Step 2—Wiring

To prevent personal injury or possible equipment damage,

disconnect the power supply before routing wire.

All wiring must comply with local, state, and national codes.

NOTE: Use No. 18 AWG color-coded, insulated (35°C min)

wire. If thermostats are to be located more than 100 ft from the

WeatherMaker Two-Zone Center as measured along the control

voltage wires, use 16 AWG colored-coded wires to avoid exces-

sive voltage drop. All wiring is run back to the WeatherMaker

Two-Zone Center.

Step 3—Install WeatherMaker Two-Zone

NOTE: WeatherMaker Two-Zone is approved for indoor use

only and should never be installed with any of its components

exposed to the elements. Do not mount WeatherMaker Two-Zone

Center where it will be accessible to children. Do not locate the

center in areas of the home that are noise sensitive since relays are

energized and de-energized during operation and may be an

annoyance. Install WeatherMaker Two-Zone in an area with a

temperature range between 32°F and 150°F.

Install WeatherMaker Two-Zone center in a vertical position.

Locate in an area that is easily accessible in case servicing should

be required.

To prevent possible damage to the WeatherMaker Two-Zone

Center, do not mount on plenum, ductwork, or flush against

furnace.

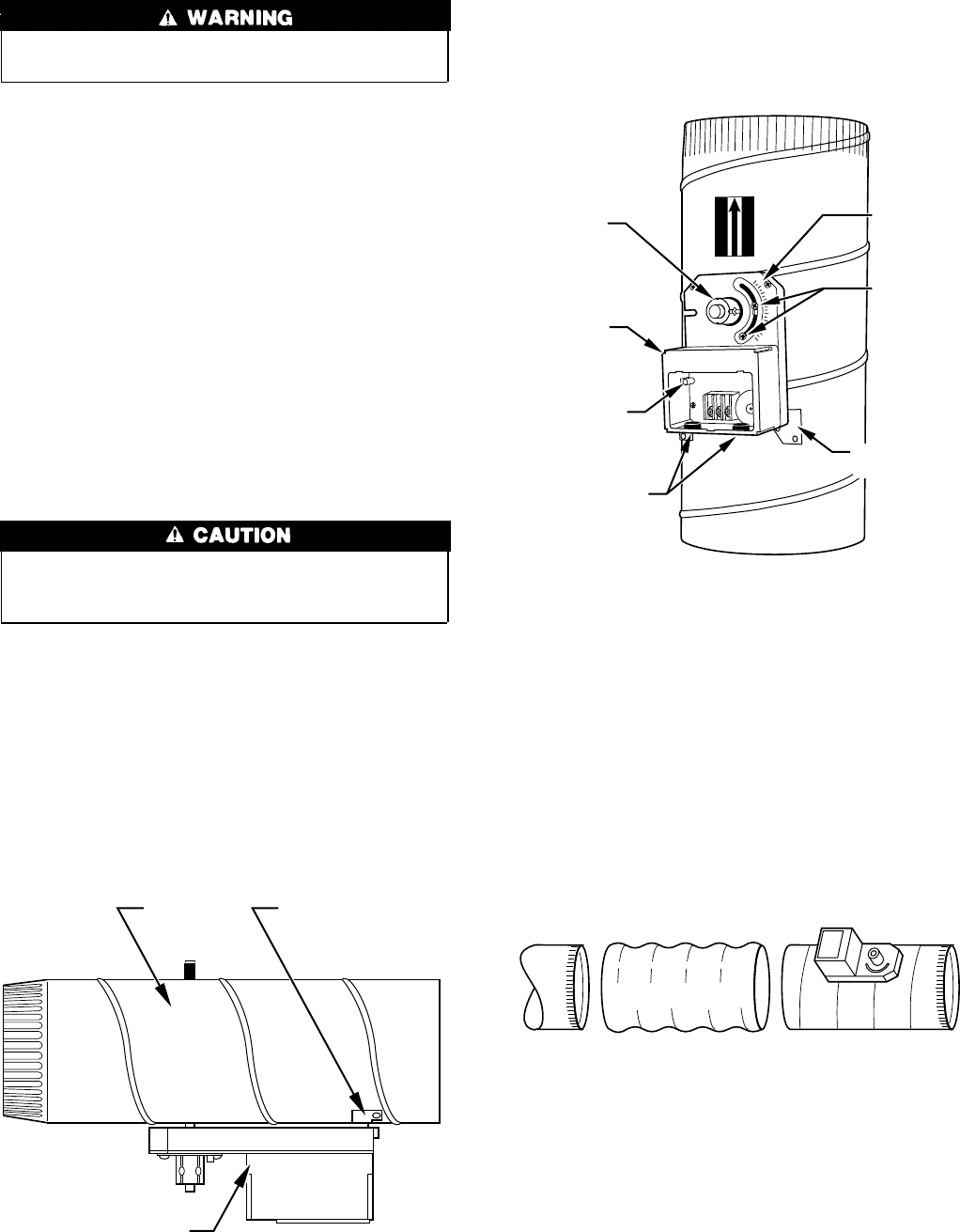

Step 4—Install Zone Dampers

IMPORTANT: If conditions exist for possible condensing, the

motor must be positioned for adequate draining. (See Fig. 2.)

NOTE: If a multi-damper enabler is used to link dampers

together, then add 5va per damper to the transformer power supply

rating. Reference multi-damper enabler Installation Instructions.

Zone dampers may be installed in any direction.

Install dampers so the actuator is visible for inspection and

accessible in the event it would ever need service. The black mark

on the end of the damper shaft represents the position of the

damper blade.

