Installation Step 5 I

Hang the Opener

I

:::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::::

::::::::::::::::::::::::::::::::::::::::::::::::::_-:_,3"_,_:-_;_;:;_:_;_ :: :::_:_:_:_::::_:::::::_:_L:"

The opener could fall and injure someone if it

is not properly secured. Fasten the opener

securely to structural supports of the garage.

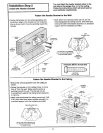

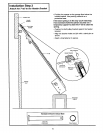

Two representative installations are shown.

Yours may be different. Hanging brackets should

be angled, Figure 1, to provide rigid support. On

finished ceilings, Figure 2, attach a sturdy metal

bracket to structural supports before installingthe

opener. The bracket and fastening hardware are not

provided. See accessory page 38.

• Measure the distance from each side of the opener

to the structural support.

Cut both pieces of the hanging bracket to required

lengths.

Drill 3/16" pilot holes in the structural supports.

Attach one end of each bracket to a support with

5/16"xl 8-1-7/8" lag screws.

Fasten the opener to the hanging brackets with

5/16"-18x7/8" screws, lock washers and nuts.

• Check to make sure the T-rail is centered over the

door (or in line with the header bracket ifthe

bracket is not centered above the door).

• Remove the 2x4. Operate the door manually. If the

door hits the rail, raise the header bracket.

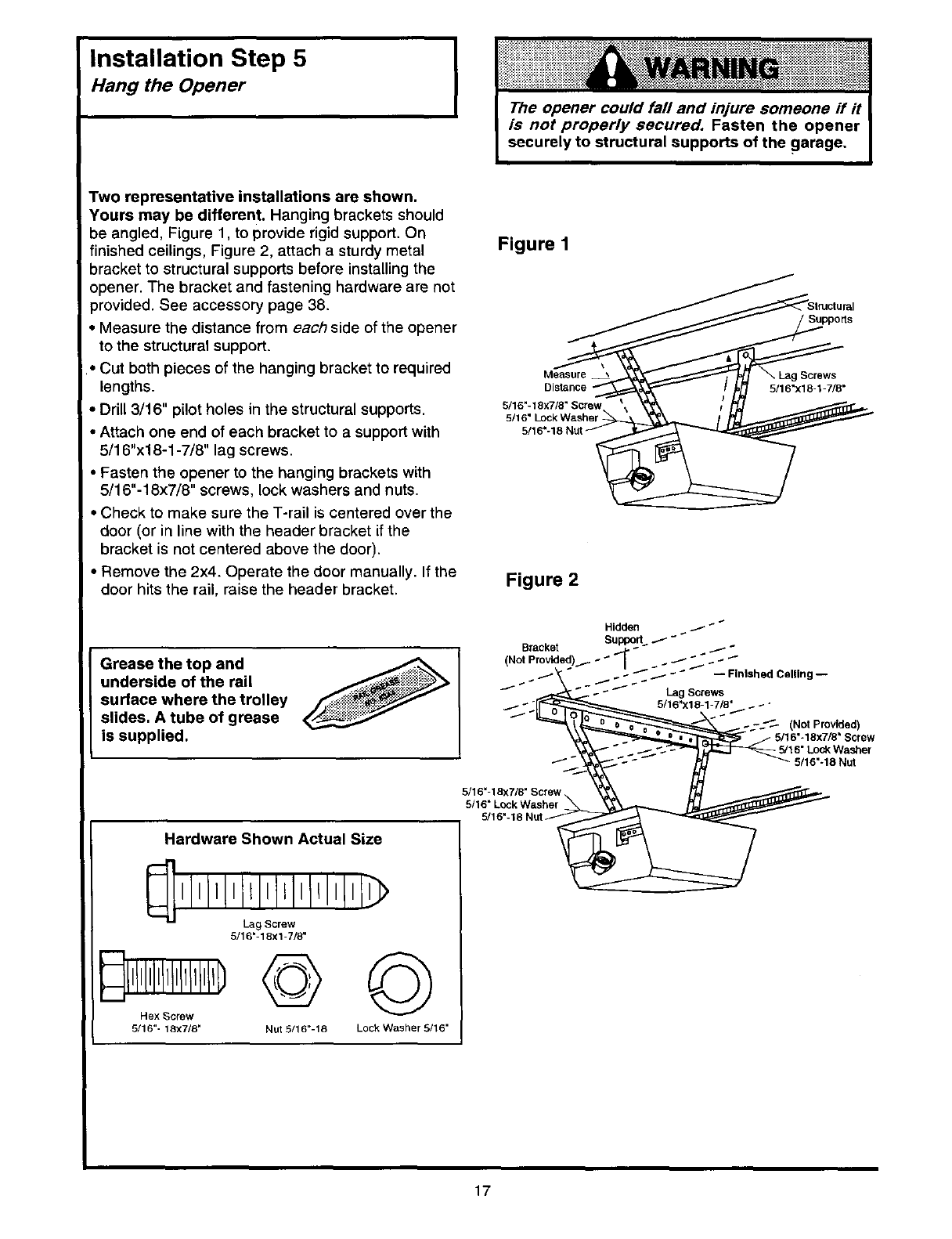

Grease the top and

underside of the rail

surface where the trolley

slides, A tube of grease

is supplied.

Hardware Shown Actual Size

Lag Screw

5/16'-18xl-7/8"

5/16"-18x7/8" Nut 5/16"-18 Lock Washer 6/16"

Figure 1

StrUctural

Supports

Measure __ Lag Screws

Distance 5/16"xl 8-1-7/8"

5/16"-18x7/6" Screw \

5/16" Lock Washer

5/16 *-18NutJ_- J_t_._ /

Figure 2

(Not provided)

/ 5/16"-18x7/8"Screw

" 5/16"-18 Nut

5/16'-18X7/8" Screw

5/16" LOckWasher

17