19

Irving Oil

10004000

1. It is important to keep the burner and the burner

compartment clean. This must be done

periodically, at least once per season (See

Cleaning Procedure).

2. Clean the brass trim using a soft clean cloth,

slightly dampened with lemon oil and buff with a

soft clean cloth. Do NOT use brass polish or

household cleaners as these products will damage

the brass trim. Lemon oil can be obtained at

supermarkets or hardware stores.

3. The FK24 Fan requires periodic cleaning. Check

the fan and the area around the fan assembly and

wipe or vacuum at least once per month during the

operating season.

4. Contact your local representative to arrange an

annual service program

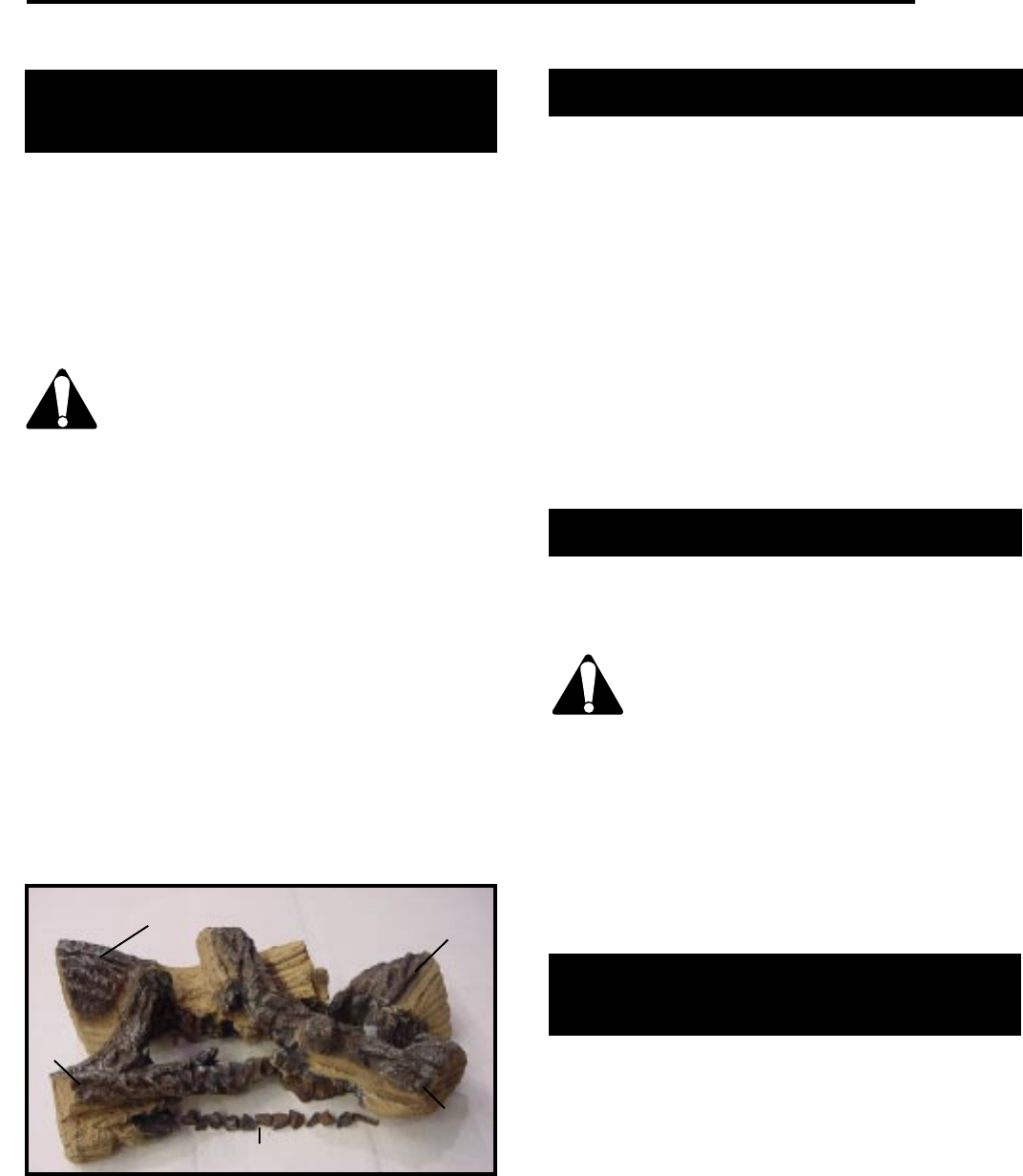

INSTALLATION OF LOGS & BURNER

LAVA ROCK MATERIAL (Cont.)

Model: IRFSDV24

Refer Figure 33.

1. Remove window frame assembly (See Window Frame

Assembly section).

2. Remove logs from packaging.

As with all plastic - these are not toys

and should be kept away from children

and infants.

3. Place rear left log (KR15) with one end onto the

left rear bracket while the rest of the log sets on

the center of the rear log support.

4. Fit the rear right log (KR16) onto the right side of

the rear log support. Ensure the log’s bottom holes

are located on the two studs of the support.

5. Place front left log (KR13) onto the left cut out of

the rear log while the front left end of this log will

set against the back wall of the front grate.

6. Place the front right log (KR14) in position by

resting the holes under one end of this log located

over the knob on the rear left log while the other

end of the log sets against the right end of the front

grate (See Fig. 33).

7. Place burner lava rock over the front area of the burner.

Fig. 33

Burner Lava Rock

KR14

KR13

KR15

KR16

MAINTENANCE

1. Turn off pilot light at gas valve.

2. Remove window frame assembly.

3. Remove logs.

CAUTION: LOGS MAY BE HOT

4. Vacuum burner compartment especially around

orifice/primary air openings.

5. Reinstall logs.

6. Check pilot and main burner operation.

7. Reinstall window frame assembly.

8. Recheck pilot and main burner operation.

9. Check visually the flame pattern and compare

with Figs. 34, 35, & 36.

CLEANING PROCEDURE

FLAME & TEMPERATURE

ADJUSTMENT RFN/RFP

All adjustments on units fitted with the Honeywell

Radio Frequency control valve are performed with

the remote transmitter. See instructions packaged

with the transmitter, or page 23 in this manual for

operating details.