23

Intrepid 1640 Woodburning Stove

30000830

4. Remove the gasket from the channel, place it on a

wood cutting surface, and cut it at the marked spot

with a utility knife. Twist the ends slightly to discour-

age the gasket from unraveling.

5. Lay an unbroken 1/8" (3 mm) bead of gasket cement

in the newly-cleaned channel.

6. Starting at one end, press the gasket into the

channel. Ensure a good joint where the gasket

meets before trimming any excess. Do not overlap

the gasket ends or leave ends with ragged edges.

7. Press the gasketed part firmly against its normal

mating surface to seat the gasket evenly in its

channel. Close and latch the door to do this; close

the door on a piece of waxed paper to keep the

cement from migrating onto the non-gasketed part,

or tap other parts

8. Clean excess cement from around the channel. Let

the cement that holds the new gasket dry thoroughly.

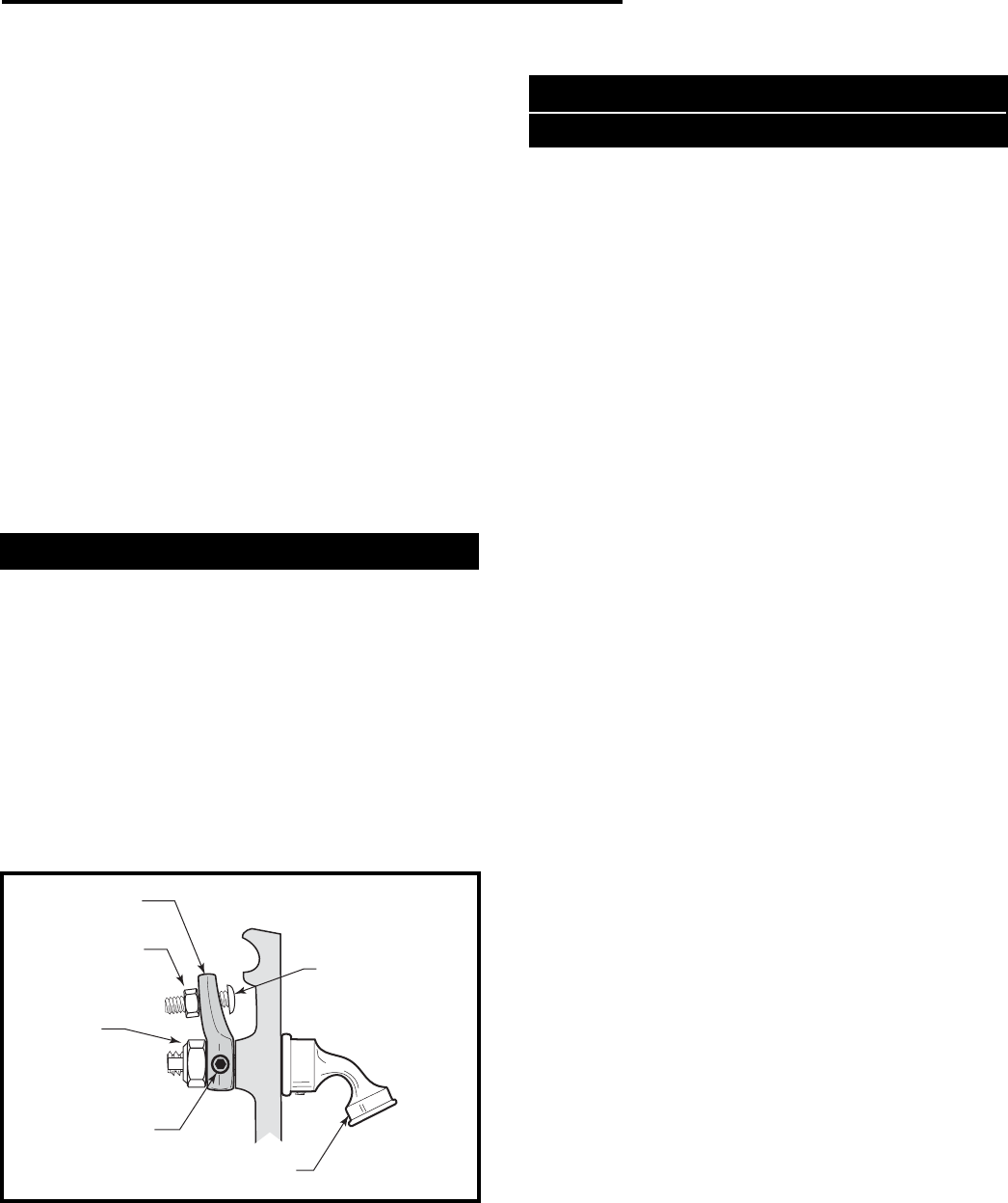

Adjust the Door Latch

Over time, the door latch mechanism may need

adjustment to compensate for compression of the door

gasketing.

1. Using the 5/32” Allen wrench supplied with the stove,

loosen the Small Locknut enough to extend the

Striker Screw one turn clockwise into the Pawl.

2. Retighten the Small Locknut while keeping the

Striker Screw from turning. Test the door latch

closure. You should feel some resistance as you turn

the handle down through the fully closed position.

Make small adjustments as necessary to achieve a

secure latch.

The Chimney System

Creosote

Your Intrepid is designed to reduce creosote buildup

significantly. However, regular chimney inspection and

maintenance must still be performed. For safety, good

stove performance, and to protect your chimney and

chimney connector, inspect your chimney and chimney

connector on a regular schedule. Clean the system if

necessary. Failure to keep the chimney and connector

system clean can result in a serious chimney fire.

When wood is burned slowly, it produces tar,

organic vapors and moisture that combine to form

creosote. The creosote vapors condense in the

relatively cool chimney flue. As a result, creosote

residue accumulates on the flue lining. When

ignited, this creosote makes an extremely hot fire

within the flue system that can damage the chim-

ney and overheat adjacent combustible material.

If you do have a chimney fire, promptly:

• Shut off the air supply by placing the Air

Control lever all the way to the left (LOW).

• Get everyone out of the house.

• Call the Fire Department.

You should inspect the system every two weeks during

the heating season as part of a regular maintenance

schedule. To inspect the chimney, let the stove cool

completely. Then, using a mirror and a strong light,

sight up through the flue collar into the chimney flue. If

it is not possible to inspect the flue system in this

fashion, the stove must be disconnected to provide

better viewing access.

If a significant layer of creosote has accumulated —

1/8" (3 mm) or more — remove it to reduce the risk of

a chimney fire.

Clean the chimney using a brush the same size and

shape as the flue liner. Flexible fiberglass rods are

used to run the brush up and down the liner, causing

any deposits to fall to the bottom of the chimney where

they can be removed through the clean-out door.

The chimney connector should be cleaned by

disconnecting the sections, taking them outside, and

removing any deposits with a stiff wire brush. Reinstall

the connector sections after cleaning, being sure to

secure the individual sections with sheet metal screws.

If you cannot inspect or clean the chimney yourself,

contact your local Vermont Castings’ Authorized

Dealer or hire a professional chimney sweep.

Fig. 36 Door Latch Adjustment

Small Locknut

Pawl

Stricker Screw

Large

Locknut

Set Screw

Handle Stub

ST531