25

Theminimum maintenance requirements for thisequipment areas

follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoor coil, drain pan, and condensate drain each

cooling season for cleanliness. Clean when necessary.

3. Inspectblowermotorand wheelforcleanlinesseach cooling

season. Clean when necessary .

4. Check electrical connections for tightness and controls for

proper operation each cooling season. Service when

necessary.

Step 1—Air Filter

IMPORTANT: Never operate the unit without a suitable air filter

inthereturn--airductsystem.Alwaysreplacethefilterwiththesame

dimensional size and type as originally installed. See Table 1 for

recommended filter sizes.

Inspect air filter(s) at least once each month a nd replace

(throwaway--type) or clean (cleanable--type) at least twice during

each cooling season and twice during the heating season, or

whenever the filter becomes clogged with dust and lint.

Step 2—Indoor Blower and Motor

NOTE: All motors are pre--lubricated. Do not attempt to lubricate

these motors.

Forlongerlife,operatingeconomy,andcontinuingefficiency,clean

accumulated dirt and grease from the blower wheel and motor

annually.

ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal injury

or death.

Disconnectand t agelectricalpowertotheunitbeforecleaning

and lubricating theblower motor and wheel.

!

WARNING

Step 3—Outdoor Coil, Indoor Coil, and Condensate

Drain Pan

Inspect the condenser coil, evaporator coil, and condensate drain

pan at least once each year.

The coils are easily cleaned when dry; therefore, inspect and clean

the coils either before or after each cooling season. Remove all

obstructions, including weeds and shrubs, that interfere with the

airflow through the condenser coil. Straighten bent fins with a fin

comb. If coated with dirt or lint, clean the coils with a vacuum

cleaner, using the soft brush attachment. Be careful not to bend the

fins.Ifcoatedwith oilorgrease,cleanthecoilswithamilddetergent

andwatersolution.Rinsecoilswithclearwater ,usingagardenhose.

Be careful not to splash water on motors, insulation, wiring, or air

filter(s). For best results, spray condenser coil fins from inside to

outsidetheunit.On unitswithan outerand innercondensercoil,be

sure to clean between the coils. Be sure to flush all dirt and debris

from the unit base.

Inspectthedrainpanandcondensatedrain linewheninspectingthe

coils. Clean the drain pan and condensate drain by removing all

foreign matter from the pan. Flush the pan and drain trough with

clearwater.Do not splash wateron the insulation, motor, wiring, or

airfilter(s). Ifthedraintrough isrestricted,clearitwith a“plumbers

snake” or similar probe device.

Step 4—Outdoor Fan

UNIT OPERATION HAZARD

Failure to follow this caution may result in damage to unit

components.

Keep the condenser fan free from all obstructions to ensure

proper cooling operation. Never place articles on top of the

unit.

CAUTION

!

1. Remove 6 screws holding outdoor grille and motor to top

cover.

2. Turn motor/grille assembly upside down on top cover to

expose fan blade.

3. Inspect the fan blades for cracks or bends.

4. If fan needsto be removed, loosensetscrew and s lide fan off

motor shaft.

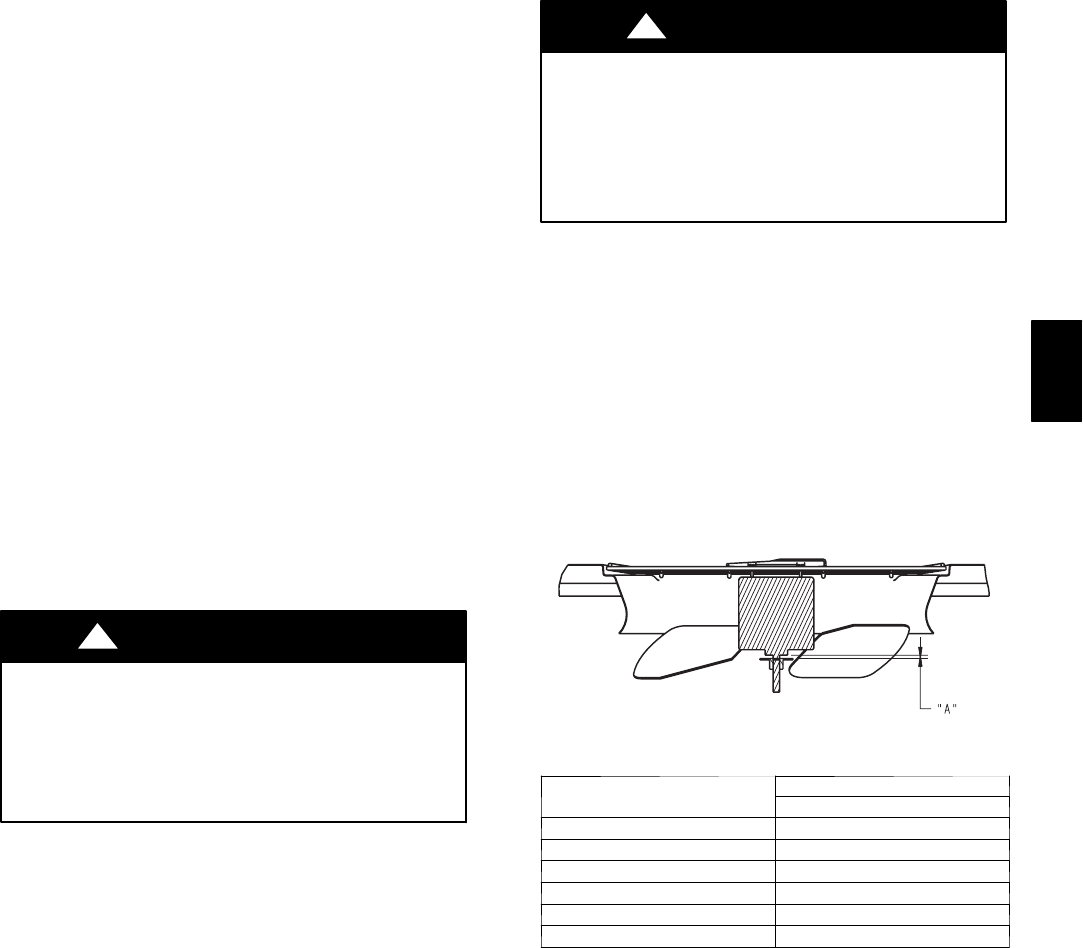

5. When replacing fan blade, position blade so that the hub is

1/8 in.away from the motorend (1/8 in. ofmotor shaft will

be visible) (See Fig. 24).

6. Ensurethatsetscrew engagestheflatareaonthemotorshaft

when tightening.

7. Replace grille.

Infinity Top

A06035

UNIT SIZE

“A” DIMENSION

Infinity

024 25

030 25

036 24

042 24

048 24

060 19

Fig. 24 -- Fan Blade Clearance

Step 5—Electrical Controls and Wiring

Inspect and check the electrical controls and wiring annually. Be

sure to turn off the electrical power to the unit.

Remove accesspanel tolocateall theelectrical controls and wiring.

Check all electrical connections for tightness. Tighten all screw

connections. If any smoky or burned connections are noticed,

disassembletheconnection,clean alltheparts,re--stripthewireend

and reassemble the connection properly and securely.

After inspecting the electrical controls and wiring, replace all the

panels. Start the unit, and observe at least one complete cooling

cycle to ensure proper operation. If discrepancies are observed in

operating cycle, or if a suspected malfunction has occurred, check

each electrical component with the proper electrical

instrumentation. Refer to the unit wiring label when making these

checks.

50CR