(Text continued from page 13)

CAUTION:

Unstable operation may occur when the

gas valve and manifold assembly are forced out of po-

sition while connecting improperly-routed rigid gas pip-

ing to the gas valve. Use a backup wrench when mak-

ing connection to avoid strain on, or distortion of, the

gas control piping.

CAUTION:

If a flexible conductor is required or al-

lowed by the authority having jurisdiction, black iron

pipe shall be installed at the gas valve and shall ex-

tend a minimum of 2 in. outside the unit casing.

WARNING:

Never use a match or other open flame

when checking for gas leaks. Never purge gas line into

combustion chamber. Failure to follow this warning could

result in an explosion causing personal injury or death.

8. Check for gas leaks at the field-installed and factory-

installed gas lines after all piping connections have been

completed. Use soap-and-water solution (or method speci-

fied by local codes and/or regulations).

IX. STEP 9 — INSTALL DUCT CONNECTIONS

The unit has duct flanges on the supply- and return-air open-

ings on the side and bottom of the unit. See Fig. 2-9 for con-

nection sizes and locations.

A. Configuring Units for Downflow (Vertical) Discharge

WARNING:

Before performing service or mainte-

nance operations on the system, turn off main power to

unit or electrical shock could result.

1. Open all electrical disconnects before starting any serv-

ice work.

2. Remove return duct cover located on duct panel.

Figure 16 shows duct cover removed. Save duct cover

and screws.

3. Locate lances in basepaninsulation that are placed over

the perimeter of the vertical duct opening cover

(Fig. 17).

4. Using a straight edge and sharp knife, cut and remove

the insulation around the perimeter of the cover. Re-

move and save 5 screws securing the cover to the base-

pan and slide out the cover. Discard the cover (Fig. 18).

5. Remove supply duct cover located on duct panel.

Figure 16 shows duct cover removed. Save duct cover

and screws.

6. Remove and discard 2 screws which secure vertical dis-

charge opening cover to basepan (Fig. 19). Slide cover

forward to disengage, then tilt and removecover through

vertical discharge opening in bottom of unit. Discard

duct cover (Fig. 20).

CAUTION:

Collect ALL screws that were removed.

Do not leave screws on rooftop as permanent damage

to the roof may occur.

7. If unit ductwork is to be attached to vertical opening

flanges on the unit basepan(jackstand applications only),

do so at this time.

8. It is recommended that the basepan insulation around

the perimeter of the vertical return-air opening be se-

cured to the basepan with aluminum tape. Applicable

local codes may require aluminum tape to prevent ex-

posed fiberglass.

9. Cover both horizontal duct openings with the duct cov-

ers from Steps 2 and 5. Make sure opening is air- and

watertight.

10. After completing unit conversion, perform all safety

checks and power up unit.

NOTE: The design and installation of the duct system must

be in accordance with the standards of the NFPA for instal-

lation of nonresidence-type air conditioning and ventilating

systems, NFPA 90A or residence-type, NFPA 90B; and/or lo-

cal codes and residence-type, NFPA 90B; and/or local codes

and ordinances.

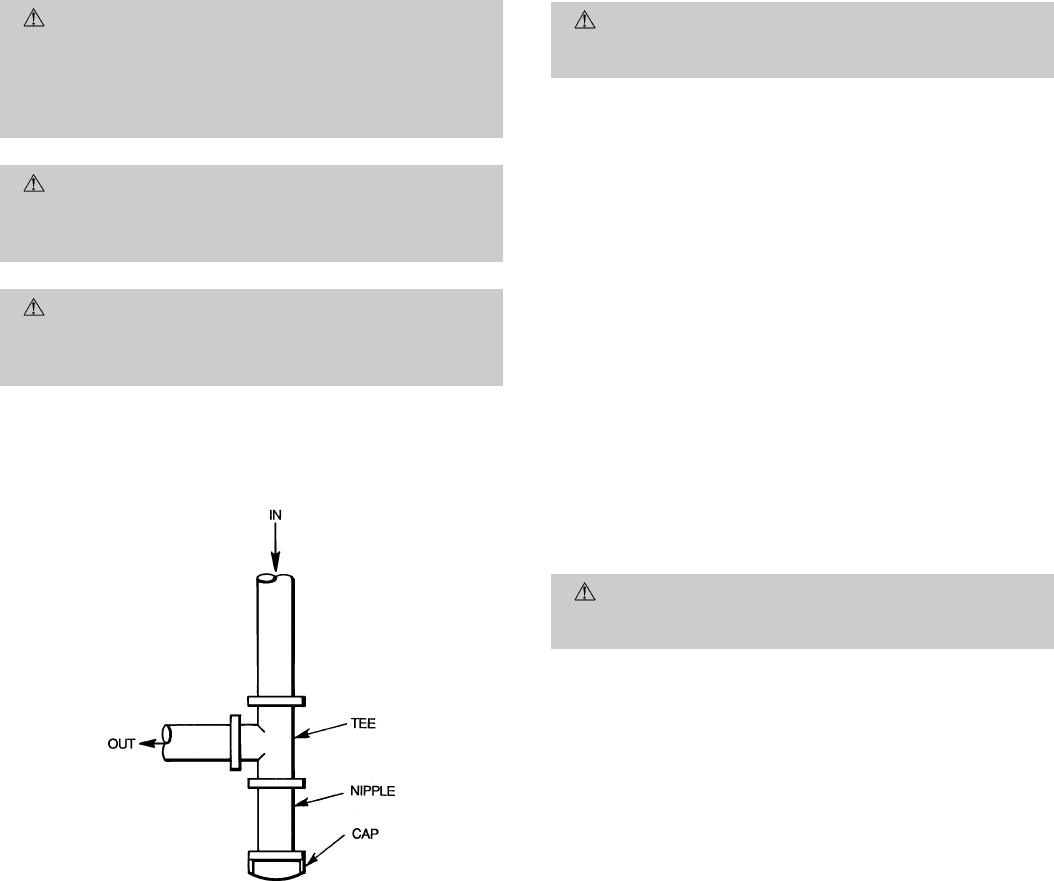

Fig. 15 — Sediment Trap

—16—