15

MODEL F80A

S

ETTING THE MANIFOLD (Outlet) GAS PRESSURE

(F92-1003 36G Valve Pressure Check Kit)

1. Shut off the gas upstream of valve and move valve

switch to “OFF”.

2. Using the 3/32 inch hex wrench that is included in the

v

alve pressure check kit, rotate outlet pressure tap

s

crew one revolution counter-clockwise.

3

. Attach the 5/16 inch hose that is included in the valve

pressure check kit to the outlet pressure boss of the

valve. Hose should overlap boss 3/8 inch.

4. Connect 5/16 inch side of connector that is included in

the valve pressure check kit to the hose on outlet boss.

C

onnect 1/4 inch side of connector to manometer hose.

5. Turn on gas supply to valve and move valve switch to

the “ON” position.

6. Turn on furnace following manufacturer’s instructions.

7. Using a leak detection solution check for leaks at hose

connections.

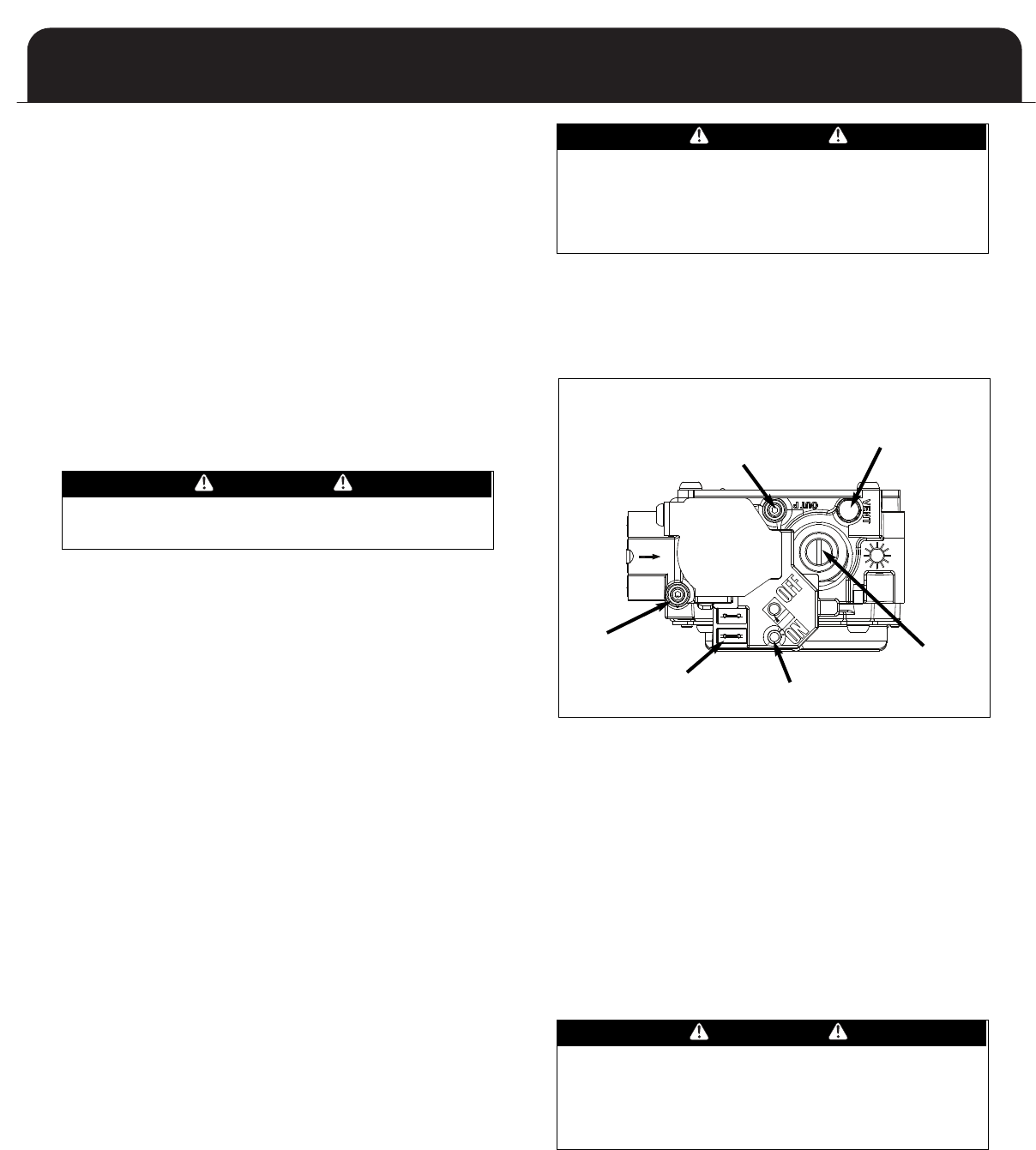

Figure 8: White-Rodgers Gas valve

DANGER

A

TRAINED, QUALIFIED TECHNICIAN MUST DO ALL

REGULATOR ADJUSTMENTS. IMPROPER MODIFICATIONS

OR ADJUSTMENTS CAN RESULT IN FIRE OR EXPLOSION

CAUSING PROPERTY DAMAGE, SEVERE PERSONAL

INJURY OR LOSS OF LIFE.

In some circumstances, high inlet pressure can be remedied

with the use of an inline appliance regulator. If an inline

appliance regulator is used, ensure that it has the capacity

t

o adequately handle the gas volume required by the

furnace and any other appliances receiving gas from the

header serving the furnace.

ELECTRICAL SPECIFICATIONS

Before proceeding with the electrical connections, ensure

that the available electrical supply is compatible with the

voltage, frequency, and phase listed on the appliance rating

plate.

All furnaces are rated 120 VAC, 60 Hz, 1 phase. The

amperage rating is indicated on the furnace rating plate.

Each furnace requires a dedicated overcurrent device either

a circuit breaker or a Type D, time delay fuse. It is

