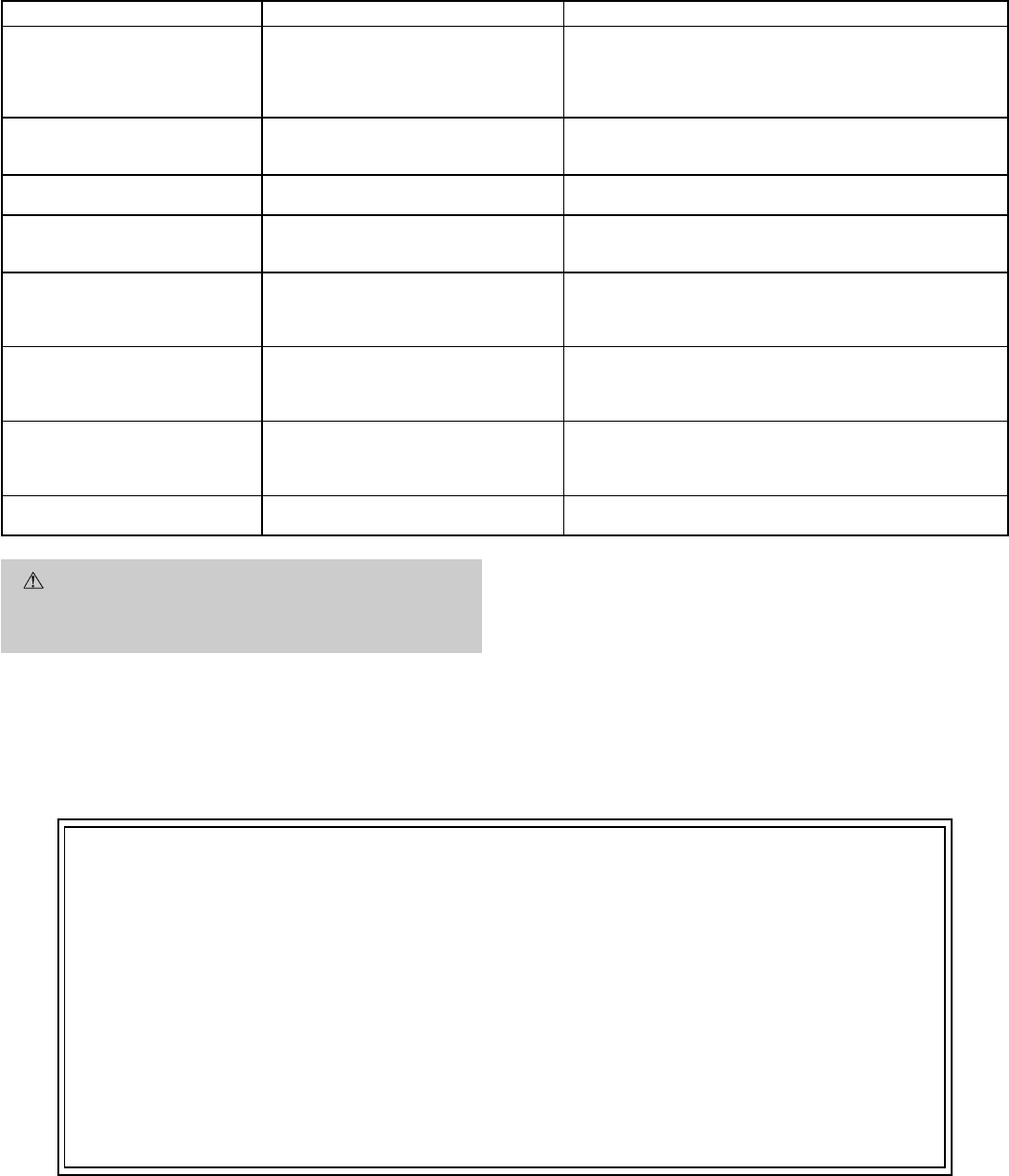

LED Troubleshooting — Error Code

SYMPTOM CAUSE REMEDY

Hardware failure.

(LED OFF)

Loss of power to control module

(IGC).

Check 5 amp fuse on IGC, power to unit, 24-v circuit

breaker, and transformer. Units without a 24-v circuit

breaker have an internal overload in the 24-v trans-

former. If the overload trips, allow 10 minutes for au-

tomatic reset.

Limit switch fault.

(LED 2 flashes)

High temperature limit switch is

open.

Check the operation of the indoor (evaporator) fan

motor. Ensure that the supply-air temperature rise is

in accordance with the range on the unit nameplate.

Flame sense fault.

(LED 3 flashes)

The IGC sensed flame that

should not be present.

Reset unit. If problem persists, replace control board.

4 consecutive limit switch

faults.

(LED 4 flashes)

Inadequate airflow to unit. Check operation of indoor (evaporator) fan motor and

that supply-air temperature rise agrees with range on

unit nameplate information.

Ignition lockout.

(LED 5 flashes)

Unit unsuccessfully attempted

ignition for 15 minutes.

Check ignitor and flame sensor electrode spacing,

gaps, etc. Ensure that flame sense and ignition wires

are properly terminated. Verify that unit is obtaining

proper amount of gas.

Induced-draft motor fault.

(LED 6 flashes)

IGC does not sense that induced-

draft motor is operating.

Check for proper voltage. If motor is operating, check

the speed sensor plug/IGC Terminal J2 connection.

Proper connection: PIN 1 — White, PIN 2 — Red,

PIN 3 — Black.

Rollout switch fault.

(LED 7 flashes)

Rollout switch has opened. Rollout switch will automatically reset, but IGC will

continue to lockout unit. Check gas valve operation.

Ensure that induced-draft blower wheel is properly

secured to motor shaft. Reset unit at unit disconnect.

Internal control fault.

(LED 8 flashes)

Microprocessor has sensed an

error in the software or hardware.

If error code is not cleared by resetting unit power,

replace the IGC.

WARNING:

If the IGC must be replaced, be sure to ground

yourself to dissipate any electrical charge that may be present

before handling new control board. The IGC is sensitive to static

electricity and may be damaged if the necessary precautions are

not taken.

IMPORTANT: Refer to Heating troubleshooting chart for additional

troubleshooting analysis.

LEGEND

IGC — Integrated Gas Unit Controller

LED — Light-Emitting Diode

SERVICE TRAINING

Packaged Service Training programs are an excellent way to increase your knowledge of the equip-

ment discussed in this manual, including:

• Unit Familiarization

• Installation Overview

• Maintenance

• Operating Sequence

A large selection of product, theory, and skills programs are available, using popular video-based

formats and materials. All include video and/or slides, plus companion book.

Classroom Service Training which includes ‘‘hands-on’’ experience with the products in our labs

that can mean increased confidence that really pays dividends in faster troubleshooting and fewer

callbacks. Course descriptions and schedules are in our catalog.

CALL FOR FREE CATALOG 1-800-962-9212

[ ] Packaged Service Training

[ ] Classroom Service Training

Copyright 1998 BryantHeating & Cooling Systems CATALOG NO.CATALOG NO. 5358-802