2

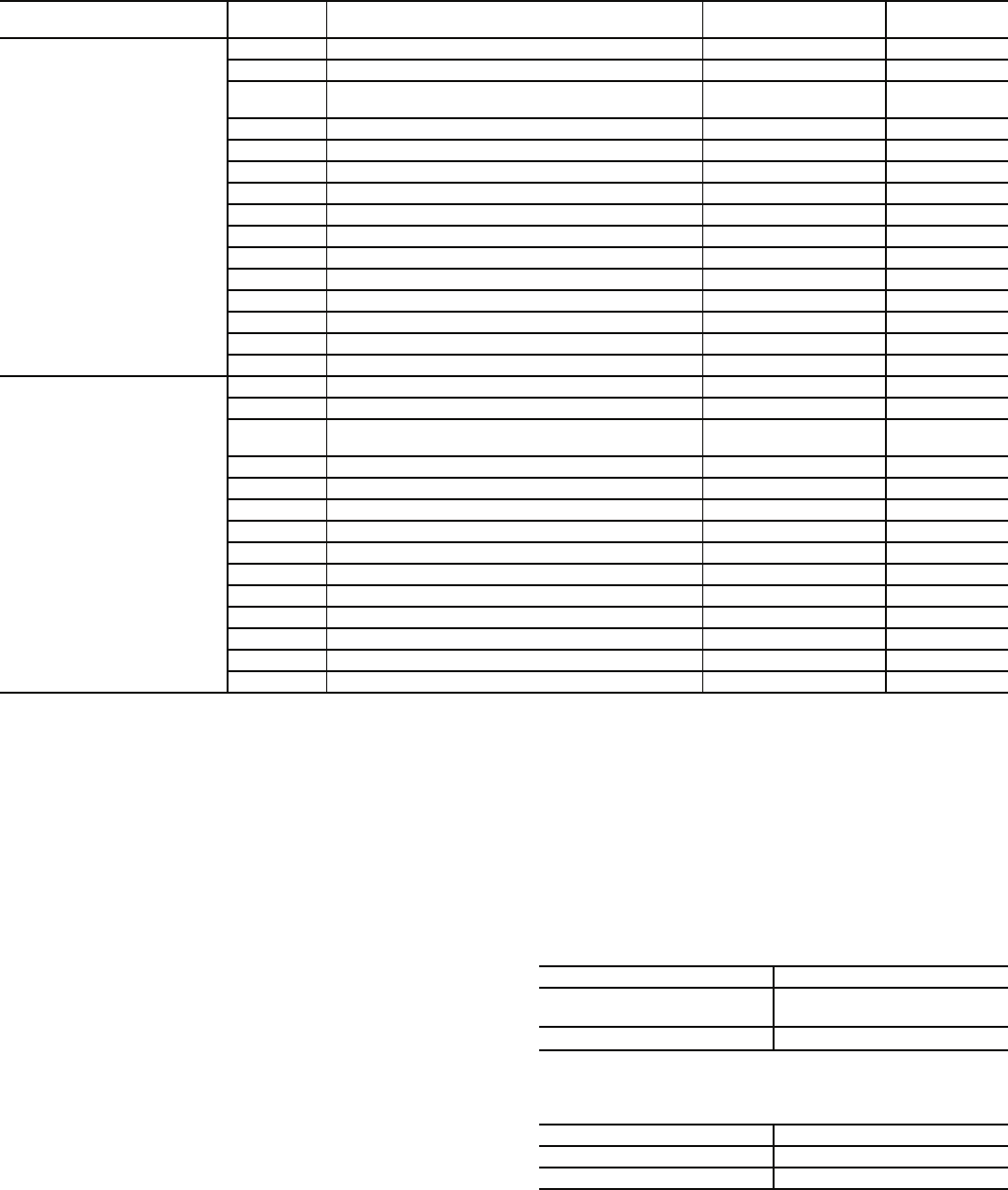

Table 2 — Accessory Package Contents

Choose a space that can support the weight of the cooler and

economizer with service clearances and area for refrigerant

piping. Field-supplied piping must be limited to less than

50 lineal ft (15.25 m) or 75 equivalent ft (22 m) in length.

Suction and liquid line risers must be limited to less than 15 ft

(4.5 m) vertical riser elevation. Suction lines and economizer

lines must be insulated to prevent condensation. Relocating the

cooler introduces minimal line losses if correct piping practices

are followed. Buried lines are not permitted.

