5

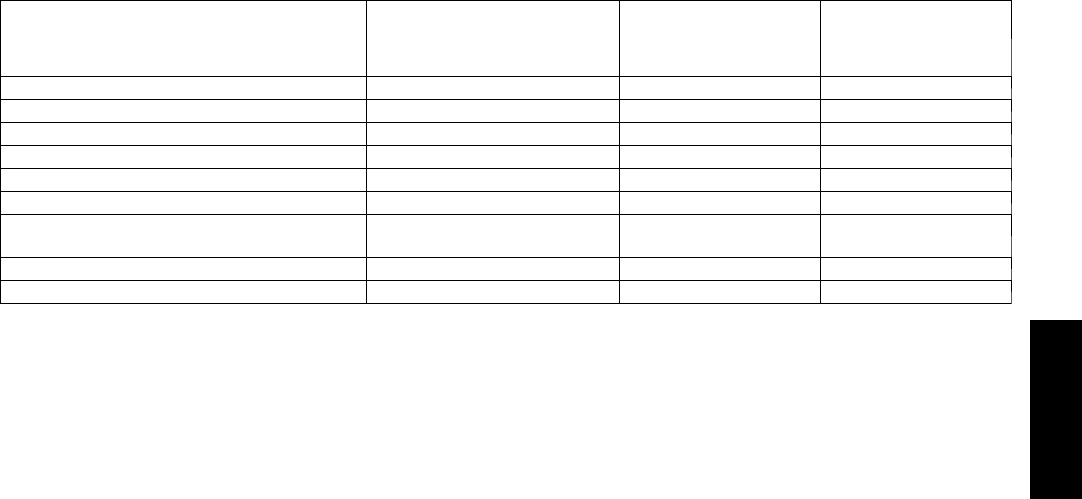

ACCESSORY USAGE GUIDELINE

ACCESSORY

REQUIRED FOR LOW---AMBI-

ENT COOLING APPLICATIONS

(Below 55°F/12.8_C)

REQUIRED FOR LONG

LINE

APPLICATIONS*

(Over 80 ft./24.38 m)

REQUIRED FOR

SEA COAST

APPLICATIONS

(Within2miles/3.22km)

Ball Bearing F an Motor Yes{ No No

Compressor Start Assist Capacitor and Relay Yes Yes No

Crankcase Heater Yes Yes No

Evaporator Freeze Thermostat Yes No No

H a r d Sh u t --- O f f T X V Yes Yes Yes

Liquid Line Solenoid Valve No No No

Motor Master

®

Control or

Lo w --- a m b ie n t Pr e s s u r e S wi tc h

Yes No No

Support Feet Recommended No Recommended

Winter Start Control Yes No No

* For tubing line sets between 80 and 200 ft. (24.38 an d 60.96 m) and/or 20 ft. (6.09 m) vertical differential, ref er to Residential Split---S ystem Lon gline

Application Guideline.

{ Required for Low---Ambient Controller (full modulation feature) MotorMasterr Control.

Accessory Description and Usage (Listed Alphabetically)

1. Ball--Bearing Fan Motor

A fan motor with ball bearings which permits speed reduction

while maintaining bearing lubrication.

Usage Guideline:

Required on all units when MotorMasterr —

2. Compressor Start Assist -- Capacitor and Relay

Start capacitor and relay gives a ”hard” boost to compressor

motor a t each start up.

Usage Guideline:

Required for reciprocating compressors in the

following applications:

Long line

Low a mbient cooling

Hard shut off expansion valve on indoor coil

Liquid line solenoid on indoor coil

Required for single--phase scroll compressors in the

following applications:

Long line

Low a mbient cooling

Suggested for all compressors in areas with a history of

low voltage problems.

3. Compressor Start Assist — PTC Type

Solid state electrical device which gives a ”soft” boost to the

compressor at each start--up.

Usage Guideline:

Suggested in installations with marginal power supply.

4. Crankcase Heater

An electric resistance heater which mounts to the base of the

compressor to keep the lubricant warm during off cycles.

Improves compressor lubrication on restart and minimizes the

chance of liquid slugging.

Usage Guideline:

Required in low ambient cooling applications.

Required in long line applications.

Suggested in all commercial applications.

5. Cycle Protector

The cycle protector is designed to prevent compressor short

cycling. This control provides an approximate 5--minute delay

after power to the compressor has been interrupted for any

reason, including power outage, protector control trip, thermostat

jiggling, or normal cycling.

6. Evaporator Fr eeze Thermostat

An SPST temperature--actuated switch that stops unit operation

when evaporator reaches freeze--up conditions.

Usage Guideline:

Required when low ambient kit has been added.

7. Low --Ambient Pressure Switch Kit

A long life pressure switch which is mounted to outdoor unit

service valve. It is designed to cycle the outdoor fan motor in

order to maintain head pressure within normal operating limits

(approximately 100 psig/689.5 KpA to 225 psig/1551.3 KpA.

The control will maintain working head pressure at low--ambient

temperatures down to 0_F ( --17.8_C) when properly installed.

Usage Guideline:

A Low --Ambient Pressure Switch or MotorMasterr

Low--Ambient Controller must be used when cooling operation is

used at outdoor temperatures below 55_F (12.8_C).

8. MotorMasterr Low--Ambient Controller

A fan--speed control device activated by a temperature sensor,

designed to control condenser fan motor speed in response to the

saturated, condensing temperature during operation in cooling

mode only. For outdoor temperatures down to -- 20_F (--28.9_C),

it maintains condensing temperature at 100_F ±10_F (37.8_C ±

6.5_C).

Usage Guideline:

A MotorMasterr Low Ambient Controller or

Low--Ambient Pressure Switch must be used when

cooling operation is used at outdoor temperatures

below 55_F (12.8_C).

Suggested for all commercial applications.

9. Outdoor Air Temperature Sensor

Designed for use with Bryant Thermostats listed in this

publ

i

cation. This device enables the thermostat to display the

outdoor temperature. This device also

is required to enable special thermostat features such as auxiliary

heat lock out.

Usage Guideline:

Suggested for all Bryant thermostats listed in this

publication.

124A