Charging the System (90MA) - These units are shipped

with a full operating charge. If recharging is necessary

(complete charge lost), weigh in amount of refrigerant

indicated on unit nameplate and in Table 1.

If unit has partial charge, it must be recharged by

removing existing charge and recharging by weighing in

the required amount of refrigerant. (Refer to Table

1A/B/C/2A/B/C)

Charging the System (90MU)

UNIT SIZES 90MU Units - These units, used with remote

condensers, are shipped with a holding charge only. To

charge:

1. Open discharge and liquid service valves.

2. Leak test, reclaim refrigerant and evacuate.

3. Using standard refrigerant charging techniques and

subcooling charts (Figure 11) add refrigerant as required

to maintain proper operating conditions. Subcooling is

determined by subtracting the actual temperature entering

the TXV from the saturated temperature entering the TXV.

IMPORTANT: Charge on both the HIGH and LOW side

simultaneously of idle compressors to prevent axial

loading of the scroll, which may cause a temporary no

start condition for the compressor. If this occurs, leave

the system off for approximately 30 minutes. Attempt

to restart the compressor; internal pressures should

equalize enough to allow compressor to start.

If removing the compressor, evacuate both the HIGH

and LOW side simultaneously.

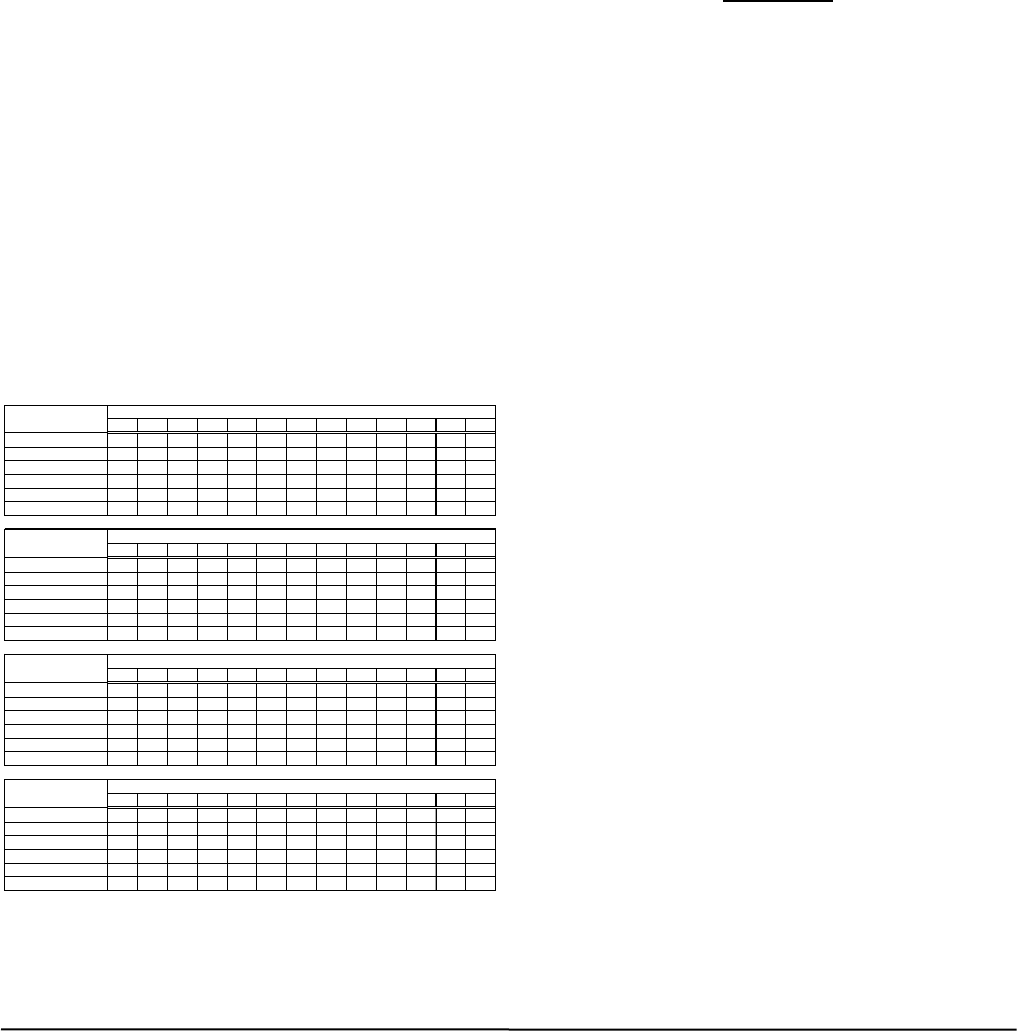

137 149 162 176 205 222 239 256 275 295 315 336 359

0

70 75 80 85 90 95 100 105 110 115 120 125 130

5

65 70 75 80 85 90 95 100 105 110 115 120 125

10

60 65 70 75 80 85 90 95 100 105 110 115 120

15

55 60 65 70 75 80 85 90 95 100 105 110 115

20

50 55 60 65 70 75 80 85 90 95 100 105 110

25

45 50 55 60 65 70 75 80 85 90 95 100 105

150 163 176 190 205 221 237 255 273 292 313 334 356

0

70 75 80 85 90 95 100 105 110 115 120 125 130

5

65 70 75 80 85 90 95 100 105 110 115 120 125

10

60 65 70 75 80 85 90 95 100 105 110 115 120

15

55 60 65 70 75 80 85 90 95 100 105 110 115

20

50 55 60 65 70 75 80 85 90 95 100 105 110

25

45 50 55 60 65 70 75 80 85 90 95 100 105

1100 1200 1300 1400 1500 1600 1700 1800 1900 2000 2100 2200 2300

0

23 26 29 32 34 37 39 42 44 46 48 50 52

3

20 23 26 29 31 34 36 39 41 43 45 47 49

5

18 21 24 27 29 32 34 37 39 41 43 45 47

7

16 19 22 25 27 30 32 35 37 39 41 43 45

10

13 16 19 22 24 27 29 32 34 36 38 40 42

13

10 13 16 19 21 24 26 29 31 33 35 37 39

1190 1288 1392 1503 1580 1701 1786 1918 2011 2107 2206 2308 2414

0

23 26 29 32 34 37 39 42 44 46 48 50 52

3

20 23 26 29 31 34 36 39 41 43 45 47 49

5

18 21 24 27 29 32 34 37 39 41 43 45 47

7

16 19 22 25 27 30 32 35 37 39 41 43 45

10

13 16 19 22 24 27 29 32 34 36 38 40 42

13

10 13 16 19 21 24 26 29 31 33 35 37 39

