22

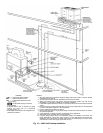

LIQUID LINE SOLENOID VALVE — Field-supplied

liquid line solenoid valve(s) must be installed at the evaporator

if coil surface area is exceeded per Table 8. Install liquid line

solenoid valve just ahead of the TXVs (thermostatic expansion

valves) which will be mounted at the evaporator. See Fig. 13

(for 38APD025-100 dual-circuit units), or Fig. 14 (for

38APS025-050 single-circuit units). Refer to Table 6.

THERMOSTATIC EXPANSION VALVES — All 38AP

units must be installed with 5% bleed TXVs to ensure proper

unit operation.

To achieve good mixing of the refrigerant leaving the evap-

orator suction header for proper sensing by the TXV bulb:

1. Install a minimum of two 90-degree elbows upstream

of the TXV bulb location. See Fig. 15 for dual-circuit

units and Fig. 16 for single-circuit units.

2. Locate the TXV bulb on a vertical riser, where possi-

ble. If a horizontal location is necessary, secure the

bulb at approximately the 4 o’clock position.

If an oil return connection is located at the bottom of the

evaporator suction header, tee-in this connection ahead of first

mixing elbow. See Fig. 15 (for dual-circuit units) or Fig. 16

(for single-circuit units). When the compressor is below the

evaporator, the riser at the evaporator should extend to the top

of the evaporator section. After the riser is installed, the suction

line can elbow down immediately. Refer to the evaporator

product data for sizing information.

LIQUID LINE FILTER DRIER — Installation of a field-

supplied filter drier and sight glasses in each refrigerant circuit

is required. Select the filter drier for maximum unit capacity

and minimum pressure drop. Figure 13 (for dual-circuit units)

or Fig. 14 (for single-circuit units) shows required location of

solenoid valves and recommended locations for the filter driers

and sight glasses. Complete the refrigerant piping from the

evaporator to the condenser before opening the liquid and suc-

tion lines at the condenser. Refer to Table 6.

LONG LINE APPLICATIONS — A long line option kit

must be installed for:

1. Any 025-030 size dual circuit unit where the evapora-

tor is located higher than the condensing unit and the

linear line length exceeds 55 ft (16.8 m).

2. Any size dual or single circuit unit with linear line

length of 100 ft (30.5 m) or more.

The kit consists of a liquid line check valve and a bypass

check valve to prevent charge migration to compressor. The

long line option kit must be mounted in the liquid line near the

condensing unit. The kit may be mounted in any orientation,

horizontally or vertically. See Fig. 17 for orientation and

Fig. 11 for location.

HOT GAS BYPASS — Hot gas bypass is not recommended.

If hot gas bypass is used, it should be introduced before the

evaporator.

FINAL CONNECTION AND LEAK TEST

Relieve the pressure caused by the nitrogen holding charge.

Connect liquid line and suction line to field piping. Refer to

Fig. 5-8 for circuit orientation.

The refrigerant system must not be opened and exposed to

atmosphere for longer than 15 minutes. Connection and pump-

down should be made as soon as possible to avoid acids

forming in the compressor POE (polyolester) oils, which could

damage the compressors.

Leak test the entire system by using soap bubbles and nitro-

gen or R-410A and an electronic leak detector.

Purge nitrogen or recover R-410A from system after com-

pletion of leak-checking procedure. Repair leak if one is found.

When finished, evacuate and dehydrate system using the fol-

lowing method.

EVACUATION AND DEHYDRATION — Because the

38AP systems use polyolester oil, which can absorb moisture,

it is important to minimize the amount of time that the system

interior is left exposed to the atmosphere. Minimizing the

exposure time of the oil to the atmosphere will minimize the

amount of moisture that needs to be removed during

evacuation.

Once all of the piping connections are complete, leak test

the unit and then pull a deep dehydration vacuum. Connect the

vacuum pump to the charging valve in the suction line and to

the liquid line service valve. For best results, it is recommended

that a vacuum of at least 500 microns (0.5 mm Hg) be ob-

tained. Afterwards, to ensure that no moisture is present in the

system, perform a standing vacuum-rise test.

With the unit in deep vacuum (500 microns or less), isolate

the vacuum pump from the system. Observe the rate-of-rise of

the vacuum in the system. If the vacuum rises by more than

50 microns in a 30-minute time period, then continue the dehy-

dration process. Maintain a vacuum on the system until the

standing vacuum requirement is met. This will ensure a dry

system.

By following these evacuation and dehydration procedures,

the amount of moisture present in the system will be mini-

mized. It is required that liquid line filter driers be installed be-

tween the condenser(s) and the expansion devices to capture

any foreign debris and provide additional moisture removal ca-

pacity. Be sure to consider the pressure drop of the filter drier

when determining piping requirements.

CAUTION

For all units with liquid lines of 100 ft (30.5 m) or more or

any 025-030 size dual circuit unit application where evapo-

rator is located higher than the condensing unit and liquid

lines exceed 55 feet (16.8 m), a long line option kit must be

installed to prevent compressor failure. The long line

option kit must be mounted in the liquid line near the con-

densing unit. See Fig. 17.

CAUTION

The 38AP unit is shipped with a nitrogen holding charge.

Use caution when relieving unit pressure to avoid possible

equipment damage or personal injury.

IMPORTANT: Protect the liquid and suction service

valves from the heat of brazing. Schrader valve cores

must be removed from the liquid and suction service

valves before brazing in field connection piping to avoid

damage. Reinsert cores after brazing is completed.