32

Defiant Woodburning Stove

30001693

6. If the element is in good condition and clean, re-in-

stall it in the stove and replace the refractory access

cover.

7. Replace the fireback, the five bricks and their clip,

the left and right wedges, and the throat. When you

install the lower fireback, be sure to align the two

slight recesses in its bottom forward edge behind

the mating tabs on the firebox floor. (Fig. 43) When

you install the wedges, be sure to place their rear

vertical edges against the outermost left and right

edges of the lower fireback, to ensure a good seal

between the lower fireback and the stove’s outer

back. Tap them downward to seat them snugly, but

not overly tight.

8. Clean the chimney and chimney connector.

Operate the stove in your usual manner for two weeks,

inspecting the chimney and the chimney connector

frequently during this period.

If creosote does not build up as fast, it is likely that the

performance change was caused by fly ash deposits

on the catalytic element. However, continue the inspec-

tions of the chimney system for a few weeks to ensure

that proper performance continues.

If you continue to find a significant creosote buildup or if

you continue to see excessive smoke from the chimney,

the catalytic element will need to be replaced. Contact

your nearest Vermont Castings’ Authorized Dealer for

information about a replacement element.

NOTE: Use only the replacement catalyst supplied by a

Vermont Castings dealer.

Replace the Stove Gaskets as Needed

Your Defiant uses fiberglass rope gaskets to make

a tight seal between some parts. With use, particu-

larly on moving parts, gaskets can become brittle and

compressed and can begin to lose their effectiveness.

These will need periodic replacement.

The sizes of replaceable gasket are listed below, along

with their applications.

Gasket Diameter... ...And the Parts it Seals

5/16” The griddle to the stove top

(wire reinforced gasket)

5/16” The damper to the upper fireback; the

front doors to the stove front; and the

doors to each other.

3/8” The ash door to the front of the bottom

panel

3/16” The outer glass panes to the door

If you need to change a gasket, first obtain an appropri-

ate replacement from your Vermont Castings, Autho-

rized Dealer.

Wait until the fire is out and the stove has cooled. Be

sure to follow the standard safety procedure for working

with dusty materials: wear safety goggles and a dust

mask.

The procedure for replacing gaskets is the same,

regardless of the gasket location. Follow these eight

steps:

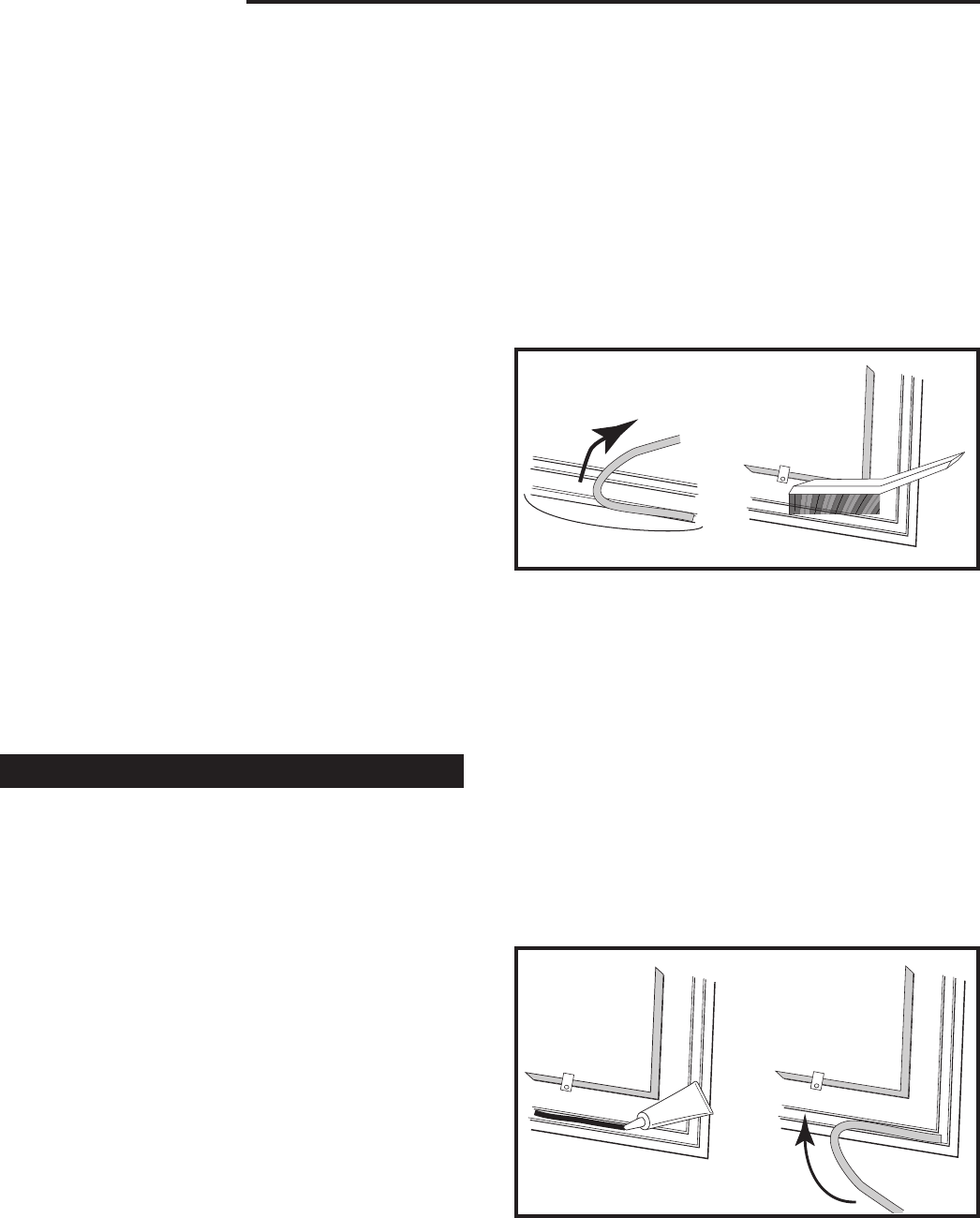

1. Remove the existing gasket by grasping an end and

pulling firmly. (Fig. 47)

2. Use a wire brush or the tip of a screwdriver to clean

the channel of any remaining cement or bits of

gasket. Remove stubborn deposits of cement with a

cold chisel if necessary. (Fig. 47)

ST559

Remove

gasket

11/30/00 djt

Fig. 47 Remove gasket then clean channel with wire brush.

ST560

3. Determine the correct length of the appropriate-sized

gasket by laying it out in the channel. Allow an extra

1-2” (25-50 mm), and mark the spot to be cut.

4. Remove the gasket from the channel, place it on a

wood cutting surface, and cut it at the marked spot

with a utility knife.

Twist the ends slightly to keep the gasket from un-

raveling.

5. Lay an unbroken 1/8” (3 mm) bead of gasket cement

in the newly-cleaned channel. (Fig. 48)

6. Starting at one end, press the gasket into the chan

-

nel. (Fig. 48) Ensure a good joint where the gasket

meets before trimming any excess. Do not overlap

the gasket ends or leave ends with ragged edges.

ST559

Remove

gasket

11/30/00 djt

Cement

Sto

ve Gasket

ST561

Fig. 48 Lay a bead of gasket cement then press gasket in

place.