1

MODEL F80A

F

URNACE COMPONENTS

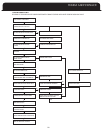

Figure 1 (below) is provided to help identify the

c

omponents of your furnace.

REGULATOR VENT

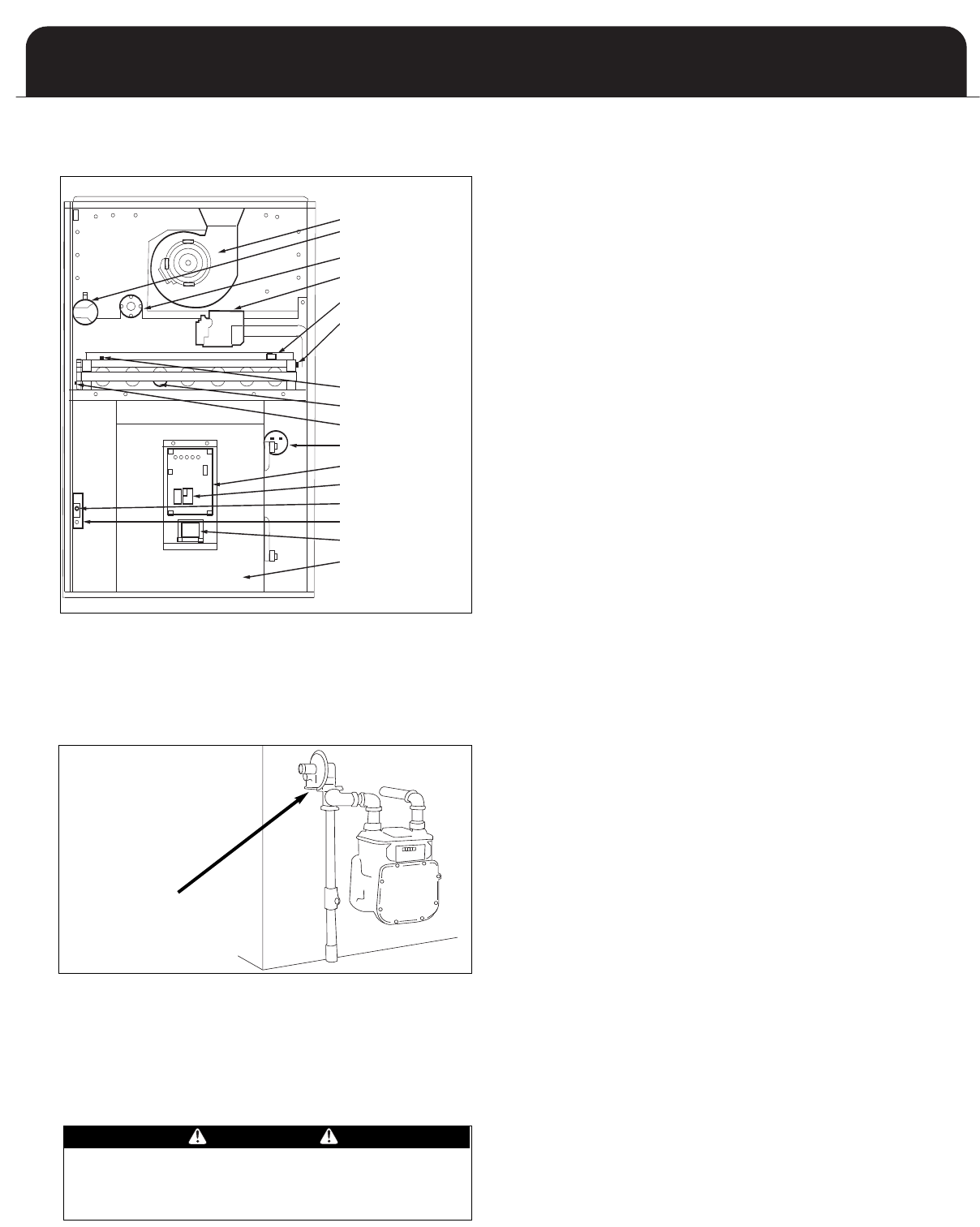

Most natural gas systems and all LP gas systems have a

service regulator located near the point where the gas

piping enters the building. The propane tank will normally

have an additional first stage regulator located at the tank

outlet valve. All of these regulators (located outdoors) will

have a vent; see Fig. 2 (below).