The remote cooler system can be applied in three different

configurations. See Fig. 1-3. In Fig. 1, the remote cooler and

the outdoor unit are at the same elevation. The suction, liquid,

and economizer lines run parallel between the cooler and the

outdoor unit. In Fig. 2, the outdoor unit and remote cooler are

at the same elevation, but the interconnecting piping has an ele-

vation of up to 15 ft (4.5 m) above the base elevation of the

cooler. This could be result of running piping over a wall or

through the ceiling in a building. In Fig. 3, the remote cooler is

located below the outdoor unit. The interconnecting piping has

an elevation of up to 15 ft (4.5 m) above the base elevation of

the remote cooler. This could occur if the remote cooler is in-

stalled in a basement.

NOTE: Unit 30XA refrigeration piping can be either copper

tubing or steel tubing with flanged connections. All units are

factory charged with compressor oil to the required level.

However, when the double riser is constructed with U-bends or

street elbows, a substantial amount of oil can be trapped in the

U-bend during prolonged minimum load operation. If this

occurs, additional oil is needed to add to the system to prevent

the oil level from dropping below the minimum level in the oil

separator. Add 1 gallon of oil to each circuit. Refer to Controls,

Start-up, Operation, Service, and Troubleshooting Guide for

recommended oil type.

Table 3A — Refrigeration Piping and

Connections Material (English)

Table 3B — Refrigeration Piping and

Connections Material (SI)

ACCESSORY PACKAGE

PART NO.

ITEM NO. DESCRIPTION PART NO. QTY

00EFN900003000A

1 Economizer shutoff valve - 1

1

/

8

in. (29 mm) 00PPG000023501A 2

2 Liquid line shutoff valve - 1

3

/

8

in. (35 mm) EP71BA393 2

3 5 Wire jacketed cable RM02EJ200

200 ft

(61 m)

4 Cable assembly 32GB404694 5

5 Junction box HX30FZ001 2

6 Junction box cover HX38ZZ001 2

7 M6 Screws 00PPN500000302A 8

8 Cooler pipe flange - 3

1

/

8

in. (79 mm) 00PSN500091400A 2

10 Flex connector flange - 4 in. (102 mm) 00PSG000213300A 2

11 Loose pipe flange - 4 in. (102 mm) 00PSG000205100A 2

12 Cooler flange O-ring KK71EW256 4

13 Flex connector flange O-ring KK71EW250 2

14 Compressor flange gasket - 3 in. (76 mm) 00PPG000011702A 2

15 Compressor flange gasket - 4 in. (102 mm) 00PSG000011703A 4

16 Transducer wiring harness - 100 ft (30.5 m) 00PSN500180500A 2

00EFN900003100A

1 Economizer shutoff valve - 1

1

/

8

in. (29 mm) 00PPG000023501A 2

2 Liquid line shutoff valve - 1

3

/

8

in. (35 mm) EP71BA393 2

3 5 Wire jacketed cable RM02EJ200

200 ft

(61 m)

4 Cable assembly 32GB404694 5

5 Junction box HX30FZ001 2

6 Junction box cover HX38ZZ001 2

7 M6 Screws 00PPN500000302A 8

8 Flex connector flange O-ring KK1EW250 2

9 Compressor flange gasket - 4 in. (102 mm) 00PSG000011703A 4

10 Compressor flange gasket - 5 in. (127 mm) 00PPG000011704A 4

11 Loose pipe flange - 5 in. (127 mm) 00PSG000211900A 2

12 Loose pipe flange - 4 in. (102 mm) 00PSG000205100A 2

13 Flex connector flange - 4 in. (102 mm) 00PSG000213300A 2

14 Transducer wire harness - 100 ft (30.5 m) 00PSN500180500A 2

PIPE SIZE (in.) MATERIAL

5

/

8

,

7

/

8

, 1

1

/

8

, 1

3

/

8

, 1

5

/

8

,

2

1

/

8

, 2

5

/

8

, 3

1

/

8

Refrigeration copper

2, 2

1

/

2

, 3, 3

1

/

2

, 4 Schedule 40 Steel

PIPE SIZE (mm) MATERIAL

16, 22, 29, 35, 41, 54, 67, 79 Refrigeration copper

51, 64, 76, 89, 102 Schedule 40 Steel