Step 12 - Make Electrical Connections

GENERAL - Provide an adequate fused disconnect switch

within sight of the unit. Provision for locking switch open

(OFF) is advisable to prevent power from being turned on

when unit is being serviced.

POWER WIRING - Conduit opening for all units is on left

side of unit near control box. Connect field power wires at

the compressor contactor.

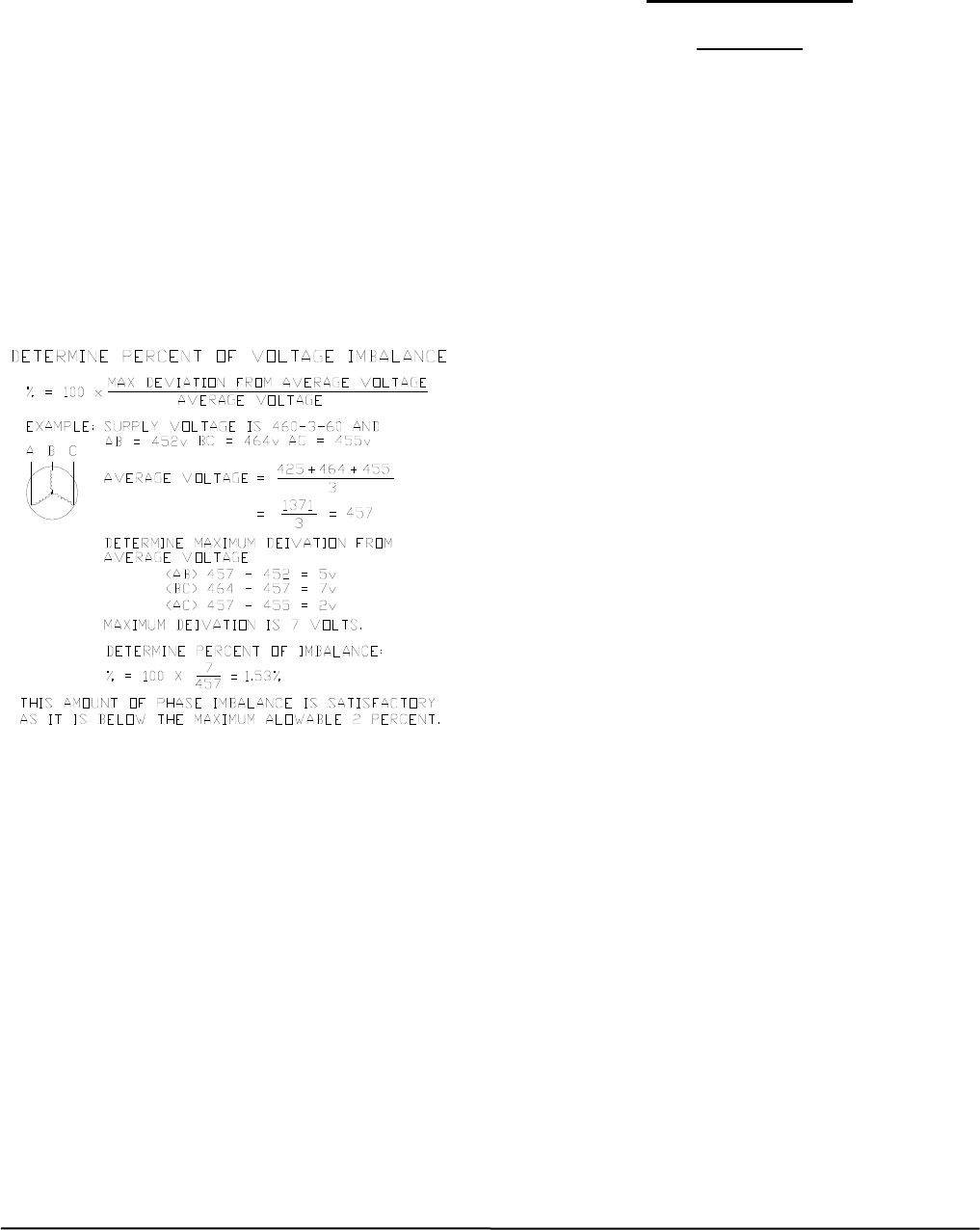

Supply voltage must be in accordance with nameplate

voltage. Voltage between phases must be balanced within

2% and current within 10% with compressor running.

Correct improper voltage or phase imbalance. Unit failure

as a result of operation on improper line voltage or

excessive phase imbalance constitutes abuse and shall

void the Carrier warranty. Use the following formula to

determine the percent voltage imbalance.

CONTROL WIRING - On extended voltage (208/230-v)

units, the control transformer is factory wired for 208-v

usage. If unit is to be used on 230-v system, reconnect

primary wiring on transformer. See Figure 12

(90MA*04/*06) or figure 14 (90MA*08/*12).

On all units, the thermostat is factory installed. A

sensing element is provided in the return air. To wire these

units to a remote thermostat, or to a remote control switch

and thermostat, refer to unit Wiring Diagram or contact

your Carrier Transicold representative.

OPERATION

CAUTION

Compressor crankcase heater must be

energized for 24 hours prior to startup to

prevent compressor bearing damage.

To start unit:

1. Thoroughly inspect exterior of unit. Clean and dust up

debris, then wash with mild soap and water solution.

2. On 90MA*08 &*12 units, ensure compressor

discharge, suction and liquid service valves are open.

(Refer to “Operation - Service Valves.) Check oil level

in compressor sight glass. If level is below glass, add

oil to bring level to approximately 1/4 glass. If level is

above bottom of glass, do not remove any oil until the

crankcase heater has been energized for at least

twenty-four hours.

3. With selector switch in OFF position, turn main power

on. Leave power on for 24 hours so that crankcase

heater can drive off accumulated refrigerant.

4. If desired, the selector switch may be placed in the

FAN position during the crankcase warm-up period. On

first start-up, check fan speed (Tables 1A/B/C/2A/B/C)

and rotation (Figure 1). If fan requires adjustment, refer

to “Service, Evaporator-Fan Adjustment”.

5. Allow crankcase heater to remain energized (unit

power on) for at least 24 hours. Open any valves in

condenser cooling water supply lines and then set

selector switch at COOL position. If room temperature

is above thermostat setting compressor will start. On

first start-up, set water regulating valve. (Refer to

“Service, Water Regulating Valve.)

6. Set thermostat for comfort as desired.

To Shut Down Unit:

1. Turn selector switch to OFF position. Do not shut off

main power except to service unit. The crankcase

heater is operative only when main power is on. (Refer

to “Service, Crankcase Heater”).

2. If unit is to be used for winter heating, set selector

switch at HEAT position and re-set thermostat at

desired setting.

3. If unit may be exposed to freezing temperatures, drain

water from condenser and water piping. Add a non-

corrosive antifreeze to residual water in system.

Service Valves - Always ensure that compressor suction,

and discharge service valves and liquid service valve are

open before operating unit.

The valves are accessible from the front of the unit. To

open valve, turn counterclockwise. After opening, replace

and tighten valve cap to prevent leakage.

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations

Printed in U.S.A. 90MA-3SI SUPERCEDES FORM 62-02971-00 09-2009

Pg 12