VIII. INSTALL ELECTRICAL ACCESSORIES

A. GENERAL

Refer to the individual instructions packaged with kits or acces-

sories when installing.

Available electrical accessories include latent capacity control. See

Fig. 11 for typical accessory wiring diagrams.

B. LATENT CAPACITY CONTROL (LCC)

The purpose of an LCC is to provide a dehumidification mode to

assure a 75 percent or less system sensible heat ratio. If indoor unit

installed contains an ECM blower (such as an FK4C or FV4A fan

coil or a 315(A,J)AV or 355MAV gas furnace), no LCC is

required. Indoor products with ECM blowers have enough CFM

range to provide proper airflow for low-speed cooling. If indoor

unit installed has a standard PSC blower motor, the low-speed

airflow available is too great to assure 75 percent or less system

sensible heat ratio. The LCC for standard blower products consists

of a standard humidistat which opens contacts on humidity rise and

a pilot duty relay with 24v coil.

NOTE: If an LCC is desired, low-speed airflow must be main-

tained so that a minimum of 300 CFM/ton can be supplied during

high-speed LCC operation.

LCC OPERATION FOR TYPICAL PSC FAN COILS

The standard blower operation for systems with typical PSC fan

coils is covered in Fig. 11. The blower runs in high speed

regardless if compressor operation is high or low speed. When the

LCC is wired according to Fig. 11 and humidity rises, the

humidistat contacts open and de-energize the relay. If relay is

de-energized, the system operates on high-speed compressor and

high-speed airflow until humidistat closes. Fig. 11 shows the

wiring with a Bryant Thermidistat which controls temperature and

humidity level without the need for an additional humidistat and

relay.

LCC OPERATION FOR TYPICAL PSC FURNACES

The standard blower operation of systems with typical PSC

furnaces is covered in Fig. 11. The blower runs in high or low

speed in conjunction with compressor high- or low-speed opera-

tion. When the LCC is wired according to Fig. 11, humidity rises,

the humidistat contacts open and de-energize the relay. If relay is

de-energized, the system operates on high-speed compressor and

low-speed airflow until humidistat closes. Fig. 11 shows the wiring

with a Bryant Thermidistat which controls temperature and hu-

midity level without the need for an additional humidistat and

relay.

IX. MAKE AIRFLOW SELECTIONS

A. AIRFLOW SELECTION FOR 315AAV/355MAV FUR-

NACES

The 315AAV/355MAV Non-Condensing Variable Speed Fur-

naces provide high- and low-speed blower operation to match the

capacities of the compressor at high and low speeds. To select the

recommended airflow and for adjustments to the manual switches

labeled SW1, A/C and CF on the control board refer to the furnace

Installation, Start-Up, and Operating Instructions. The 315AAV

utilizes a control center that allows the installing technician to

select the proper airflows. The A/C switch determines the airflow

during high speed compressor operation. Airflow for hight and low

speed can be calculated at either 350 CFM per ton or 400 CFM per

ton based on the positions of SW1-5.

B. AIRFLOW SELECTION FOR FK4C OR FV4A FAN

COILS

The FK4C and FV4A provides high- and low-speed blower

operation to match the capacities of compressor at high and low

speeds. To select recommended airflow, refer to the FK4C or

FV4A Installation Instructions. The FK4C and FV4A utilize an

EASY SELECT control board that allows the installing technician

to select proper airflows. For adjustments to control board and

recommended A/C SIZE and CFM ADJUST selections, refer to

the fan coil Installation Instructions. This fan coil has an adjustable

blower off delay factory set at 90 sec. for high- and low-speed

blower operation.

TABLE 2—ACCESSORY USAGE

ACCESSORY

REQUIRED FOR

LONG-LINE

APPLICATIONS

*

(50-175 FT)

REQUIRED FOR

SEACOAST

APPLICATIONS

(WITHIN 2 MILES)

Coastal Filter No Yes

Support Feet No Recommended

Puron® Balance-Port Hard Shutoff TXV Yes† Yes†

* For tubing line sets between 50 and 175 ft horizontal or 20 ft vertical differential refer to Service Manual for Air Conditioners and Heat Pumps Using Puron® Refrigerant.

Crankcase heater and start assist are standard on two-speed units.

† All two-speed units require hard shut-off TXV.

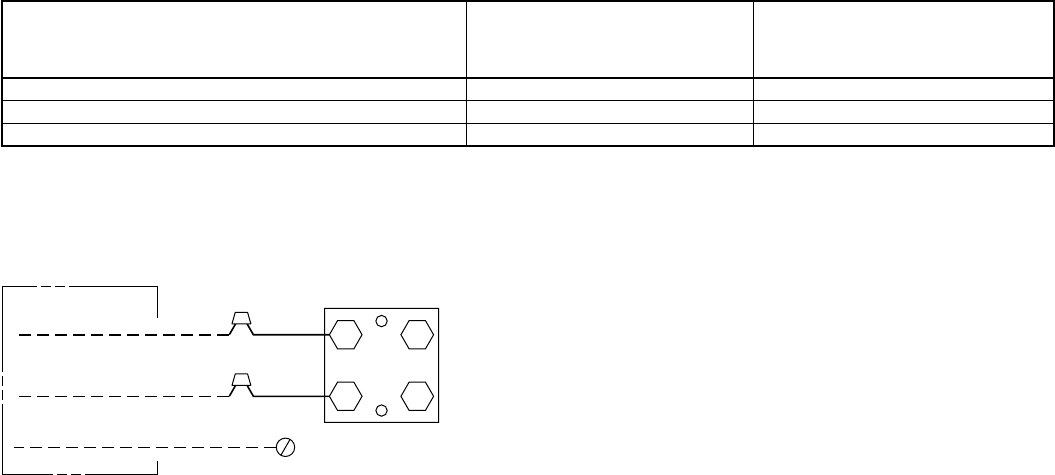

Fig. 10—Line Power Connections

A91306

CONTACTOR

DISCONNECT

PER N. E. C. AND/ OR

LOCAL CODES

FIELD POWER

WIRING

FIELD GROUND

WIRING

GROUND

LUG

—6—