ENGLISH 9

Battery-Powered Systems Installation Guidelines

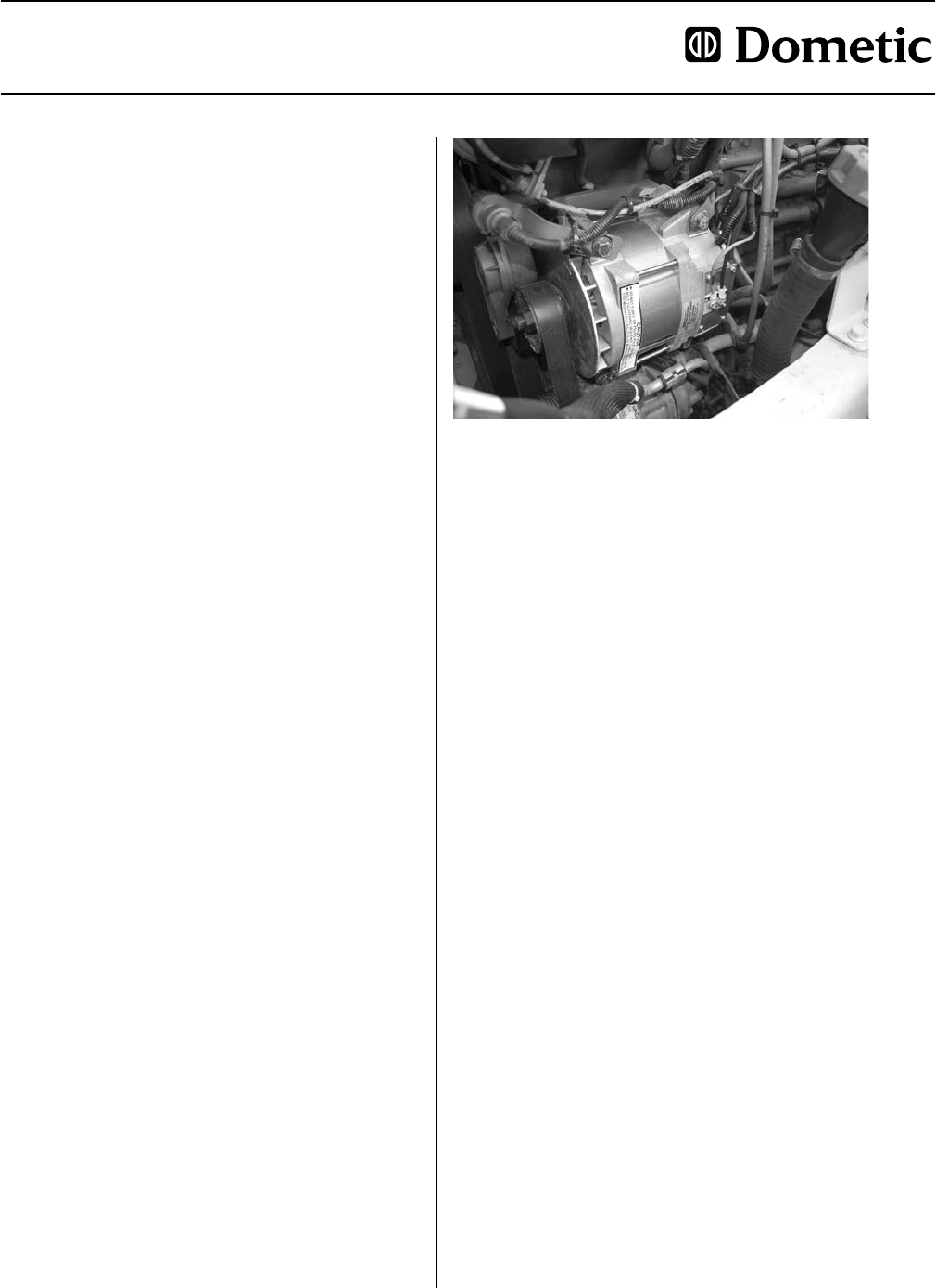

Figure 6 – Alternator installed

INSTALLING THE ALTERNATOR

Follow the instruction manual included with the

alternator/regulator. Here are a few additional tips.

The new alternator should directly replace the existing

one (Fig. 6) (i.e., pad mount or J180 mount). If not, you

need to request the correct model.

The alternator amp rating is based on the number

of batteries in your system and may be different on

different applications.

You will have to reuse the alternator pulley.

Alternator power wiringmay haveto be upsizedor

paralleledwithanadditionalcableiftheOEMcable

sizeisnotabletoconducttherequiredcurrent.Refer

to the alternator literature for guidance.

The negative cable must be attached to the negative

terminal on the alternator and the negative terminal on

a battery.

It must not go just to chassis ground.

Secondary chafe protection (wire loom) is

recommended on AT LEAST the positive conductor. It

is also recommended that chafe protection be placed

in chafe-prone areas on the negative wire.

If you make your own cables, either crimp the end on

the cable with the correct tool or solder it on. There

are cable ends available with the solder already in the

end. Either way, it is suggested that the connection

be covered with heavy-duty heat shrink. This helps

to prevent corrosives from being wicked up into

the copper strands where they can cause hidden

corrosion.

Makedouble surethat allconnections aretight,as

loose connections can cause the regulator not to

work correctly.