18

WARM AIR FURNACE

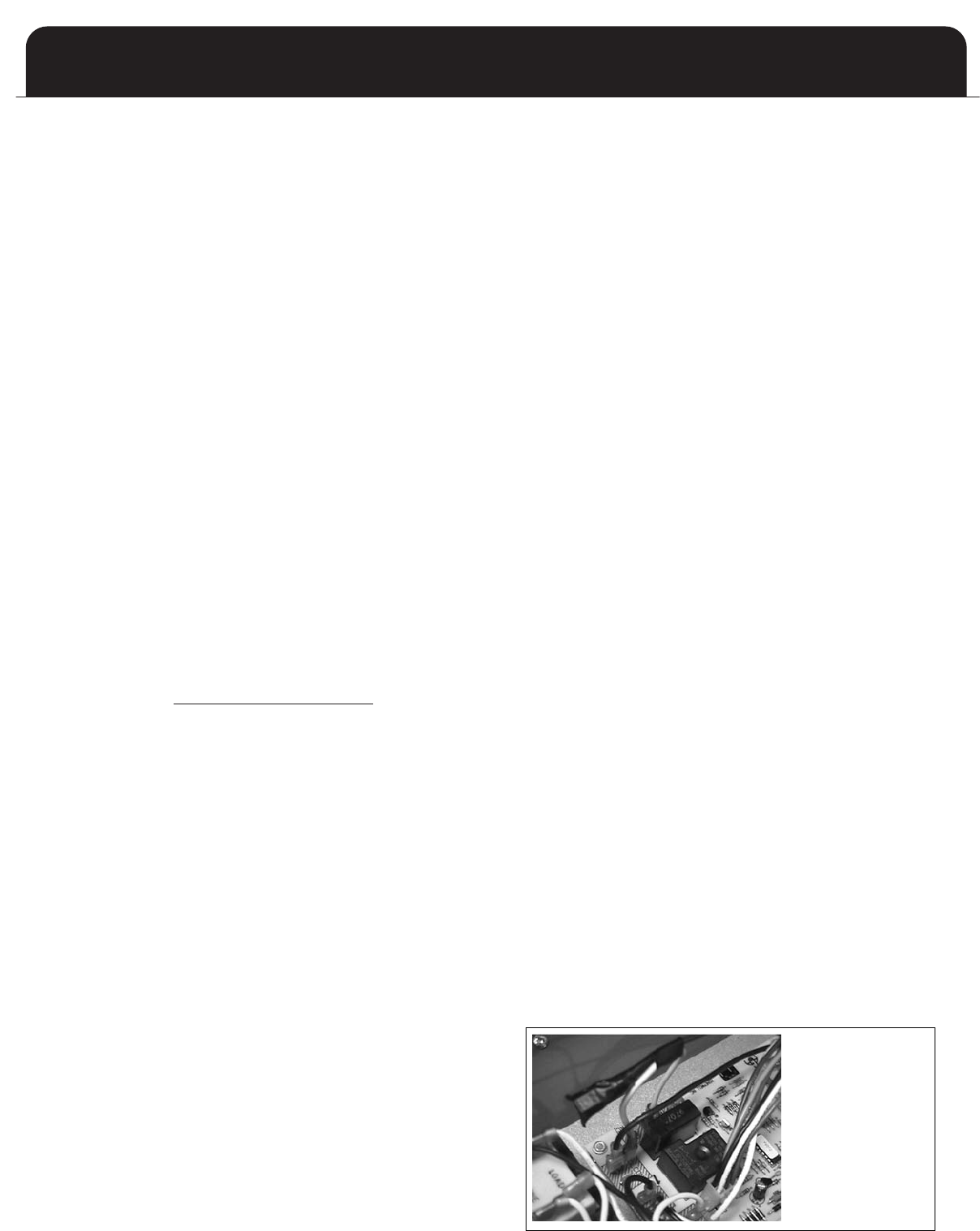

Figure 10:

Piggyback

Connector

Remove blue wire

from HEA

T terminal,

tape it off, and

replace it with a

jumper. Connect the

black wire and

jumper to COOL.

C

HECKING FURNACE INPUT

•

The natural gas supply pressure should be a maximum of

7 inches w.c. and minimum of 5 inches w.c.

•

The burner manifold pressure is normally set to 3.5 inches

w.c. for natural gas

• The input rating of the furnace is based on 1075 / BTU/cu.

f

t. gas with a specific gravity of 0.60

Since heating values for the gas vary geographically, the

a

ctual furnace input and output will vary accordingly.