permissible to connect furnace accessories such as

humidifier transformers, condensate pumps and electronic

air cleaners. If adding accessory equipment to the furnace

circuit, ensure that the combined amperages listed on the

appliance rating plates do not exceed the rating of the over

current device.

DANGER

SHUT OFF ELECTRICAL POWER AT THE FUSE BOX OR

SERVICE PANEL BEFORE MAKING ANY ELECTRICAL

CONNECTIONS. FAILURE TO DO SO CAN CAUSE

ELECTRICAL SHOCK RESUL

TING IN PERSONAL INJUR

Y OR

LOSS OF LIFE.

DANGER

SHUT OFF GAS AND FIX LEAKS IMMEDIATELY BEFORE

PROCEEDING.

Outlet

Pressure

Boss

Inlet

Pressure

Boss

(Optional)

Regulator

Vent

On/Off Switch

Regulator

Adjustment

Connection

Terminals

8. Read manometer. This reading is the system

outlet/supply pressure.

9. Follow manufacturer’s instructions to adjust outlet

/supply pressure, if necessary.

10. Shut off gas supply upstream of valve and move the

valve switch to the “OFF” position.

11. Remove manometer and hose from outlet boss.

12. Turn outlet pressure tap screw clockwise to seal the

pressure point using the supplied hex wrench. Tighten

to 13 in-lbs. minimum.

13. Turn on gas supply to valve and move valve switch to

the “ON” position.

14. Turn on furnace following manufacturer’s instructions.

15. Using leak detection solution check for leaks at outlet

pressure tap. Shut off gas and fix all leaks immediately

before proceeding.

If problems were encountered with obtaining enough

pressure on the manifold, first examine the gas piping

system to ensure that it is correctly sized. Pipe sizing is

specified in ANSI Z223.1 / NFPA 54 in the U.S., or the B148

Natural Gas and Propane Installation Code in Canada.

CHECKING THE SUPPLY (Inlet) GAS PRESSURE (F92-1003

Valve Pressure Check Kit)

Check inlet pressure following steps 1 through 15 above

using the inlet/supply pressure tap boss.