Required

Subcooling (ºC)

R404A PRESSURE AT LIQUID LINE SERVICE VALVE kPa

Required

Subcoolin

g

(

ºF

)

R407C PRESSURE AT LIQUID LINE SERVICE VALVE PSIG

Required

Subcooling (ºF)

R404A PRESSURE AT LIQUID LINE SERVICE VALVE PSIG

Required

Subcooling (ºC)

R407C PRESSURE AT LIQUID LINE SERVICE VALVE kPa

FIGURE 11 - CHARGING CHARTS

Evaporator-Fan Motor Removal - Motor power wires

need not be disconnected from motor terminals before

motor is removed from unit.

1. Shut off unit main power supply.

WARNING

LOCK OPEN AND TAG unit disconnect

before working on fan motor. Remove fuses

and take them with you after noting this on

tag.

CAUTION

Before attempting to remove fan motors or

motor mounts, place a piece of plywood over

evaporator coils to prevent coil damage.

2. Loosen motor hold down bolts on mounting bracket so

that fan belt can be removed.

3 Loosen but do not remove the 2 motor mounting

bracket bolts on left side of bracket.

4 Slide motor/bracket assembly to extreme right, remove

bolts and lift out through space between fan scroll and

side Rest motor on a high platform such as a step

ladder. Do not allow motor to hang by its power wires.

Pressure Relief Device - All units are equipped with a

fusible-plug type safety relief device an the refrigerant

tubing. The relief setting is 197 °F to 203 °F on all units.

Crankcase Heater - A Crankcase heater is supplied on

90MA,MU*08 and *12 size units. The heater prevents

liquid refrigerant from accumulating in the compressor

crankcase during extended shutdown periods. Heater is

automatically energized whenever unit main power is on

and compressor is stopped. Heater is de-energized when

compressor starts.

Do not shut off main power supply for an extended

period except for servicing unit. Turn on power supply for

at least 24 hours after an extended shutdown before

starting compressor. Refer to “Operation”.

Cycle-Loc

TM

- Protection Device - All units are equipped

with Cycle-LOC current-sensing lockout relay. This device

will lock out the compressor after any safety trip (discharge

pressure switch, suction-pressure switch, or internal

overload of the compressor). Check reason for lockout

before resetting the device. Refer to unit label wiring

diagram. To reset, turn the system switch to OFF, then

back to COOL.

Discharge and Suction Pressure Switches - Refer to

Table 1 for opening and closing settings for these safety

devices.

The discharge pressure switch is located on the

compressor on 06DA compressor equipped units and on

the discharge line on all other units. The suction pressure

switch is located on top of the compressor on 06DA

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 15