4. ASSEMBLY

4-11. Needle bar mechanism

Oil supp

ly hole

3392Q

Align th

e set screw with

the screw stop.

KE-430B, 430C series

82

Press the thread

take-up support shaft

gently while tightening

the set screw.

3393Q

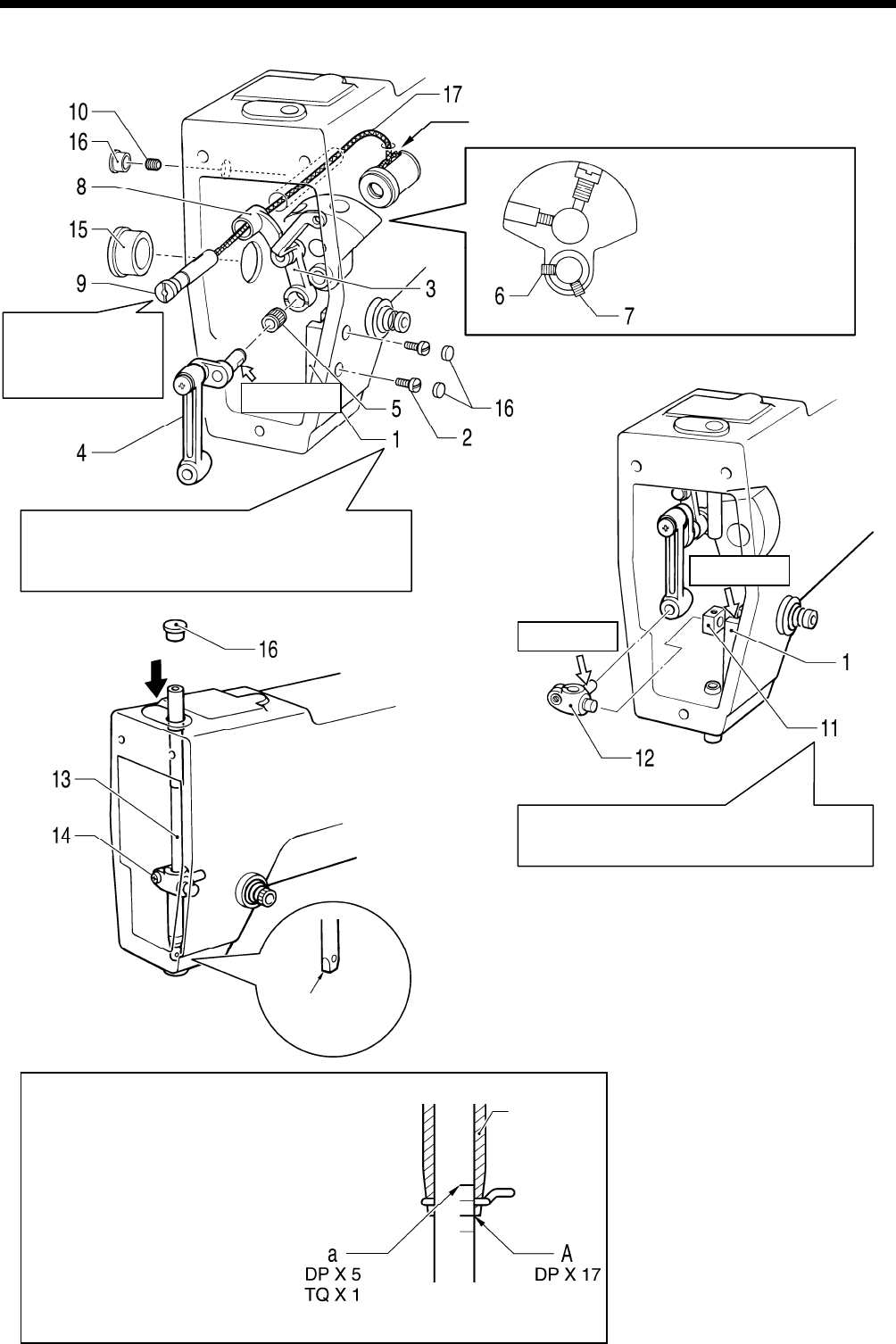

Apply grease.

After securing the needle bar, position the

ne

edle bar guide so that the machine pulley

turns smoothly, and then tighten the screws.

Apply grease.

Apply grease.

Fit the chamfering side of the slide block

into th

e groove on the needle bar guide.

1. Needle bar guide

2. Scre

ws

[2 pcs: Temporarily tighten]

3. Thread take-up lever

4. Needle bar connecting rod

Cut section

5. Ne

edle bearing

6. Set screw

3394Q

7. Set

screw

A

lign the needle bar so that

reference line A (the second

lowest reference line on the

needle bar) or reference line a

(top reference line) is aligned

with the lower edge of the

needle bar bush when the

machine pulley is turned to raise

the needle bar from its lowest

position, and then set the cut

section so that it is facing

forward and tighten the screw.

8. Th

read take-up support

Needle bar

9.

Thread take-up support shaft

bush

10. Set

screw

11. Slide block

12. Needle bar clamp

13. Needle bar [Insert from above]

14. Screw

15. Oil cap

16. Rubber caps [4 pcs]

17. Wick [Insert into oil supply

hole]

3395Q