4. Using penetrating oil, generously lubricate the four (4) bolt threads holding the catalyst housing in place.

Allow to penetrate.

5. Using a 9/16” wrench or 9/16” socket, loosen the four (4) bolts and remove the catalyst housing (drop down)

and place in a suitable work area.

6. Using needle nose pliers, grasp the front edge of the stainless steel “can” which houses a catalytic element and

pull upward.

7. Using a small putty knife or scraper, remove any gasket that may have adhered to the catalyst housing.

8. Now, obtain the new catalysts and wrap the stainless steel “can” with interam gasket and tape ends together

using scotch tape or masking tape.

9. Insert the new catalysts into the catalytic housing and push down until they are seated on the top of the

stainless steel wire mesh supports.

10. Reinstall the catalyst housing into the stove and secure in place with the bolts.

11. The stove is now ready for use.

DOOR GASKET REPLACEMENT (Cold Heater)

To replace deteriorated gaskets, the following steps must be taken to ensure proper installation of gaskets.

1. Obtain the proper gaskets and silicone glue from your local dealer.

2. Using pliers, remove any worn and deteriorated gaskets.

3. Using a scraper, wire brush, and sandpaper or steel wool, clean glue and gasket residue from the door frame.

4. Measure and cut gaskets to length. Care should be taken not to stretch the gaskets. What you want is a full and

loose gasket weave after attachment to the framing.

5. Obtain the silicone glue and run a 3/16” bead inside the door frame.

6. Obtain the gasket (s) and place in the gasket channel areas. Use a technique which assures that the gasket is

applied in a loose like manner. DO NOT STRETCH GASKETS.

7. After gasket (s) are applied to the glue, use your finger and go over all the gasket gently pressing the gasket to

the channel. Use the same pressure against the gasket so that the final result is an evenly applied gasket.

8. Leave door open and allow at least one hour for the glue to dry.

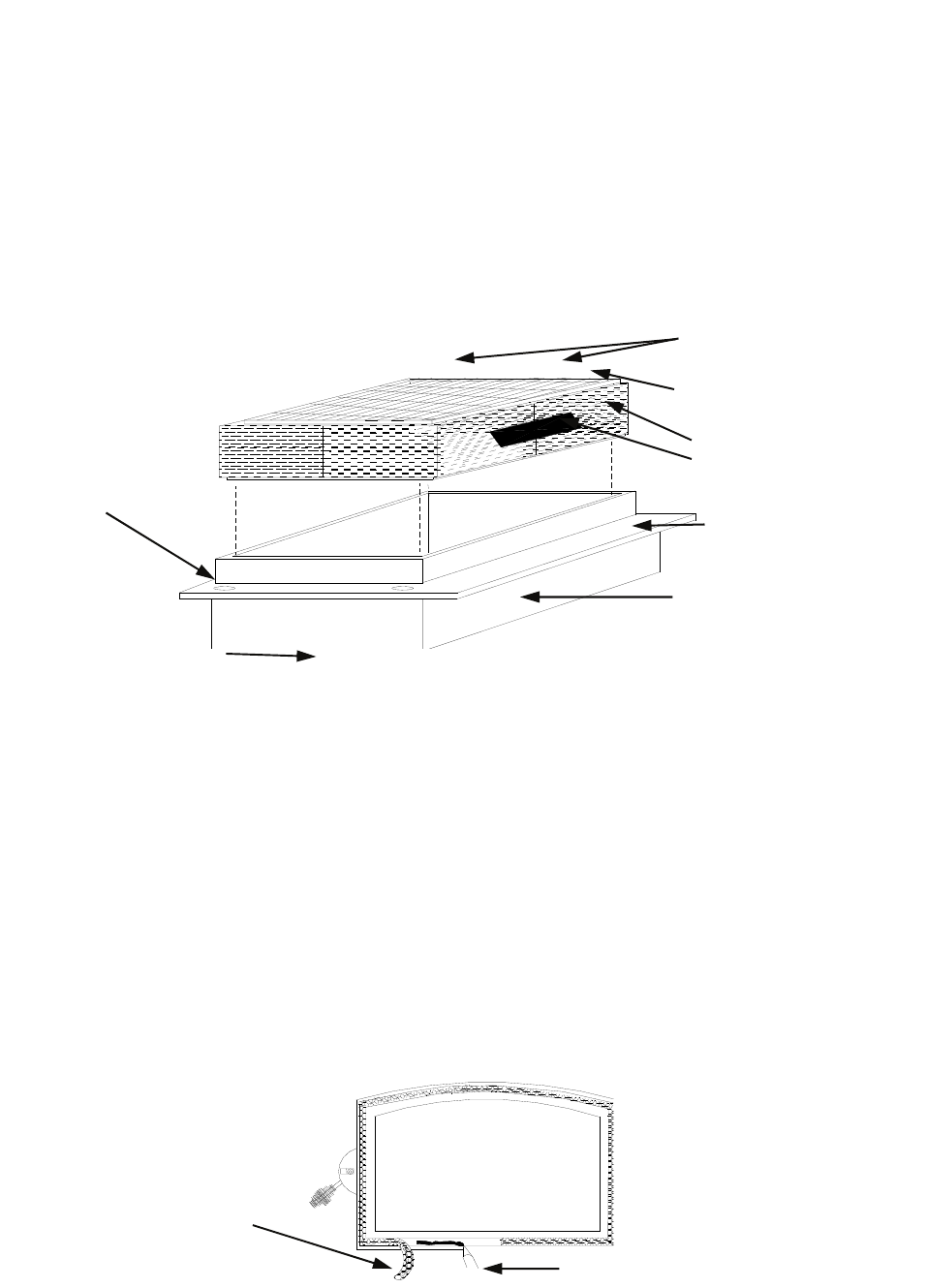

ROPE GASKET

SILICONE

2” X 2” X 7” STANDARD 25 CELL

CORNING LONG LIFE CATALYSTS

1/16” THICK INTERAM GASKET AND

STAINLESS STEEL CAN (2 EA.)

1/16” THICK INTERAM GASKET

(LAP ENDS 1/4” AND TAPE)

APPLY 1/16”X 1/2” FIBERGLASS

GASKET COMPLETELY AROUND

SEALING LIP.

CATALYST HOUSING

(STEEL OR CAST IRON)

FRONT

BOLT HOLES