It is important for these vents to remain clear. Do not allow

moisture, which could freeze, to build up in the vent. If you

see moisture building up in the regulator vent, contact your

gas supplier.

Your gas supplier should periodically inspect and clean the

air vent screen to prevent any obstruction. Keep the

protective regulator cover in place, as exposure to the

elements can cause ice buildup and a regulator failure.

WARNING

AN OBSTRUCED AIR VENT ON AN LP (PROPANE)

CYLINDER OR TANK REGULATOR CAN CAUSE EXPLOSION

OR FIRE RESUL

TING IN PROPER

TY DAMAGE, SEVERE

PERSONAL INJURY OR DEATH.

Regulator vent

Keep free of ice, snow

,

and debris

Figure 1: Furnace Components

Figure 2:

Gas Regulator Vent

Induced Blower

Pressure Switch

L

imit Switch

Gas Valve

Igniter

Rollout Switch

Flame Sensor

Burners

Rollout Switch

Motor Capacitor

Control Panel

Furnace control

Door Switch

Junction Box

Transformer

Blower

GENERAL SAFETY RULES

1. Combustible materials should not be stored against or

around the furnace. Keep the furnace area clear and

free from all combustible materials such as newspapers,

r

ags, cardboard, clothing, etc. This applies especially to

gasoline and other flammable vapors and liquids.

2. A furnace needs adequate amounts of combustion and

v

entilation air to operate properly. Do not block or

obstruct air openings on the furnace, or air openings

supplying combustion or ventilation air to the area

w

here the furnace is installed. There are many areas

from which your furnace could be receiving combustion

and ventilation air including from within the heated

area (inside air), from outdoors, from an attic or crawl

space. If renovations are done, be sure that air supply

openings are not inadvertently covered over with

insulation, vapor barrier, or similar construction

material.

3. All doors and panels must be in place during normal

furnace operation. Attempting to operate the furnace

with missing doors or panels could lead to the creation

of carbon monoxide gas.

4. If the furnace is installed in a confined space or if you

intend to build a furnace room where insulation is

present, be aware that some insulating materials are

combustible. Do not allow building insulating materials

to come into contact with the furnace.

5. Any additions, alterations or conversions required in

order for the furnace to properly match the application

requirements must be done by a qualified installation

contractor, service agency or gas supplier, using factory

specified or approved parts.

6. Familiarize yourself with the location of the furnace gas

manual shutoff valve and any electrical switches, fuse or

circuit breaker associated with the furnace.

7. For your protection, the furnace is equipped with

manually reset flame rollout switches. If either switch

trips frequently, do not ignore this, call your installation

contractor, service agency or gas supplier.

8. Should the gas supply fail to shut off or if overheating

occurs, shut off the gas valve to the furnace before

shutting off the electrical supply.

9. Familiarize yourself with the location of your furnace

filter or filters. A blocked air filter will reduce efficiency,

increase fuel consumption, raise the furnace operating

temperature, and shorten the life of furnace

components.

10. Do not cover return air grilles and supply air registers

with drapes, curtains, throw rugs, etc.

11. Avoid shutting off supply air registers in the interests of

saving heat. The furnace requires a sufficient quantity

of air passing over the heat exchanger to operate

within design temperatures, (system temperature rise).

Reducing the availability of supply air registers may

have the unforeseen consequence of raising the

furnace operating temperature above design, thereby

reducing furnace ef

ficiency

, and shortening the life of

the furnace components.