—21—

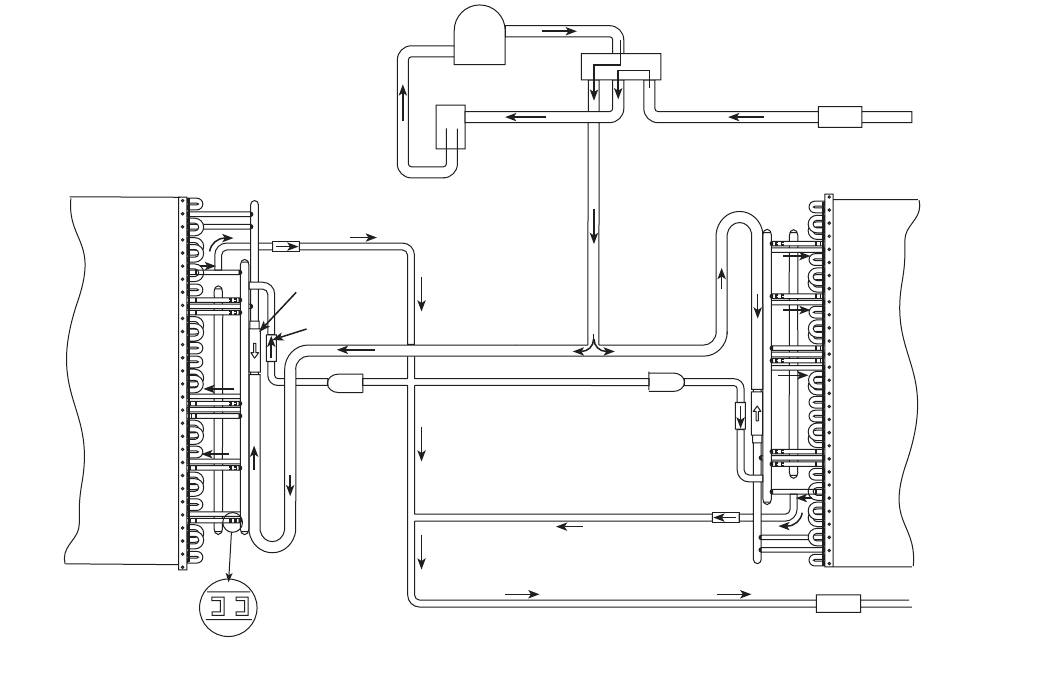

IV. 541A180 COOLING MODE OPERATION (See Fig. 22)

1. High pressure, high temperature refrigerant vapor

from the compressor flows through the reversing

valve and is directed to the outdoor coil vapor header.

2. At the outdoor coil vapor header, the high pressure,

high temperature refrigerant vapor flows up to check

valve “A” that blocks the flow. All the refrigerant is

then directed to flow into the coil circuits.

3. Subcooled refrigerant liquid leaves the coil circuits

entering the portion of the vapor header which is

above check valve “A”. Check valve “C” is closed,

therefore, the liquid refrigerant passes through check

valve “B,” which is open, and enters the liquid line

and goes to the indoor coil.

4. The liquid refrigerant is expanded and evaporated in

the indoor coil resulting in low pressure vapor. This

low pressure vapor returns to the outdoor unit

through the system vapor line, reversing valve, and

accumulator, reentering the compressor at the suc-

tion connection.

V. 541A180 HEATING MODE OPERATION (See Fig. 23)

1. High pressure, high temperature refrigerant vapor

from the compressor flows through the reversing

valve and is directed through the system vapor line

to the indoor coil. Refrigerant is condensed and

subcooled in the indoor coil and returns to the

outdoor unit through the system liquid line.

2. Check valve “B” blocks the flow of liquid and the

refrigerant is then directed to flow through check

valve “C” (which is open), through the filter drier, and

into the liquid header assembly.

3. The liquid refrigerant is expanded as it passes

through the capillary tubes into outdoor coil circuits.

The refrigerant evaporates as it passes through the

coil circuits resulting in low pressure vapor.

4. The low pressure vapor leaves the coil circuits and

enters the vapor header, check valve “A” is open, and

returns to the compressor through the vapor line,

reversing valve, and accumulator, reentering the

compressor at the suction connection.

VI. CRANKCASE HEATER

The crankcase heater prevents refrigerant migration and

compressor oil dilution during shutdown when compressor is

not operating.

Close both compressor service valves when crankcase heater

is deenergized for more than 6 hours.

VII. OUTDOOR UNIT FANS

Each fan is supported by a formed-wire mount bolted to the

fan deck and covered with a wire guard. On the 541A180, the

exposed end of the motor shaft is covered with a rubber boot.

In case a fan motor must be repaired or replaced, be sure the

rubber boot is put back on when the fan is reinstalled and be

sure the fan guard is in place before starting the unit.

VIII. LUBRICATION

Fan motors have permanently sealed bearings. No further

lubrication is required.

ACCUMULATOR

COMPRESSOR

REVERSING VALVE

VAPOR LINE

BALL

VALVE

FROM

INDOOR

UNIT

FILTER

DRIER

LIQUID LINE

BALL

VALVE

TO

INDOOR

UNIT

FIXED ORIFICE

METERING DEVICE

FILTER

DRIER

CK VALVE C

CK VALVE A

CK VALVE B

Fig. 20 — 575C090,120 Cooling Mode (Size 090 Shown)