9

Irving Oil

10004000

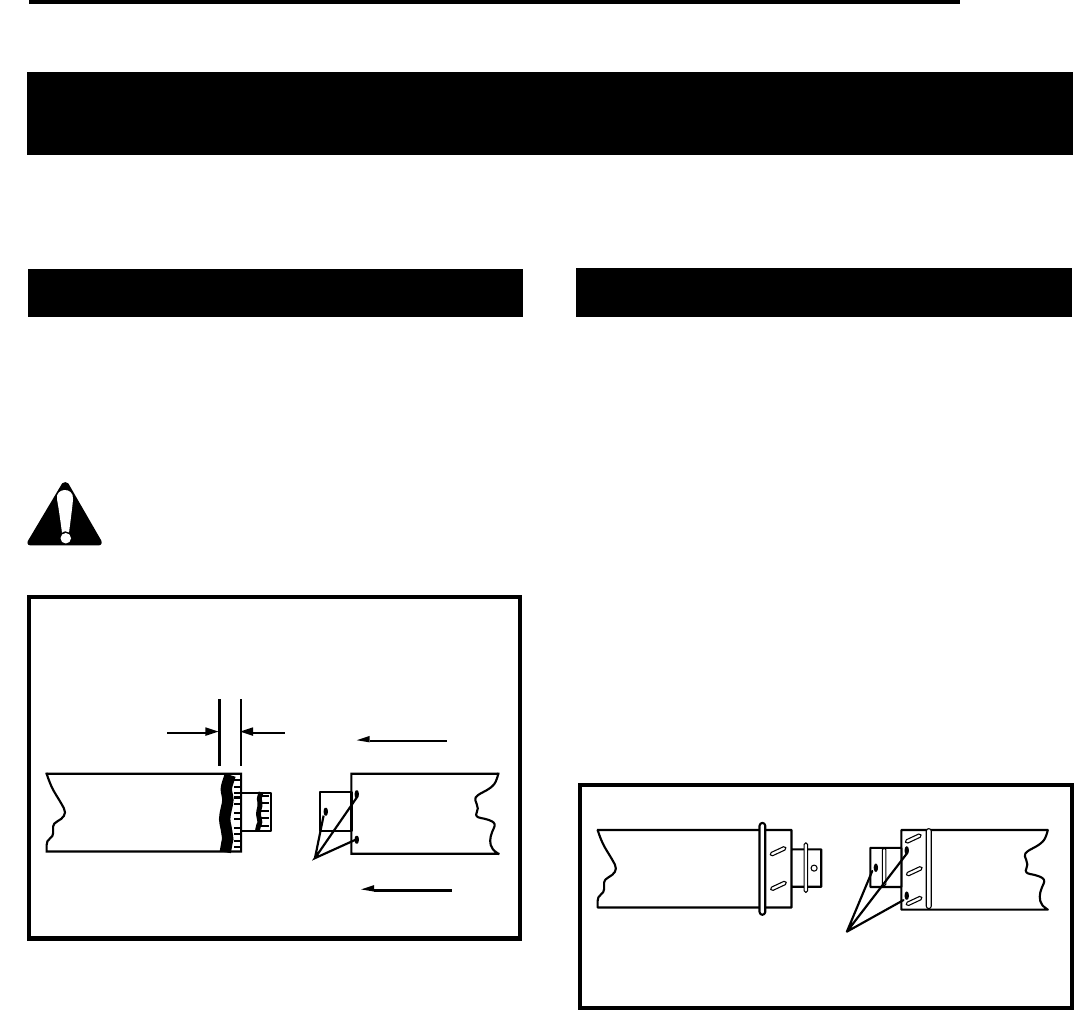

Before joining elbows and pipes apply a bead of high

temperature sealant to the crimped end of the elbow or

pipe. Join the pipes using a 2” (50mm) overlap and

secure the joints with three (3) sheet metal screws

(Fig. 11). Wipe off excess sealant.

There are polished brass decorative

rings available to hide the exposed

piping joints. Wrap the brass ring over

the joint fitting the stud into the notch

and tighten down the 3/8” nut.

GENERAL INFORMATION ON ASSEMBLING

THE VENT PIPES IN DIRECT VENT APPLICATIONS

CANADIAN INSTALLATIONS:

The venting system must be installed in accordance

with the current CSA-B149 (.1 or .2) installation code.

USA INSTALLATIONS:

The venting system must conform with local codes

and/or the current National Fuel Gas code ANSI

Z223.1.

Fig. 11

Screw Holes

Fig. 12

CRIMPED END PIPES

TWIST LOCK PIPES

When using twist-lock pipe it is not necessary to use

sealant on the twist lock joints.

The only areas of the venting system that need to be

sealed with high temperature silicone sealant are the

collars on the fireplace and termination, and the sliding

joint of any telescopic vent section used in the system.

To join the twist lock pipes together, simply align the

beads of the male end with the grooves of the female

end, twisting the pipe until the flange on the female

end contacts the external flange on the male end.

It is recommended that you secure the joints with three

(3) sheet metal screws, however this is not mandatory

with twist lock pipe.

To make it easier to assemble the joints we suggest

putting a lubricant (Vaseline or similar) on the male

end of the twist lock pipe.

BEAD LOCATION

1" FROM CRIMPED END OF PIPE

1''

Screw Holes

NOTE: Only venting components manufactured by The Vermont Castings Majestic Products Company may be used.