27

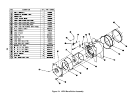

2. Remove and clean the pump strainer (if applicable).

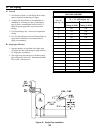

3. Replace the nozzle with an equivalent nozzle. See

Table 4.

4. Clean and inspect the electrodes for damage,

replacing any that are cracked or chipped.

5. Clean the combustion head of all lint and soot.

6. Inspect the transformer cables and connectors.

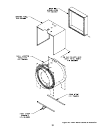

7. Remove and clean the cad cell.

8. Clean the blower wheel and the air control of any

lint.

9. Check all wiring for secure connections or

insulation breaks.

10.Re-adjust the burner as detailed in Section VII:

System Start-up, Paragraph F.

E. Controls. Test Controls for proper operation as

detailed in Section VII: System Start-up, Paragraph G.

F. Low water cutoff (if so equipped).

1. Float Type

a. Monthly Blowoff. During the heating season, if

an external float type low water cutoff is on the

boiler, the blow off valve should be opened once

a month (use greater frequency where conditions

warrant), to flush out the sediment chamber so

the device will be free to function properly.

b. Annual Service. Float type low water cutoffs

should be dismantled annually by qualified

personnel, to the extent necessary to insure

freedom from obstructions and proper

functioning of the working parts. Inspect

connecting lines to boiler for accumulation of

mud, scale, etc., and clean as required.

Examine all visible wiring for brittle or worn

insulation and make sure electrical contacts are

clean and that they function properly. Give

special attention to solder joints on bellows and

float when this type of control is used. Check

float for evidence of collapse and check mercury

bulb (where applicable) for mercury separation

or discoloration.

2. Probe Type (Annual Service). Probe type LWCO

should be removed once a year, examined and

cleaned of any dirt accumulations to assure proper

operations. Do not attempt to repair mechanisms in

the field. Complete replacement mechanisms,

including necessary gaskets and installation

instructions, are available from the manufacturer.