www.desatech.com

108661-01F

12

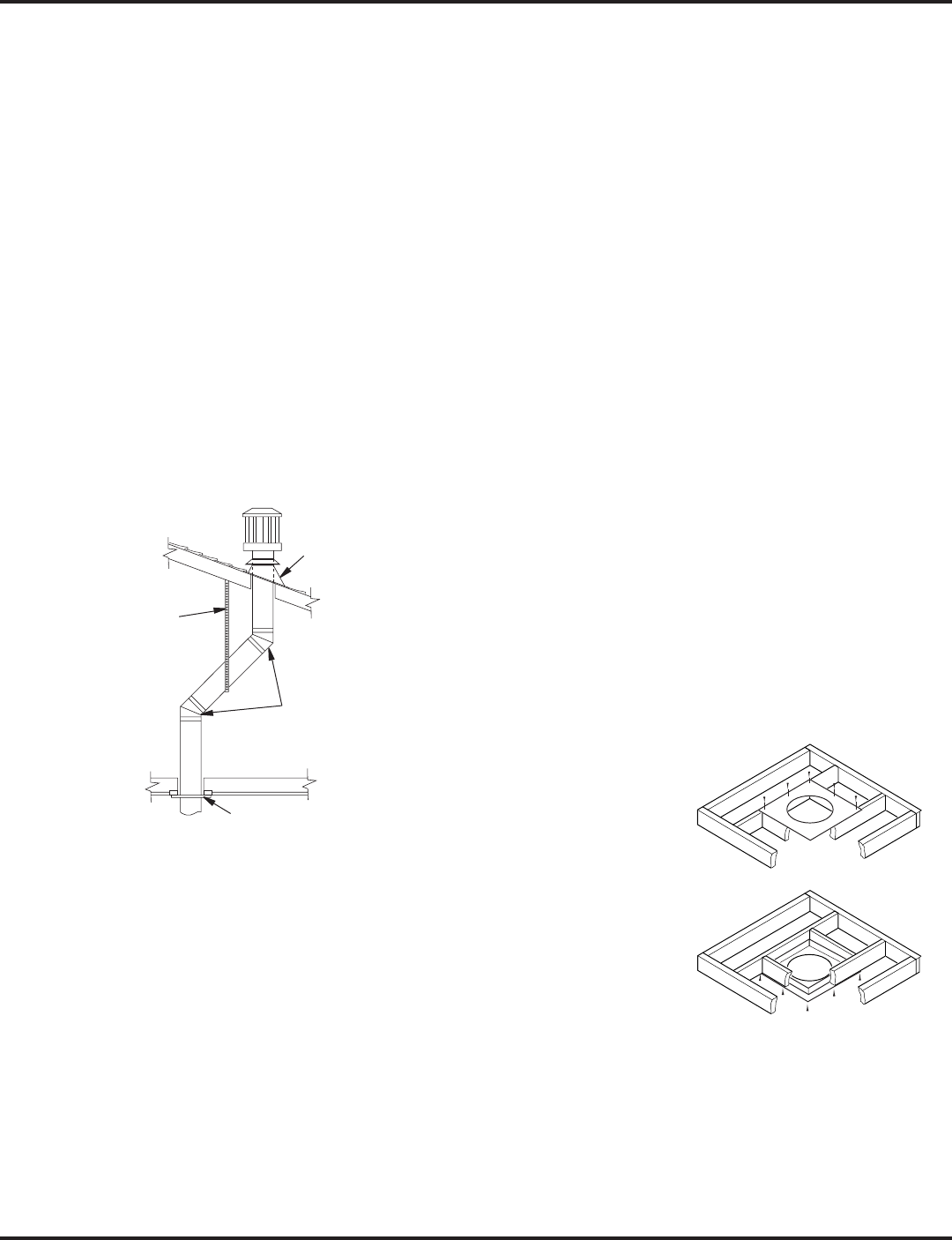

Note: Vertical restrictor must be installed in all vertical installations.

1. Determine the route your vertical venting will take. If ceiling

joists, roof rafters, or other framing will obstruct the venting

system, consider an offset (see Figure 19) to avoid cutting

load bearing members. Note: Pay special attention to these

installation instructions for required clearances (air space)

to combustibles when passing through ceilings, walls, roofs,

enclosures, attic rafters, etc. Do not pack air spaces with insu-

lation. Also note maximum vertical rise of the venting system

and any maximum horizontal offset limitations.

2. Set the replace in desired location. Drop a plumb line down

from the ceiling to the position of the replace exit ue. Mark

the center point where the vent will penetrate the ceiling. Drill

a small locating hole at this point.

Drop a plumb line from the inside of the roof to the locating

hole in the ceiling. Mark the center point where the vent will

penetrate the roof. Drill a small locating hole at this point.

VENTING INSTALLATION

INSTRUCTIONS

Continued

1. Cut a 10" square hole in the ceiling using the locating hole

as a center point. The opening should be framed to 10"x10"

(254 mm x 254 mm) inside dimensions, as shown in Figure 9

on page 8 using framing lumber the same size as the ceiling

joists. If the area above the ceiling is an insulated ceiling or an

attic space, nail restop from the top side. This prevents loose

insulation from falling into the required clearance space. If the

area above the ceiling is a living space, install restop below

the framed hole. The restop should be installed with no less

than three nails per side (see Figure 20).

Figure 19 - Offset with Wall Strap and 45° Elbows

Figure 20 - Installing Firestop

If area above is a living

space, install restop

below framed hole.

If area above is an attic

space or insulated area,

install restop above

framed hole.

2. Assemble the desired lengths of pipe and elbows necessary to

reach from the replace ue up through the restop. Be sure all

pipe and elbow connections are fully twist-locked (see Figure

8, page 8).

3. Cut a hole in the roof using the locating hole as a center point.

(Cover any exposed open vent pipes before cutting hole in

roof.) The 10" x 10" hole must be measured on the horizontal;

actual length may be larger depending on the pitch of the roof.

There must be a 1" clearance from the vent pipe to combustible

materials. Frame the opening as shown in Figure 9, page 8.

4. Connect a section of pipe and extend up through the hole.

Note: If an offset is needed to avoid obstructions, you must

support the vent pipe every 3 feet. Use wall straps for this

purpose (see Figure 19). Whenever possible, use 45° elbows

instead of 90° elbows. The 45° elbow offers less restriction to

the ow of the ue gases and intake air.

5. Place the ashing over the pipe section(s) extending through

the roof. Secure the base of the ashing to the roof and framing

with roong nails. Be sure roong material overlaps the top

edge of the ashing as shown in Figure 19. There must be a

1" clearance from the vent pipe to combustible materials.

6. Continue to add pipe sections until the height of the vent cap

meets the minimum building code requirements described in

Figure 7 on page 6. Note: You must increase vent height for

steep roof pitches. Nearby trees, adjoining roof lines, steep

pitched roofs, and other similar factors may cause poor draft

or down-drafting in high winds. Increasing the vent height may

solve this problem.

7. Twist-lock the vent cap onto the last section of vent pipe.

Note: If the vent pipe passes through any occupied areas above the

rst oor, including storage spaces and closets, you must enclose

pipe. You may frame and sheetrock the enclosure with standard

construction material. Make sure and meet the minimum allow-

able clearances to combustibles. Do not ll any of the required air

spaces with insulation.

45° Elbow

Wall Strap

Roof Flashing

Ceiling Firestop