6

i

INDICATION - If a Ground Fault Interrupt protection is in-

stalled: every month test the safety of the circuit by press-

ing the Test button of the circuit breaker. The protection ought

to trip. If it does not, call a technician immediately, as the safety

of the equipment is impaired.

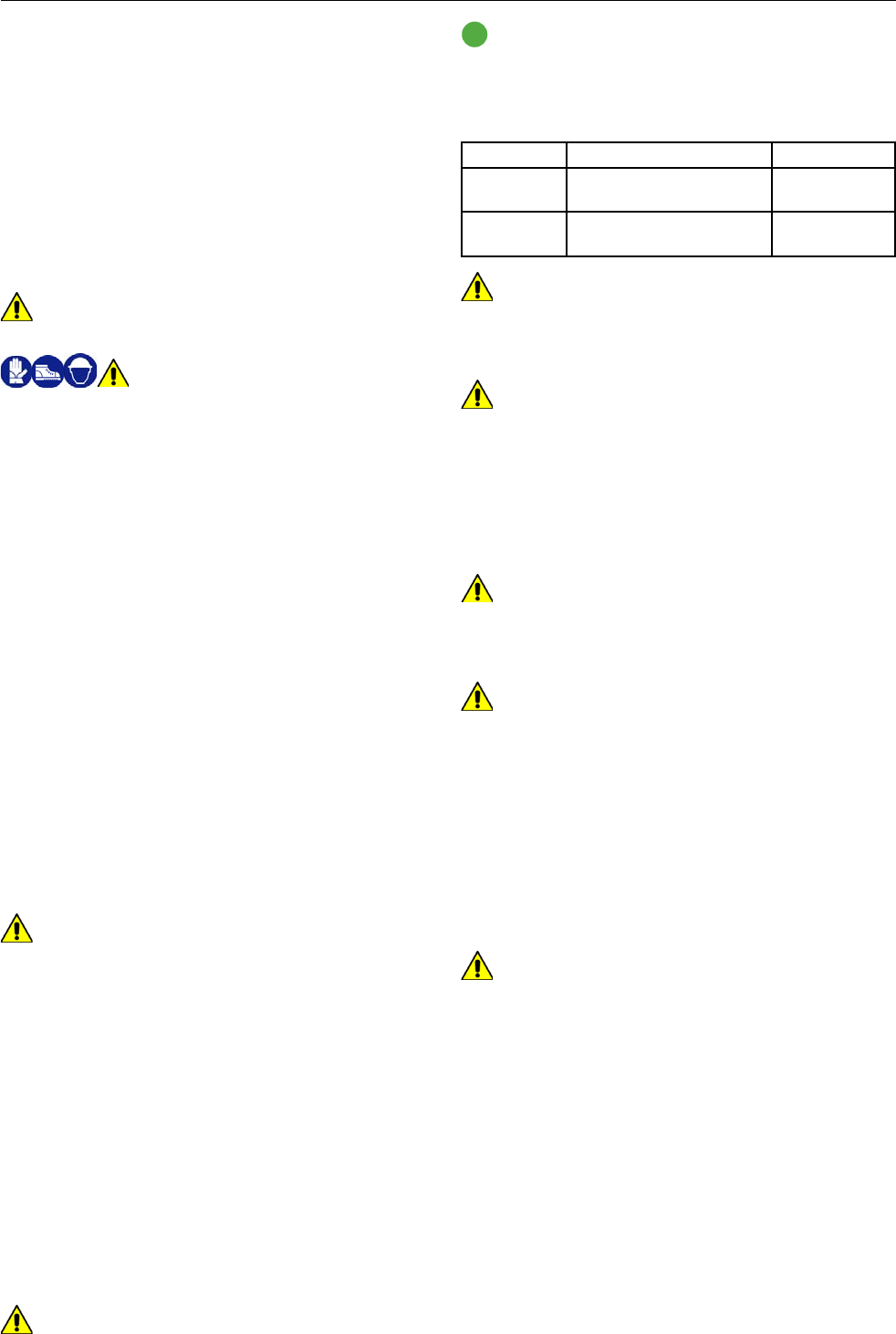

Table 3.5 - Data for electric connection

Installation Plug Power cord

400V 50Hz

Plug 3P+N+T 400V 3N 16A

as per standard IEC60309

Type H05VV-F

5 x 1,5mm

2

210-240V

60Hz

3P+T 210-240V 3 25A Type H05VV5-F

4 x 14AWG

WARNING - The power cord can be replaced only by an

authorised service center.

