1 in.

Front 10 in.

1

10 in.

1

10 in.

1

10 in.

1

Flue Pipe 9 in.

2

9 in.

2

9 in.

2

9 in.

2

Enclosure Closet Closet Closet Closet

1

24 inches is required for servicing.

2

18 inches required in the United States.

Fig 1 Suspended Installation