www.enviromaster.com

21

Multi-zone Heat Pump Condensing Units

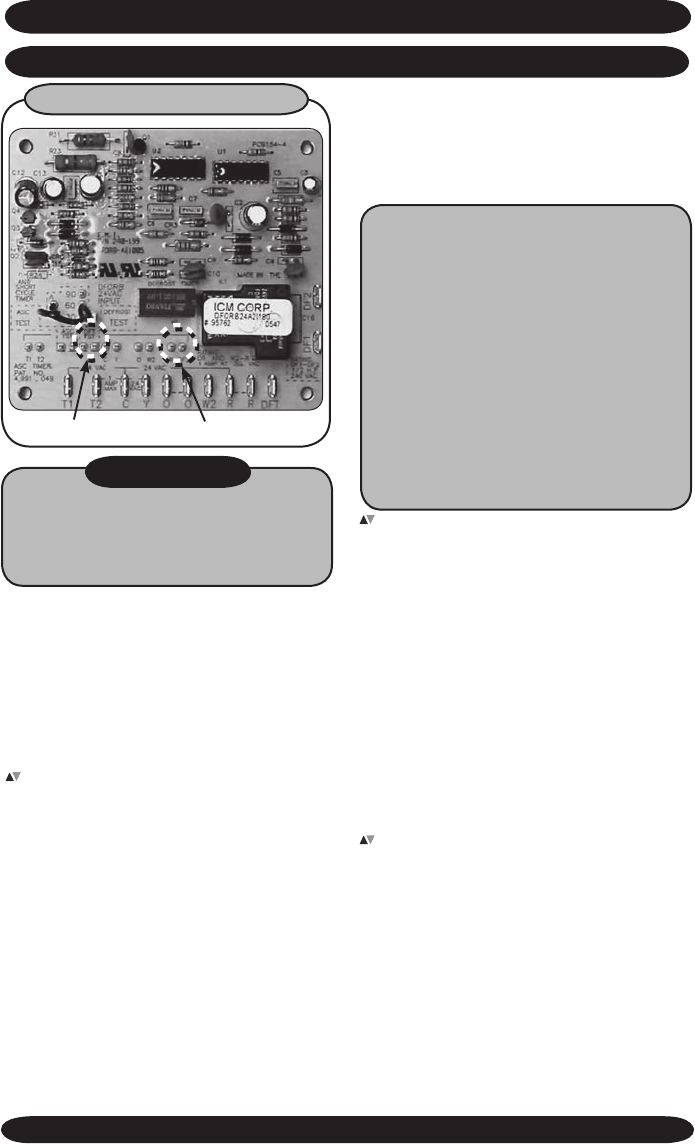

DFT TST R and DF2

DEFROST CONTROL

TESTING DEFROST OPERATION USING TEST PINS

SINGLE-ZONE AND DUAL-ZONE SEQUENCE OF OPERATION

WARNING!

Before removing the access panels to

the unit make sure that all power is dis-

connected from the unit. Failure to do so

could result in injury or electric shock.

Defrost operation can be initiated us-

ing the test pins located on the circuit

board of the condensing unit. “Defrost test

operation” will be a time compressed ver-

sion of the actual defrost cycle.

With the system “off”, using two small

alligator clips, jumper the following sets of

test pins. “R and DF2” and “DFT TST”.

Defrost control board: Apply power

to the indoor and outdoor units. Place the

indoor unit in heating mode with the set

point temperature well above room tem-

perature. This is to ensure that the con-

denser will remain on during the entire

defrost test operation.

The condenser will operate in heat-

ing for approximately 20 seconds. At that

point the unit will enter defrost mode for

approximately 2 seconds. During this time

the condenser fan will switch off, the re-

versing valve will energize and the defrost

board will energize the indoor electric

heat relay through the “W” terminal. After

the two second defrost cycle is complete,

the unit will switch back to heating opera-

tion for another 20 seconds. This process

will repeat until the jumpers are removed

from the test pins.

Note: If the condenser coil is heavily

frosted up with ice, it is likely that the

“Defrost Sensor” is already closed. In

this case the “R and DFT” jumper can

be eliminated. To initiate defrost, mo-

mentarily jump pins marked “DFT TST”

until the defrost cycle begins. The unit

will remain in defrost mode until the

condenser coil is defrosted and then it

will return to heating mode. When test-

ing is complete be sure to remove the

jumper(s). DO NOT leave the unit in

test mode with jumper(s) in place.

Defrost controls with short cycle

protection (heat pumps only): The unit

is equipped with a logic control circuit de-

signed to keep system operating at peek

efciency. The 24V circuit provides control

to the indoor and outdoor systems includ-

ing a three minute, anti-short cycle timer

(ASCT) compressor protection.

The defrost control circuit is designed

to keep the condenser coil free from frost

and ice during heating mode. This is ac-

complished through the precise switching

sequence of the outdoor fan, reversing

valve and indoor auxiliary heater.

Defrost initiation: The defrost-sensor

is located on either the end plate or the re-

turn bend of the condenser coil. A defrost

cycle will initiate after the sensor closes

(approx. 30° F) and remains closed for

the length of time selected on the control

board (either 30, 60 or 90 minutes)*.

At the start of the defrost cycle, the re-

versing valve will change from heating to

cooling mode. The condenser fan will also

switch off, there-by allowing pressure and

temperature to rise within the condenser