3.4. Compressed air connection

WARNING - The steam connection is to be made by a li-

censed technician only and according to local safety regu-

lations.

Refer to Figure 3.4.

1. Connect the machine to a compressed air source with pressure

6 bar (90 PSI) minimum

2. Make connections as indicated

3. Set the general pressure regulator on the machine at 6 bar (90

PSI)

WARNING - Do not set the pressure higher than 6 bar.

Risk of damage to the machine.

3.5. Steam connection

WARNING - The steam connection is to be made by a li-

censed technician only and according to local safety regu-

lations.

Refer to Figure 3.5.

Connect the machine to a steam source with steam pressure at 5 bar

(75 PSI) capable of providing 30 Kg/h (66 lbs/hr) of steam.

The numbers in the figure indicate the following parts (not supplied

with the machine):

1 – Steam line

2 – Condensate return line

3 – Ball valve

4 – Check valve

5 – Steam trap

WARNING - Do not connect the machine to a steam line

having pressure exceeding recommended values. Risk of

serious damage to the machine and injury to people.

Installation

3. Installation

3.1. Upon receiving the goods

The machine is delivered mounted on crate and protected by a plastic

film and, in some cases, by a cardboard box.

1. Position the crated machine near to the final location of in-

stallation. The crated machine must be moved using suitable

devices, such as a forklift (Figure 3.1)

2. Unpack the machine and separate cardboard from plastic. Dis-

pose of carton and plastic according to local regulations.

3. Unscrew the bolts that fix the machine to the crate

4. Move the machine from the crate to its final position.

CAUTION - To avoid damaging the machine, do not move

the machine by grabbing the form or the clamps.

CAUTION - The machine can be moved by

hand by experienced personnel only. Wear

gloves, helmet and protective shoes when moving the ma-

chine.

3.2. Packing list

The package contains:

1. Machine, complete with all mechanical parts and tensioning

devices.

2. Plastic bag containing covers and padding (if not already in

place on the machine).

3. Mirror.

4. Instruction manual.

5. Boxes of optional items ordered with the machine (if any)

Upon receiving the goods, check that the package contains all the

above listed items.

3.2.1 Assembling disassembled parts

The machine is supplied with the control panel folded against the side

of the machine. Rotate the support of the control panel to bring it in

the most comfortable position.

Mount the mirror on the machine cabinet (see Figure 3.2):

1. Loosen the screws that hold support (2) in place;

2. Insert the tube (1) into the support (2);

3. Choose the right position for the mirror and tighten the

screws.

3.3. Electrical connections

WARNING - The electrical connection is to be made by

a licensed electrician only and according to local safety

regulations.

The manufacturer is not responsible for damage or injury caused by

improper installation.

Refer to Figure 3.3.

1. Install a multi-pole switch (circuit breaker) to facilitate installation

and service operations. See table 3.5 for rating and type of

connection.

2. In most countries the circuit breaker should include a

protection against overcurrents (e.g. thermal-magnetic circuit

breaker or fuse). If using a fuse, see power absorbtion on

the identification plate of the appliance (see figure 2.1).

In some countries the circuit breaker must include a ground

fault interrupt protection.

3. Mount a plug on the power cord, see table 3.5 for rating

4. Connect the plug to the circuit breaker. The cable should hang

in a gentle curve.

5. Check that the motor is rotating counterclockwise, otherwise

switch two of three phases wires.

WARNING -The electrical line must be properly grounded

to insure the safety of the operator.

F4VA1-ed3605

F4VA1