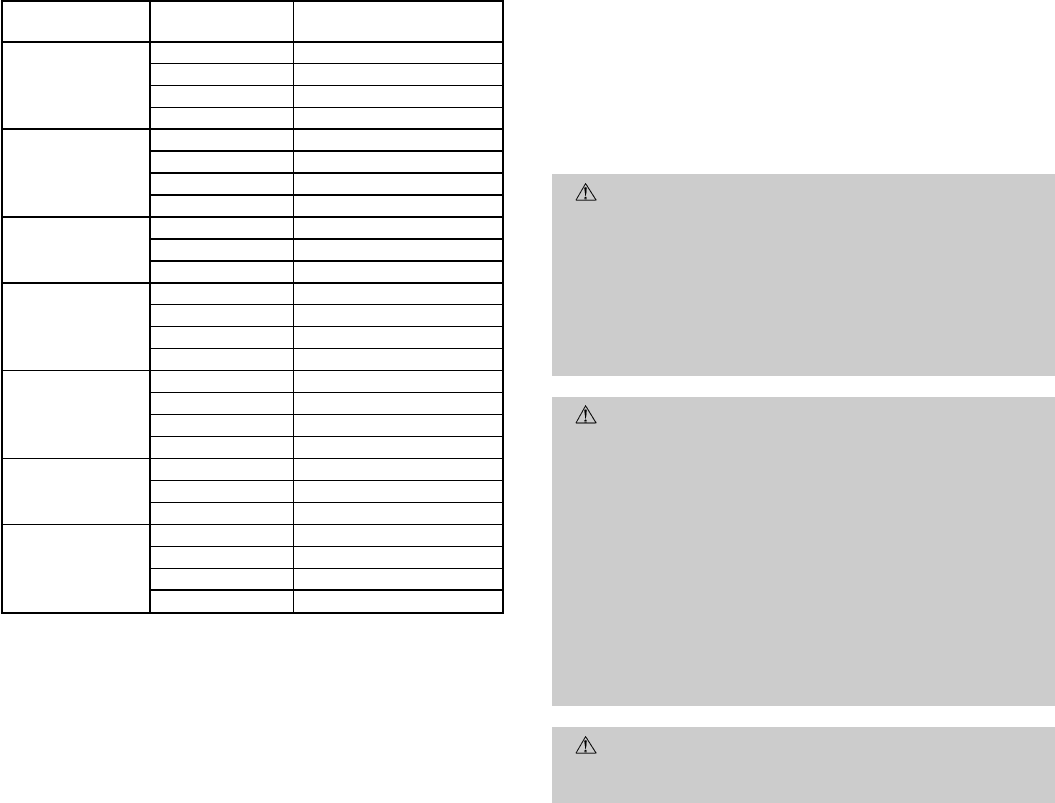

Table 17 — Wet Coil Pressure Drop

UNIT SIZE

AIRFLOW

(cfm)

PRESSURE DROP

(in. wg)

018*

600 0.069

700 0.082

800 0.102

900 0.116

024

600 0.039

700 0.058

800 0.075

900 0.088

030

900 0.088

1000 0.095

1200 0.123

036

1000 0.068

1200 0.088

1400 0.108

1600 0.123

042

1000 0.048

1200 0.069

1400 0.088

1600 0.102

048

1400 0.068

1600 0.075

1800 0.088

060

1700 0.082

1900 0.095

2100 0.108

2300 0.123

*Unit 588A only.

D. Cooling Sequence of Operation

With the room thermostat SYSTEM switch in the COOL po-

sition and the FAN switch in theAUTO. position, the cooling

sequence of operation is as follows:

When the room temperature rises to a point that is slightly

above the cooling control setting of the thermostat, the ther-

mostat completes the circuit between thermostat terminal R

to terminals Y and G. These completed circuits through the

thermostat connect contactor coil (C) (through unit wire Y)

and blower relay coil (BR) (through unit wire G) across the

24-v secondary of transformer (TRAN).

NOTE: The blower relay coil (BR) is used on standard non-

ICM units, ICM units use evaporator (indoor) fan on (IFO)

connection.

The normally-open contacts of energized contactor (C) close

and complete the circuit through compressor motor (COMP)

to condenser (outdoor) fan motor (OFM). Both motors start

instantly.

On standard non-ICM units, the set of normally-open con-

tacts of energized relay BR close and complete the circuit

through evaporator blower (indoor) fan motor (IFM). On ICM

units, the IFO completes the circuit through evaporator blower

IFM. The blower motor starts instantly.

NOTE: Once the compressor has startedand then has stopped,

it should not be started again until 5 minutes have elapsed.

The cooling cycle remains ‘‘on’’ until the room temperature

drops to point that is slightly below the cooling control set-

ting of the room thermostat. At this point, the thermostat

‘‘breaks’’ the circuit between thermostat terminal R to termi-

nals Y and G. These open circuits deenergize contactor coil C

and relay coil BR. The condenser and compressor motors stop.

After a 30-second delay, the blower motor stops. The unit is

in a ‘‘standby’’ condition, waiting for the next ‘‘call for cool-

ing’’ from the room thermostat.

MAINTENANCE

To ensure continuing high performance, and to minimize the

possibility of premature equipment failure, periodic mainte-

nance must be performed on this equipment. This combina-

tion heating/cooling unit should be inspected at least once each

year by a qualified service person. To troubleshoot heating or

cooling of units, refer to tables at the back of the book.

NOTE TO EQUIPMENT OWNER: Consult your local dealer

about the availability of a maintenance contract.

WARNING:

The ability to properly perform mainte-

nance on this equipment requires certain expertise, me-

chanical skills, tools, and equipment. If you do not pos-

sess these, do not attempt to perform any maintenance

on this equipment other than those procedures recom-

mended in the User’s Manual. FAILURE TO HEED THIS

WARNING COULD RESULT IN SERIOUS PERSONAL

INJURY AND POSSIBLE DAMAGE TO THIS

EQUIPMENT.

WARNING:

Failure to follow these warnings could re-

sult in serious personal injury:

1. Turn off gas supply, then turn off electrical power to

the unit before performing any maintenance or serv-

ice on the unit.

2. Use extreme caution when removing panels and parts.

As with any mechanical equipment, personal injury

can result from sharp edges, etc.

3. Never place anything combustible either on, or in con-

tact with, the unit.

4. Should overheating occur, or the gas supply fail to

shut off, shut off the external main manual gas valve

to the unit, then shut off the electrical supply.

CAUTION:

Errors made when reconnectingwires may

cause improper and dangerous operation. Label all wires

prior to disconnection when servicing.

The minimum maintenance requirements for this equipment

are as follows:

1. Inspect air filter(s) each month. Clean or replace when

necessary.

2. Inspect indoorcoil, drain pan,and condensate draineach

cooling season for cleanliness. Clean when necessary.

3. Inspect blower motor and wheel for cleanliness and check

lubrication each heating and cooling season. Clean and

lubricate (if required) when necessary. For first heating

season, inspect blower wheel bimonthly to determine

proper cleaning frequency.

4. Check electrical connections for tightness and controls

for proper operation each heating and cooling season.

Service when necessary.

5. Check and inspect heating section before each heating

season. Clean and adjust when necessary.

6. Check flue hood screen and remove any obstructions if

necessary.

7. Check vent screen and clean if necessary.

—44—