For example, natural gas with a 1000 BTU / cu. ft. heating

v

alue will reduce the input to 93% of the rated input.

Natural gas with a 1100 BTU / cu. ft. heating value will

increase the input to approximately 103% of the rated

input. This is not usually a problem; however, adjustments

to compensate for this can be made by minor adjustments

to the burner manifold pressure or by changing the burner

orifice size.

In the previous example where the heating value of the gas

is 1100 BTU / cu. ft., the burner manifold pressure can be

reduced .3% to 3.4% w.c. which is within the ±0.30 inches

w.c. specification to bring the input into compliance. Refer

also to Setting the Gas Pressure, and contact the fuel

supplier for specific gas heating content values.

If using a gas meter to check the furnace input, be sure that

all gas fired appliances other than the furnace are off

during the test.

Any adjustments to the burner manifold pressure should be

carried out with the use of a manometer or calibrated

magnehelic gauge. Do not adjust the gas valve pressure

regulator more than ± 0.30 inches water column.

The formula for determining the furnace input via the gas

meter test dial is:

Where:

Input is expressed in BTU / Hr.

Heating value of the gas is expressed in BTU / cubic feet

Time means time required for the test dial to indicate 1

cubic foot in seconds.

If using a gas meter with SI (metric) units:

1 cubic foot = 0.0283 cubic meters.

1 cubic meter = 35.315 cubic foot.

0.01cubic meter = 0.3531 cubic foot.

0.5 cubic meter = 1.766 cubic feet.

Input

Heating Value of Gas 3600

Time in Sec. for 1 cu. ft

=

X

VALUES

H VALUE OF NATURAL GAS in BTU / FT_

1000 1050 1100

46,512 48,837 51,163

65,116 68,372 71,628

125,581 131,860 138,140

T

EMPERATURE RISE CHECK

When the duct system is complete and the air filter or filters

are in place, determine if the airflow is correct.

1. Insert a duct thermometer in the supply air duct. The

thermometer should be placed as close as practical to

t

he furnace, but out of the "line of sight" of the heat

exchanger (this prevents false readings owing to

radiant heat). Ensure that the thermometer location is

within the duct air stream. Avoid locations such as the

inside radius of an elbow, etc.

2. Insert a duct thermometer in the return air duct as

close to the furnace as practical. Ensure that the

t

hermometer location will be unaffected by humidifier

bypass ducts, etc. Choose a location well within the

main air stream.

3. Operate the furnace long enough to obtain steady

state conditions.

4. When the two thermometers have stabilized, usually

within 5 - 8 minutes, compare the two readings.

Subtract the return air temperature from the supply air

temperature. The difference is the temperature rise,

also called

∆T.

5. Compare the measured

∆T to the temperature rise

range shown on the rating plate.

Unless stated differently on the rating plate, the

temperature rise should normally range between 30° to

60°F or 35° to 65°F. When adjusting the temperature rise,

the ideal temperature is approximately mid-range.

If the measured

∆T is above the approved temperature

range, there is too little airflow. The airflow must be

increased by selecting a faster fan speed, removing

restrictions in the ductwork, or adding supply or return

ductwork.

If the measured

∆T is too low, there is too much airflow.

Use a lower speed tap on the multispeed motor. The blow-

er speed is changed at the integrated furnace control.

Remove the wire from the “HEAT-H” terminal of the

50A55-20 integrated furnace control and plug in the

desired wire on the “HEAT-H” terminal. When this config-

uration is used, the following color codes are used: Black -

High Speed, Blue - Medium-High Speed, Yellow - Medium-

Low Speed and Red - Low Speed. The unused leads are

connected to the M1, M2 terminals on the 50A55-20 inte-

grated furnace control.

IMPORTANT: If the heating speed and cooling speed are to

be the same, remove the cooling lead from the control,

tape it of

f, then install a "piggyback" connector from the

control "HEAT" terminal to the "COOL" terminal. UNDER

NO CIRCUMSTANCE MAY TWO MOTOR WINDINGS BE

POWERED SIMUL

T

ANEOUSL

Y

.

The piggyback connector is used for both types of motor

wiring configuration wiring block and permanent lead, see

figure 10 below.

IMPORTANT: NEVER ADJUST THE INPUT OF THE FURNACE

TO EXCEED THE INPUT SHOWN ON THE RATING PLATE.