CertainTeed Vinyl Siding Installation Guide

129

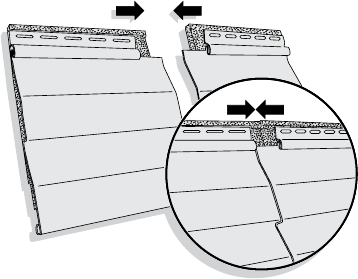

Overlapping panels

On factory-cut panels, the foam is set back from both ends of the

panel. The adhesive begins 2" back from the end of the foam.

To correctly overlap the panels, slip the vinyl edge of the bottom

portion of the seam between the foam and the vinyl panel.

For standard length CedarBoards, slide the panels together until

the foam ends touch or you achieve a minimum overlap of 1". The

maximum overlap should not exceed 1-1/2" because exceeding

an overlap of 1-1/2" can compromise the appearance of the lap.

For CedarBoards XL:

• Above 40°F, overlap the panels 1-1/4" to 1-3/4"

• 40°F and below, overlap panels 1" to 1-1/2" and leave

a 1/4" space between the foam

TIP: For ease of handling extended length product,

we recommend carrying the panels on edge, not flat.

Two-person installation is also suggested.

Measuring CedarBoards

When lapping two factory laps, you will often butt the panel foam

and not lap 1" as in standard vinyl applications. This mandates

a different approach from standard practice when you measure

CedarBoards panels.

When filling in a piece to end a course of siding, hold the tape

tight into the receiver of the corner post, J-channel, etc., and

measure the distance to the foam of the existing piece already

hung. Subtract the proper amount for expansion and contraction,

depending on the temperature.

As you measure on the full piece to be cut, measure from the foam

on the factory end that butts to the existing piece to your desired

measurement. This will ensure a butt fit on the foam and the

proper room in the receiver for expansion and contraction.

Creating a field lap

For best appearance, lap factory ends only. If you must lap a non-

factory end, you will first have to remove the foam and adhesive.

Cut the foam back approximately 3/4" on the field cut, fabricate

the top and bottom panel end notches, and always use a factory

notch as the overlapping panel. Place the field-cut end into the

factory end.