22

Dutchwest

7001219

3. Apply a thin bead of stove cement in the newly-

cleaned groove.

4. Lay the gasket into the groove. Wait until you are a

couple inches from the end before you cut it.

5. Test the gasket by closing the door on a slip of paper

as described above. Adjust the gasket in any areas

where an inadequate seal is evident.

All rope-type gasketing used in the Dutchwest Con-

vection Heater is made of fiberglass. The gasketing is

7/16” diameter for front and side doors and the ash

door and 3/8” for the top plate. 1/4” gasketing is used

behind the glass.

Repair Missing Cement in Seams

The cement in the stove seams may deteriorate over

time and fall out in places. Just as with the stove doors,

it is necessary to keep the seam seals in good condi-

tion. Spot-fix with furnace cement (available from your

local dealer) any areas where the cement seal is visibly

deteriorated. Allow 24 hours for the new cement to dry

after “washing down” seams.

Avoid Damaging the Glass Door Panel

Do not abuse the glass by slamming the door or striking

the glass with a log. Never operate your stove if it has

damaged or broken glass. If you need to replace the

glass, use only replacement glass provided by your lo-

cal Dutchwest dealer.

Damper Adjustment

With time, you may need to adjust the damper link-

age to ensure that the damper plate seals tightly when

closed. Test the damper when the stove is cold. When

turned into the closed position, the damper should be

feel “snug” but not too tight. It will become a little tighter

as the stove heats up. Use a 7/16” socket wrench with

socket extension to adjust the linkage:

1. In an alternating pattern, first loosen and then re-

move the four bolts that secure the top plate to the

sides of the stove.

2. Open the damper.

3. Loosen the adjusting bolt’s lock nut. (Fig. 28)

4. Loosen the anchor bolt’s lock nut, located on the

underside of the damper.

5. Loosen the anchor bolt a turn or two.

6. Tighten the adjusting bolt.

7. Test the damper. Make further adjustments if neces-

sary.

8. When final adjustment has been made, tighten the

adjusting bolt lock nut, the anchor bolt, and the an-

chor bolt lock nut.

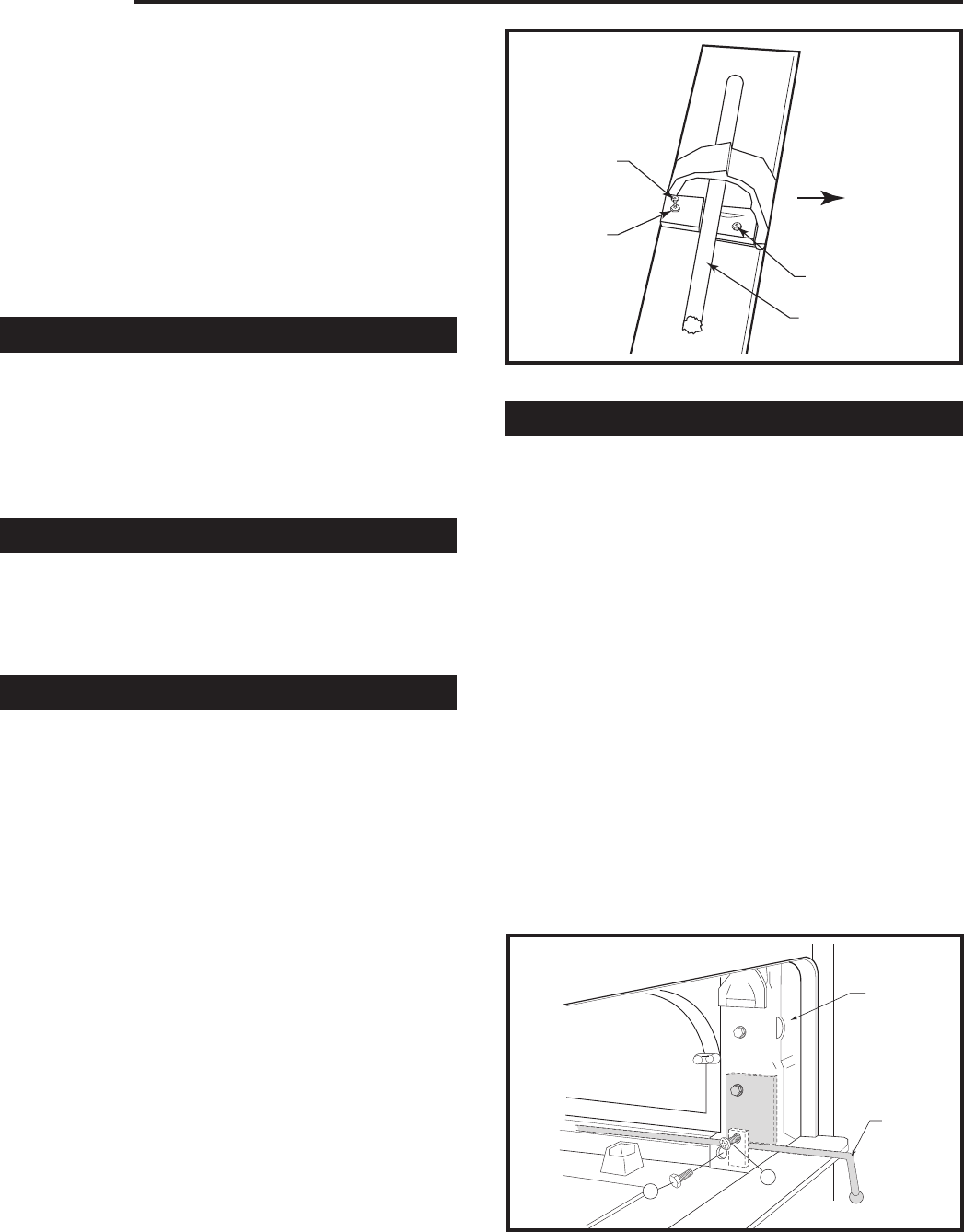

Primary Air Control Adjustment

A simple spring-loaded tab maintains tension on the

primary air control lever. The air control should be loose

enough for you to easily set its position by hand, but

also snug enough to remain in that position until you

change it.

Over time, the air control may tighten or loosen. To

adjust the tension on the control, let the stove cool to

room temperature. Open the side-loading door and look

in toward the inner side of the front panel of the stove.

(Fig. 29) Locate the lower hex head bolt (A) on the

primary air manifold, just inside the door. Remove the

bolt with an open end or box end wrench to gain access

to the adjustment screw (B) inside the manifold. Insert

a Phillips screwdriver into that hole and turn the screw

clockwise to increase tension, counterclockwise to de-

crease tension. Make adjustments in small increments

and test the operation. Replace the hex head bolt when

you are done.

Note that the mechanism may tighten slightly as the

stove heats up. Your adjustment should leave the air

control snug, but not overly tight.

ST442

air control adjustment

7/10/00 djt

A

B

Air Manifold

Air Con-

trol

ST442

Fig. 29 Primary air control adjustment.

ST441

damper rod

7/7/00 djt

Adjusting Bolt

Lock Nut

Damper Rod

Anchor Bolt

ST441

Front of

Stove

Fig. 28 Damper adjustment.