Automatic water feed is required on all CES Boilers:

LOW PRESSURE FEED

Note: Water Pressure feeds must be at least 10 psi greater than steam

pressure.

Low pressure water feed systems are used to supply make up

water to the boiler where incoming water line pressure is 10 psig or

greater than the operating pressure of the boiler. It consists of strainer,

solenoid valve and check valve.

Installation

The low pressure water feed systems are optional, and are factory

plumbed and wired to the boiler. However, CES series boilers which

are shipped from stock, the ES-99117 feed is shipped separately for

field installation.

Field Installation

Note: The low pressure feed is to be plumbed to the inlet of the fac-

tory mounted check valve located on the make up water inlet to the

boiler. The plumbing and wiring are to be conducted by licensed per-

sonnel in accordance with national and local electrical codes. For

wiring refer to wiring diagrams supplied with the boiler.

HIGH PRESSURE FEED

High pressure makeup water pumps are used when water pressure

does not exceed boiler pressure by more than 10 psi and when con-

densate water is not returned to the boiler. Note: Consult factory or

sales office for motor/pump sizing for appropriate water feed system.

WARNING: Hazard of Electric Shock. Water feed system

must be effectively grounded in accordance with the

National Electrical Codes to eliminate shock hazard.

Installation

1. Locate feed on level floor or platform.

2. Connect water line to tagged fitting on feed.

3. Connect piping from discharge to water inlet check valve on boil-

er with minimum of 90˚ bends or other restrictions.

4. All electrical wiring should be done by licensed electricians in

accordance with local and national electrical codes. Refer to boil-

er instruction for manual wiring diagram.

5. If pump is located less than 30 feet from boiler, a second check

valve is required.

CONDENSATE RETURN SYSTEMS

Chromalox condensate return systems are used wherever con-

densed steam can be collected for reuse in the boiler. Significant ener-

gy can be saved by returning condensate to the boiler. The condensed

water is free from corroding minerals and carries a substantial amount

of heat which does not have to be replenished.

IMPORTANT: Vacuum breaker is required whenever using a con-

densate return system.

WATER FEED SYSTEMS

Automatic Low Pressure Water Feed

16

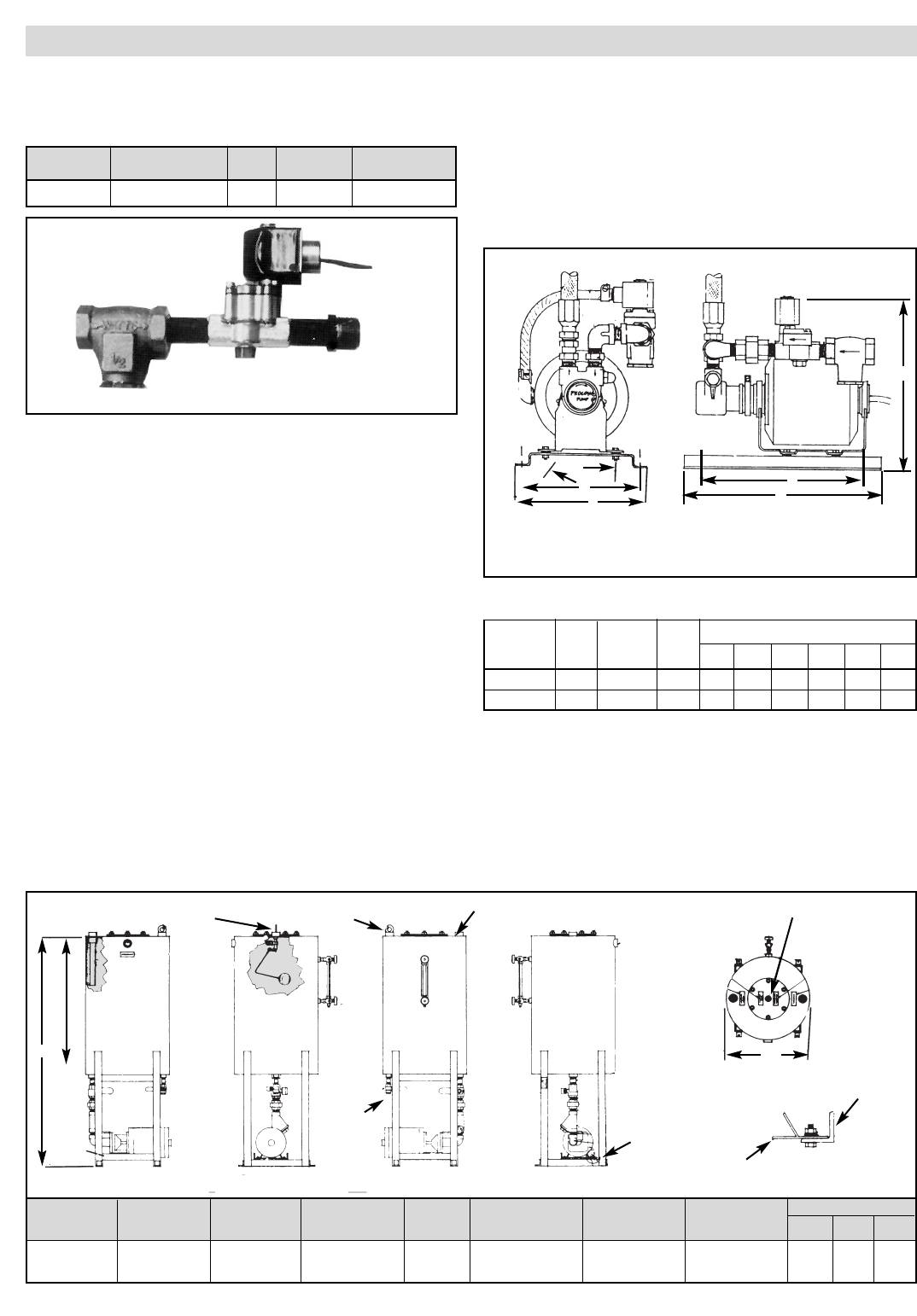

Pipe Dimensions (In.)

Assembly Pressure Size

Model No. H.P. Range NPT A B C D E F

ES-38002 1/3 0-100 1/2” 12 10 11 7-3/8 6-1/2 7-1/2

ES-38020 1/2 0-150 3/4” 12 10 11 7-3/8 6-1/2 7-1/2

Pump Motor Dimensions

Automatic High Pressure Water Feed

Pump Motor and Piping Assembly

D

F

A

B

C

E

1/2" Water Fill

1-1/4" NPT Vent

1-1/4" NPT Cond. Return

1/2" NPT

Drain See Detail

Pump

Support

Leg

Detail Pump Mount

Frame

Member

1/2" Water Fill

18”

H

26 and 33 Gal. Condensate Return System

Condensate For Max Storage Tank Pump Discharge Condensate

Model Boiler Model Pressure (psig) Capacity (Gals.) Pump (hp) Motor (Volts/Phase) Conn. (NPT) Ret. Conn (NPT) L H W

ES38083V CES 12 - 72 100 26 1/3 120 1 1 1 23 46 18

ES38084V CES 100 - 180 100 33 1/2 120 1 1 1 23 52 18

Low Pressure Pressure

Boiler (Solenoid Feed) Volts Inlet (In.) Range

CES Series ES-99117 120 1/2 0-100 psi

Dimensions (In.)