21

Chateau™

20011956

FP1243a

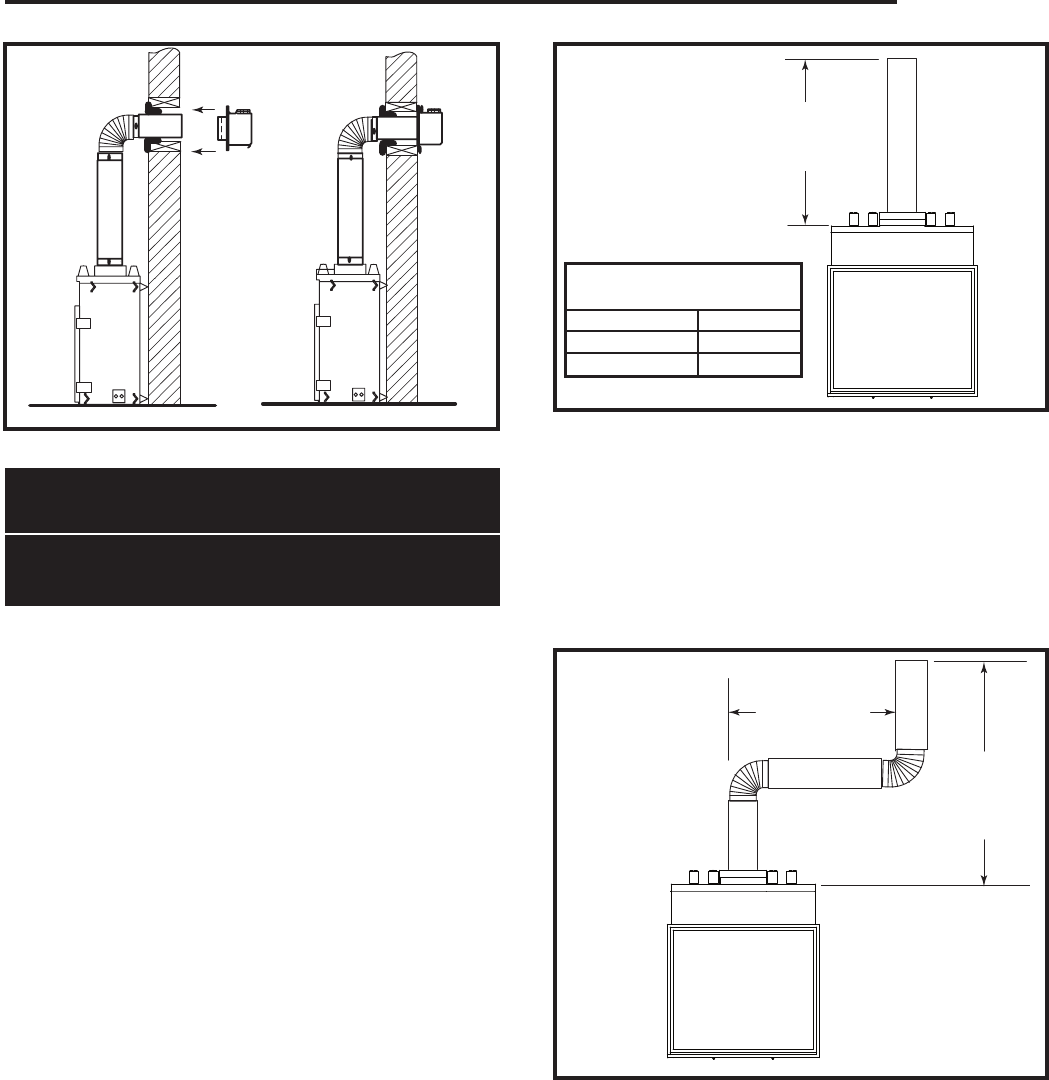

Fig. 25 Secure termination to wall.

Use of Restrictor Plate

for Vertical Venting Applications

The primary purpose for the vent restrictor is to regain

flame height under certain venting conditions as

outlined below.

NOTE: The joints of the inner pipe (flue pipe) must be

taped with 550°F or higher temperature metal adhesive

tape that meets the requirements of F.A.R. 25.853(a)

High temperature sealant milpack or stove cement

of 550°F or higher could be used instead. The joints

of The outer pipe (fresh air pipe) must be taped with

315°F or higher temperature metal adhesive tape or the

use of high temperature milpack or stove cement would

be applicable. When using the unitized 30°, 45° or 90°

elbows, apply 1/4” bead of high temperature, 550°F or

higher, sealant (milpack or stove cement) to the joint of

the inner pipe (flue pipe) and the straight section as it is

impossible to be taped. The outer pipe must be taped

with 315°F high temperature metal adhesive tape for

proper sealing.

For vertically venting either propane or natural gas

units, with vertical vent heights of 12’ (3.7 m) or greater,

(measured from the top of the flue collar) the restrictor

plate as supplied with this unit should be used. (Fig.

26) Also, the fresh air restrictor plate could be adjusted

according to your vent height. (Fig. 26) Refer to Pages

25 & 26, Figures 35 & 37 for restrictor plate installation

and fresh air restrictor plate adjustment.

Vertical Through-the-Roof

Applications

12'

(3.7m)

Min. Rise

10' (3m) Max.

Natural or LP

Use 4"

FP1410

Restrictor plate

horizontal offset installation

8/26/03 djt

Fresh Air Restrictor Plate

Setting = None or #3 Only

FP1410

Fig. 27 Restrictor plate use with horizontal offset.

For vertical venting configurations that include a

minimum vertical rise of 12’ (3.7 m) and a maximum

horizontal offset of 10’ (3 m) the 4¹⁄₂” restrictor plate

supplied with this unit should be used. The fresh air

restrictor plate could be adjusted to the setting #3

(DVT44IN Only). (Fig. 28) Refer to Pages 25 & 26,

Figures 35 & 37 for restrictor plate installation and fresh

air restrictor plate adjustment.

12'

(3.7m)

or Greater

'X'

FP1409

restrictor plate

straight up installation

8/26/03 djt

DVT44 - Natural or LP

Use 6

"

DVT38 - Natural or LP

Use 5"

FP1409

Fig. 26 Restrictor plate use in straight up installation.

Fresh Air Restrictor Plate

X Setting

30’ to 40’ #1

20’ to 29’ #2

12’ to 19’ #3

This Gas Fireplace has been approved for,

• Vertical installations up to 40’ (12 m) in height. Up

to a 20’ (6 m) horizontal vent run can be installed

within the vent system using a maximum of three

(3) 90° elbows. (Fig. 28)

• A 2’ (610 mm) vertical section must be installed

before any offset. A maximum of 20’ (6.1 m) horizon-

tal and three (3) 90° elbows may be installed with a

minimum of 12’ (3.66 m) vertical section above the

flue collar of the unit. (Fig. 28)

Flue Restrictor Plate

(Refer to Page 12 and

Page 22, Figure 35)