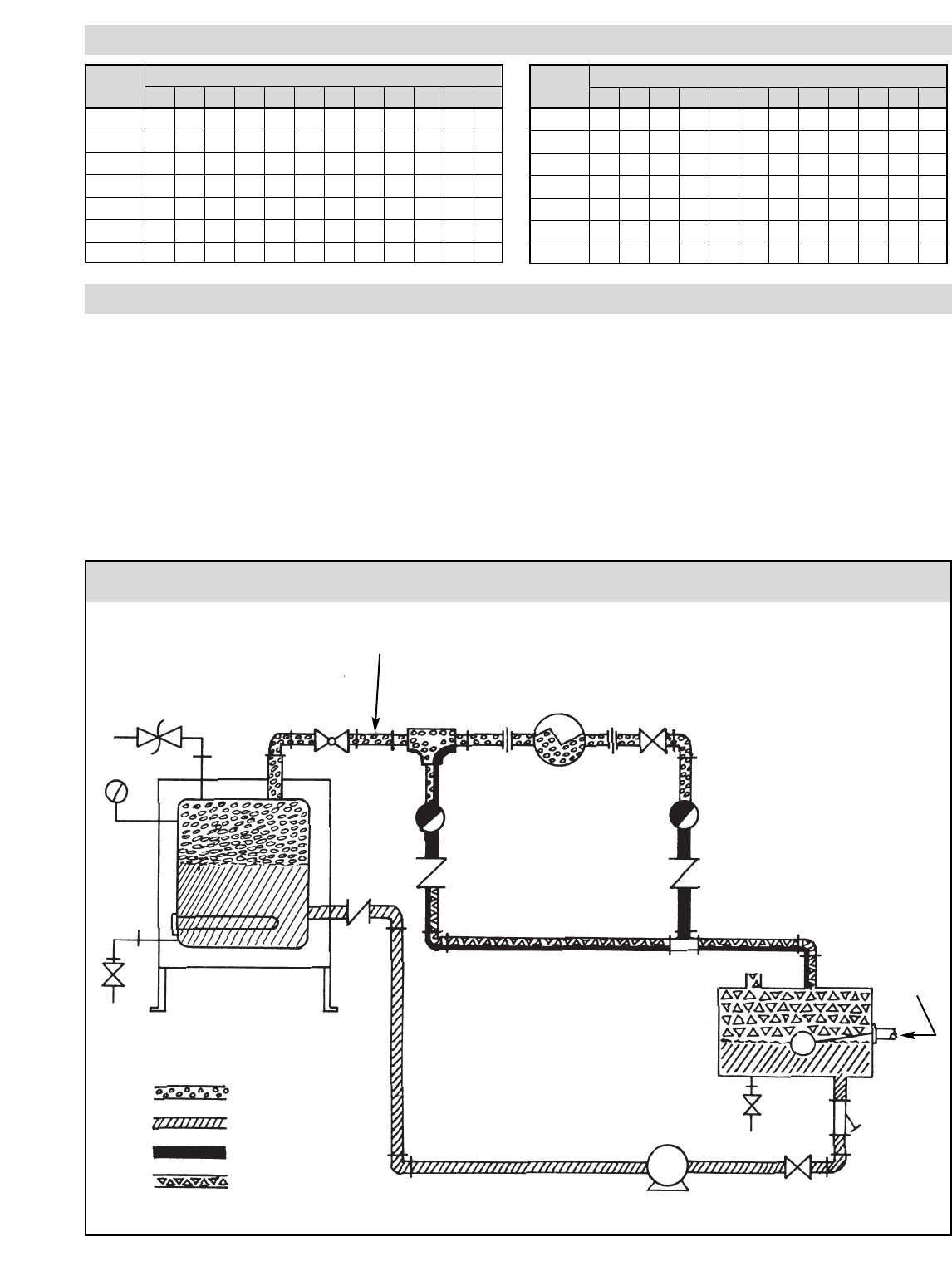

Typical Plumbing Installation of a Steam Boiler with Condensate Return System

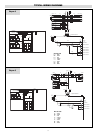

CES — Dimensions (In.)

DIMENSIONS

INSTALLATION

Model A B* C D E F G H I J K L

CES-6 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CES-9 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CES-12 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CES-18 37 22-1/2 30 15-1/4 20 30-1/2 9-1/2 16 1/2 1 1/2 1/2

CES-24 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CES-30 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CES-36 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CES — Dimensions (In.)

Model A B* C D E F G H I J K L

CES-48 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CES-60 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CES-72 43-1/2 26 46 17-1/2 23 34-1/2 16-1/2 24-1/2 1 1 1 3/4

CES-100 63-1/2 30 55 21 27 36 16-3/4 37-1/2 1-1/2 1-1/4 1 3/4

CES-135 63-1/2 32 55 20-1/2 26 37-1/2 16 37-1/2 2 1-1/4 1 3/4

CES-160 63-1/2 32 55 20-1/2 26 37-1/2 16 37-1/2 2 1-1/4 1 3/4

CES-180 63-1/2 32 55 20-1/2 26 37-1/2 16 37-1/2 2 1-1/4 1 3/4

Note: When installing boiler, allow sufficient room (21” minimum) to

facilitate removal of elements if and when necessary.

1. The boiler should be mounted on a solid level foundation.

2. WARNING: A minimum distance of 18” between

boiler and any combustible material must be main-

tained.

3. Complete all piping to boiler. Connect water line to tagged fitting

on the motor and pump assembly, if used, or to tagged fitting on

water control feeder.

4. When any type of feed other than a pump feed is used — the exist-

ing water supply must be 10 pounds greater than the boiler operat-

ing pressure to assure water supply maintains proper water level in

boiler. Otherwise, lack of water can cause heater failure. Keep feed

water line valves open at all times except during blowdown.

5. All water feed systems are connected to water inlet check valve.

6. Connect steam line (with Globe valve) to boiler steam outlet.

Valve should be placed as close as possible to boiler outlet and

sized per label on boiler.

7. To insure maximum efficiency of supplied kW, all piping from

outlet should be insulated.

8. Drain and relief valve piping should be in accordance with state

and local codes. Floor drain to be provided directly below unit.

9. All electrical wiring should be done by licensed electrician in

accordance with national and local electrical codes.

10. If pump is located less than 30 feet from boiler, a second

check valve is required.

Vacuum

Breaker

Safety

Valve

Drain

Boiler

Check

Valve

Check

Valve

Check

Valve

Globe

Valve

Gate

Valve

Heat

Exchanger

Water/Steam

Separator

Insulated Steam Lines

(Pitch Down 5˚)

Pitch Down 5˚

Vent

Condensate

Return

Drain

Gate

Valve

Strainer

Return

Cold Water

Make-Up

Centrifugal

Turbine Pump

Steam

Water

Condensate

Vapor

(Typical

Load)

Trap

Trap

3

*Add two inches for transformer.