16

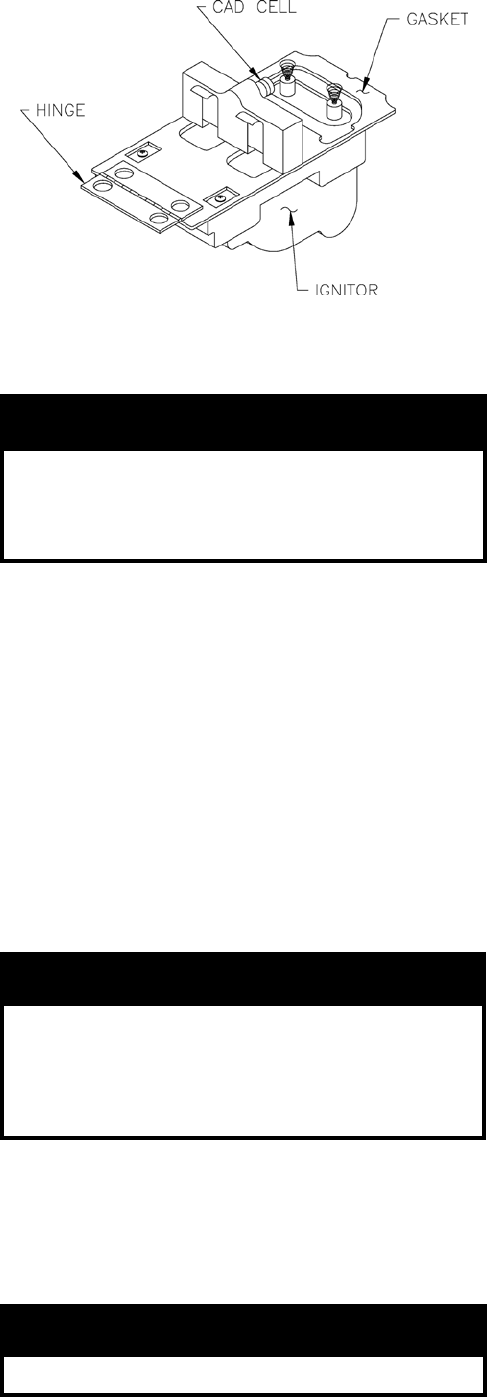

Figure 16: Cad Cell

Before pressing the reset button call your service-

man immediately.

NOITUAC

nehwrenrubehttratsottpmettatonoD

tinuehtnehw,detalumuccasahliossecxe

noitsubmocehtnehwro,ropavfollufsi

.tohyrevsirebmahc

11. CHECK FOR CLEAN CUT OFF OF BURNER

A. AIR IN THE OIL LINE between fuel unit and

nozzle will compress when burner is on and will

expand when burner stops, causing oil to squirt

from nozzle at low pressure as burner slows down

and causing nozzle to drip after burner stops.

Usually cycling the burner operation about 5 to 10

times will rid oil line of this air.

B. IF NOZZLE CONTINUES TO DRIP, repeat step

(11A). If this does not stop the dripping, remove

cutoff valve and seat, and wipe both with a clean

cloth until clean, then replace and re-adjust oil

pressure.

12. TEST CONTROLS.

GNINRAW

sireliobehtfonoitallatsnierofeB

ehtfonoitarepoeht,etelpmocderedisnoc

,dekcehcebdluohsslortnocreliob

hgihdnalortnocyramirpehtylralucitrap

.lortnoctimil

A. CHECK THERMOSTAT OPERATION. Raise and

lower thermostat setting as required to start and

stop burner.

B. VERIFY PRIMARY CONTROL SAFETY FEA-

TURES using procedures outlined in instructions

furnished with control or instructions below:

NOITUAC

YLNONAMECIVRESGNITAEHROF

(1) Safe Start

i. Jumper the yellow cad cell leads.

ii. Follow procedure to turn on burner.

Burner must not start, indictor light turns

on and control remains in Idle Mode.

(2) Simulate Flame Failure.

i. Follow procedure to turn on burner.

ii. Close hand valve in oil supply line.

iii. Device enters recycle mode.

iv. Device tries to restart system after

approximately 60 seconds.

v. Safety switch locks out approximately in

safety switch timing indicated on label.

Indicator light ashes at 1 Hz rate.

Ignition and motor stop and oil valve

closes.

(3) Simulate Ignition Failure.

i. Follow procedure to turn on burner, but do

not open oil supply hand valve.

ii. Observe that safety switch locks out

approximately within safety switch timing

as indicated on the label. Indicator light

ashes at 1 Hz rate. Ignition and motor

stop and oil valve closes.

(4) The indicator light on the oil primary control

provides lockout, recycle and cad cell indica-

tions as follows:

i. Flashing at 1 Hz (½ second on, ½ second

off): system is locked out or in restricted

mode.

ii. Flashing at ¼ Hz (2 seconds on, 2 seconds

off): control is in recycle mode.

iii. On: cad cell is sensing ame.

iv. Off: cad cell is not sensing ame.

C. CHECK HIGH LIMIT CONTROL. Jumper

thermostat terminals. Allow burner to operate until

shut-down by limit. Installation is not considered

complete until this check has been made.

REMOVE JUMPER.

IF CONTROLS DO NOT MEET REQUIREMENTS

OUTLINED IN PARAGRAPH 12, REPLACE

CONTROL AND REPEAT CHECK-OUT

PROCEDURES.

13. BOILER AND SYSTEM CLEANING INSTRUC-

TIONS FOR TROUBLE FREE OPERATION

A. Filling of Boiler and System — General —-In a hot

water heating system, the boiler and entire system

(other than the expansion tank) must be full of

water for satisfactory operation. Water should be

added to the system until the boiler pressure gauge

registers 12 psi. To insure that the system is full,

water should come out of all air vents when

opened. The LE boiler holds 6.1 gallons of water.