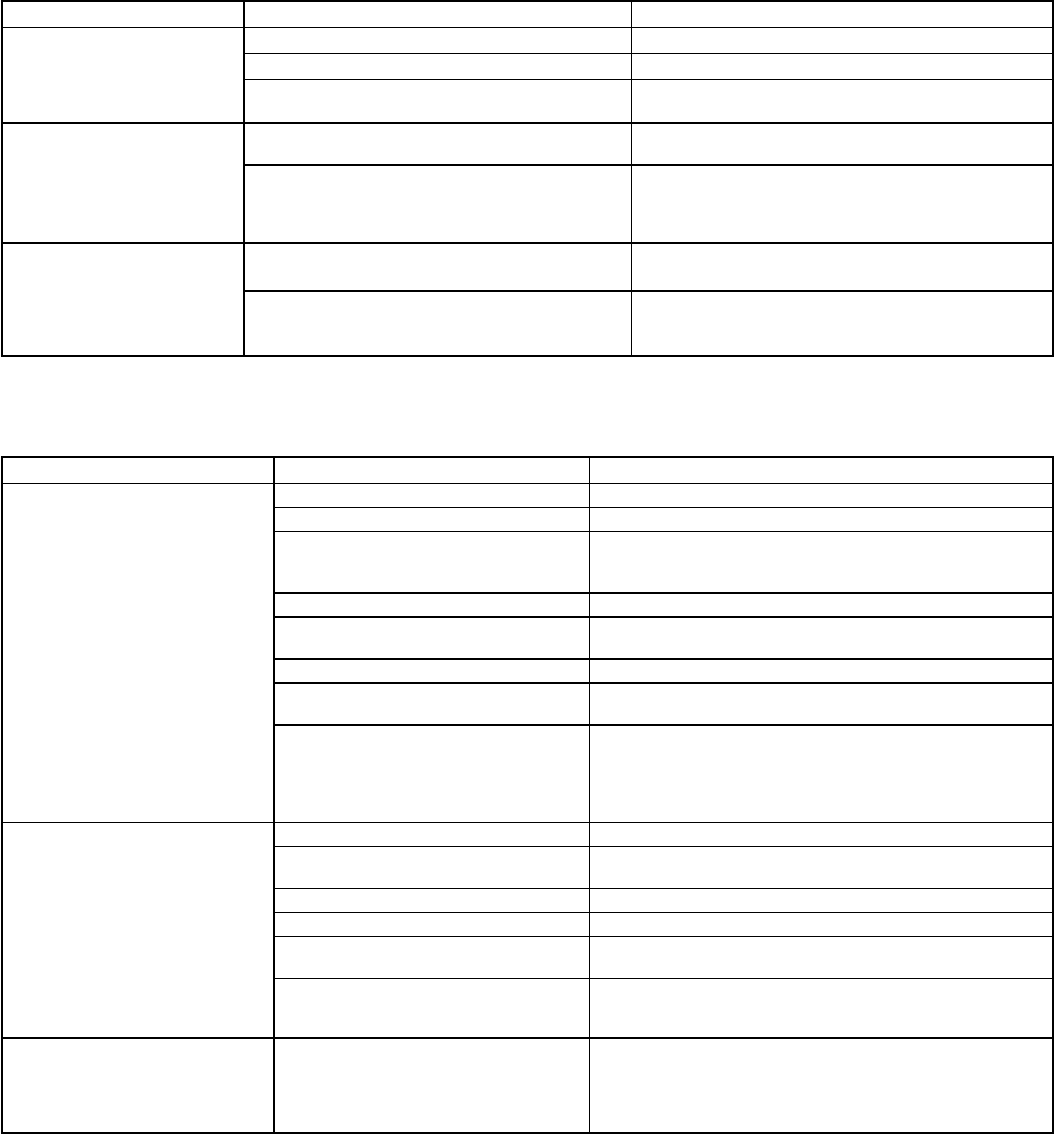

Cooling (cont)

SYMPTOM CAUSE REMEDY

Integrated control

motor

(units 589A048,060

208/230 v)

IFM does not run.

Blower wheel not secured to shaft Properly tighten blower wheel to shaft.

Insufficient voltage at motor Determine cause and correct.

Power connectors not properly

seated

Connectors should snap easily; do not

force.

Integrated control

motor (units

589A048,060

208/230 v)

IFM runs when it

should be off.

Motor programmed with a delay

profile

Allow a few minutes for motor to shut off.

With thermostat in OFF the voltage

on G,Y1,Y/Y2,W with respect to

common, should be

1

⁄

2

of actual

low voltage supply

If measured voltage is more than

1

⁄

2

, the

thermostat is incompatible with motor. If

voltage is less than

1

⁄

2

, the motor has failed.

Integrated control

motor (units

589A048,060

208/230 v) IFM

operation is

intermittent.

Water dripping into motor Verify proper drip loops in connector wires.

Connectors not firmly seated Gently pull wires individually to be sure they

are crimped into the housing.

IFM — Evaporator (Indoor) Fan Motor

Heating

SYMPTOM CAUSE REMEDY

Burners will not ignite. Water in gas line Drain. Install drip leg.

No power to furnace Check power supply fuses, wiring, or circuit breaker.

No 24-v power supply to control

circuit

Check transformer.

NOTE: Some transformers have internal overcurrent

protection that requires a cool-down period to reset.

Miswired or loose connections Check all wiring and wirenut connections.

Burned-out heat anticipator in

thermostat

Replace thermostat.

Broken thermostat wire Run continuity check. Replace wire if necessary.

Misaligned spark electrodes Check flame ignition and sense electrode positioning.

Adjust as necessary.

No gas at main burners 1. Check gas line for air. Purge as necessary.

NOTE: After purging gas line of air, wait at least

5 minutes for any gas to dissipate before attempt-

ing to light unit.

2. Check gas valve.

Inadequate heating. Dirty air filter Clean or replace filter as necessary.

Gas input to furnace too low Check gas pressure at manifold. Match with that on

unit nameplate.

Unit undersized for application Replace with proper unit or add additional unit.

Restricted airflow Clean or replace filter. Remove any restriction.

Blower speed too low Use faster speed tap if available, or install alternate

motor.

Limit switch cycles main burners Check rotation of blower, thermostat heat antic-

ipator settings, temperature rise of unit. Adjust as

necessary.

Poor flame characteristics. Incomplete combustion results in:

Aldehyde odors, carbon monox-

ide, sooting flame, floating flame

1. Tighten all screws around burner compartment.

2. Cracked heat exchanger. Replace.

3. Unit overfired. Reduce input (change orifices or

adjust gas line or manifold pressure).

4. Check burner alignment.

—49—