Step 15—Final Checks

IMPORTANT: Before leaving job, be sure to do the following:

1. Securely fasten all panels and covers.

2. Tighten service valve stem caps to 1/12-turn past finger tight.

3. Leave User’s Manual with owner. Explain system operation

and periodic maintenance requirements outlined in manual.

4. Fill out Dealer Installation Checklist and place in customer

file.

CARE AND MAINTENANCE

For continuing high performance and to minimize possible equip-

ment failure, periodic maintenance must be performed on this

equipment.

Frequency of maintenance may vary depending upon geographic

areas, such as coastal applications.

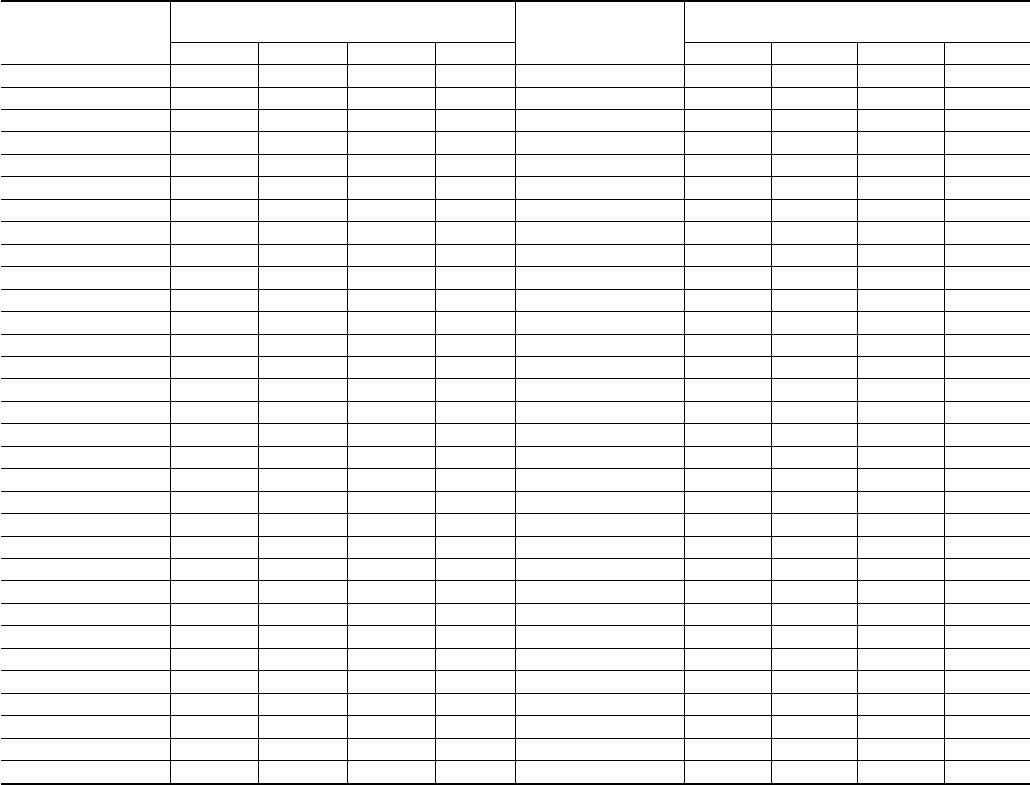

Table 4—Required Liquid-Line Temperature (°F)

LIQUID PRESSURE

AT SERVICE VALVE

REQUIRED SUBCOOLING TEMPERATURE

(°F)

LIQUID PRESSURE

AT SERVICE VALVE

REQUIRED SUBCOOLING TEMPERATURE

(°F)

5 10 15 20 5 10 15 20

174 56 51 46 41 398 112 107 102 97

181 58 53 48 43 405 113 108 103 98

188 61 56 51 46 412 114 109 104 99

195 63 58 53 48 419 115 110 105 100

202 65 60 55 50 426 117 112 107 102

209 67 62 57 52 433 118 113 108 103

216 69 64 59 54 440 119 114 109 104

223 71 66 61 56 447 120 115 110 105

230 73 68 63 58 454 122 117 112 107

237 75 70 65 60 461 123 118 113 108

244 77 72 67 62 468 124 119 114 109

251 79 74 69 64 475 125 120 115 110

258 81 76 71 66 482 126 121 116 111

265 82 77 72 67 489 127 122 117 112

272 84 79 74 69 496 129 124 119 114

279 86 81 76 71 503 130 125 120 115

286 88 83 78 73 510 131 126 121 116

293 89 84 79 74 517 132 127 122 117

300 91 86 81 76 524 133 128 123 118

307 93 88 83 78 531 134 129 124 119

314 94 89 84 79 538 135 130 125 120

321 96 91 86 81 545 136 131 126 121

328 97 92 87 82 552 137 132 127 122

335 99 94 89 84 559 138 133 128 123

342 100 95 90 85 566 139 134 129 124

349 102 97 92 87 573 140 135 130 125

356 103 98 93 88 580 141 136 131 126

363 105 100 95 90 587 142 137 132 127

370 106 101 96 91 594 143 138 133 128

377 107 102 97 92 601 144 139 134 129

384 109 104 99 94 608 145 140 135 130

391 110 105 100 95 — ————

15