NOTE: Insulate damper using 1-1/2 in. insulation (check local

codes). In areas where excessive condensing may occur, carefully

insulate over the actuator assembly. Make sure insulation does not

interfere with operation of actuator.

Before insulating the ductwork, check for proper damper opera-

tion. Apply 24vac between COM and OPN to open the damper and

COM and CLS to close the damper. (See Fig. 3.) The damper will

modulate counter-clockwise to open and clockwise to close.

If in an emergency it becomes necessary to force a damper open

manually, press in red quick blade release button with 1 hand and

turn mounting hub to reposition the damper shaft. Release button

to hold damper shaft in the new position.

To avoid noise and vibration, do not hard mount dampers to any

solid structure such as joists.

ROUND METAL DUCTWORK

IMPORTANT: If application exists with all metal ductwork

without insulation, flex connectors should be used on each end of

the zone dampers to avoid noise and vibration.

1. Crimp end of branch duct.

2. Slip end of flex connector over zone damper and use self-

tapping sheet metal screw to secure. (See Fig. 4.)

3. Properly seal joint using duct tape, mastic, or other approved

method. Do not allow mastic to come in contact with actuator.

4. Insulate damper using 1-1/2-in. to 2-in. insulation. (Check

your local codes.) (See Fig. 5.)

NOTE: All zone dampers and ductwork must be properly sup-

ported according to local codes or SMACNA standards.

RECTANGULAR METAL DUCTWORK

1. Make connections using S-lock and drives. (See Fig. 6.)

Fig. 2—Damper Motor Positioning

A95128

DAMPER MOUNTING

BRACKET

ACTUATOR

Fig. 3—Damper 24-vac Connections

A95096

90

45

0

CLS

COM

OPN

ACTUATOR

HOUSING

MOUNTING

BRACKET

QUICK BLADE

RELEASE

BUTTON

(RED)

FIELD

INSTALLED

POWER WIRING

ANGULAR

ROTATION

STOPS

POSITION

INDICATOR

MOUNTING

HUB

AIRFLOW

AIRFLOW

Fig. 4—Round Metal Ductwork

A95129

SUPPLY

FLEX

CONNECTOR

ZONE DAMPER

2

→