40

Air Coil Fan Motor Removal

Disconnect motor power wires from motor terminals before

motor is removed from unit.

1. Shut off unit main power supply.

2. Loosen bolts on mounting bracket so that fan belt can be

removed.

3. Loosen and remove the 2 motor mounting bracket bolts

on left side of bracket.

4. Slide motor/bracket assembly to extreme right and lift out

through space between fan scroll and side frame. Rest

motor on a high platform such as a step ladder. Do not

allow motor to hang by its power wires.

Replacing the WSHP Open Controller’s

Battery —

The WSHP Open controller’s 10-year lithium

CR2032 battery provides a minimum of 10,000 hours of data

retention during power outages.

NOTE: Power must be ON to the WSHP Open controller

when replacing the battery, or the date, time and trend data will

be lost.

1. Remove the battery from the controller, making note of

the battery's polarity.

2. Insert the new battery, matching the battery's polarity

with the polarity indicated on the WSHP Open controller.

TROUBLESHOOTING

(Fig. 32 and 33, and Table 32)

When troubleshooting problems with a WSHP, consider the

following.

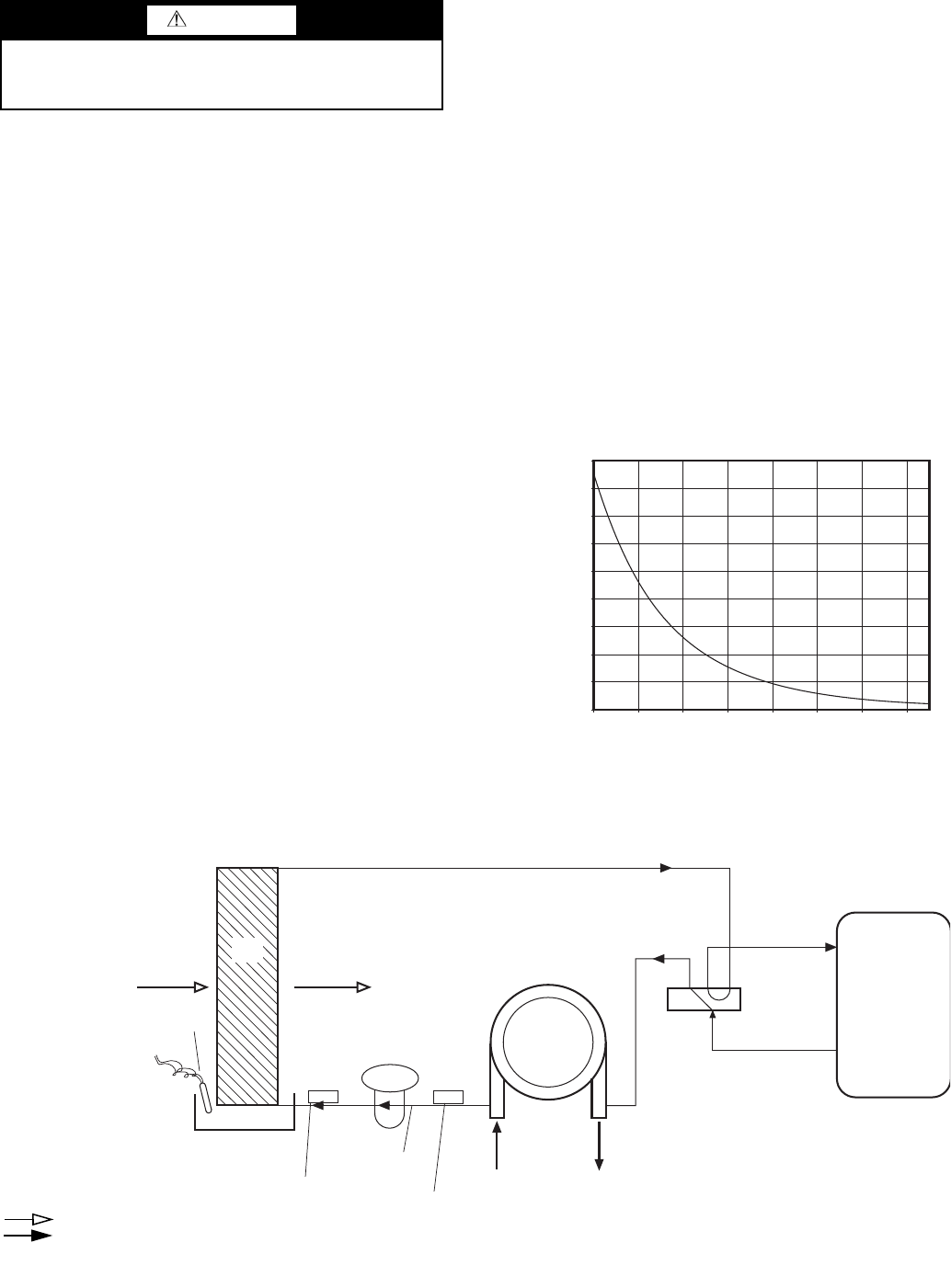

Thermistor — A thermistor may be required for single-

phase units where starting the unit is a problem due to low

voltage. See Fig. 32 for thermistor nominal resistance.

Control Sensors — The control system employs 2 nom-

inal 10,000 ohm thermistors (FP1 and FP2) that are used for

freeze protection. Be sure FP1 is located in the discharge fluid

and FP2 is located in the air discharge. See Fig. 33.

WSHP Open Controller — With the WSHP Open con-

troller option, the 100 most recent alarms can be viewed using

the BACview

6

alarm status and alarm history.

To view the alarms:

1. Navigate to the Alarm Status screen from the Home

screen using the arrow softkeys. The screen will display

the current alarm status, either normal or Alarm, and al-

low for scrolling through the unit’s alarm status.

2. From the Alarm Status screen, press the Alarm softkey to

view the 100 most recent alarms which are labeled with

date and time for easy reference.

NOTE: Active faults can be viewed by scrolling down,

these faults indicate a possible bad sensor or some condi-

tion which may not merit an alarm.

3. To view alarms which have been corrected, scroll down

through the Alarm screen to Return Top Normal screen.

NOTE: Alarms are automatically reset once alarm con-

dition has been corrected.

See Table 32 for possible alarm cause and solution.

CAUTION

Before attempting to remove fan motors or motor mounts,

place a piece of plywood over evaporator coils to prevent

coil damage.

0.0

10.0

20.0

30.0

40.0

50.0

60.0

70.0

80.0

90.0

0.0 20.0 40.0 60.0 80.0 100.0 120.0 140.0

Temperature (degF)

Resistance (kOhm)

Fig. 32 — Thermistor Nominal Resistance

a50-6270ef

SUCTION

COMPRESSOR

DISCHARGE

COAX

EXPANSION

VALVE

FP2

FP1

LIQUID

LINE

WATER IN

WATER OUT

CONDENSATE

OVERFLOW

(CO)

AIR COIL

FREEZE

PROTECTION

WATER

COIL

PROTECTION

THERMISTOR

(°F)

(°F)

AIR

COIL

AIRFLOW

AIRFLOW

LEGEND

Fig. 33 — FP1 and FP2 Thermistor Location

COAX — Coaxial Heat Exchanger

Airflow

Refrigerant Liquid Line Flow

a50-8163