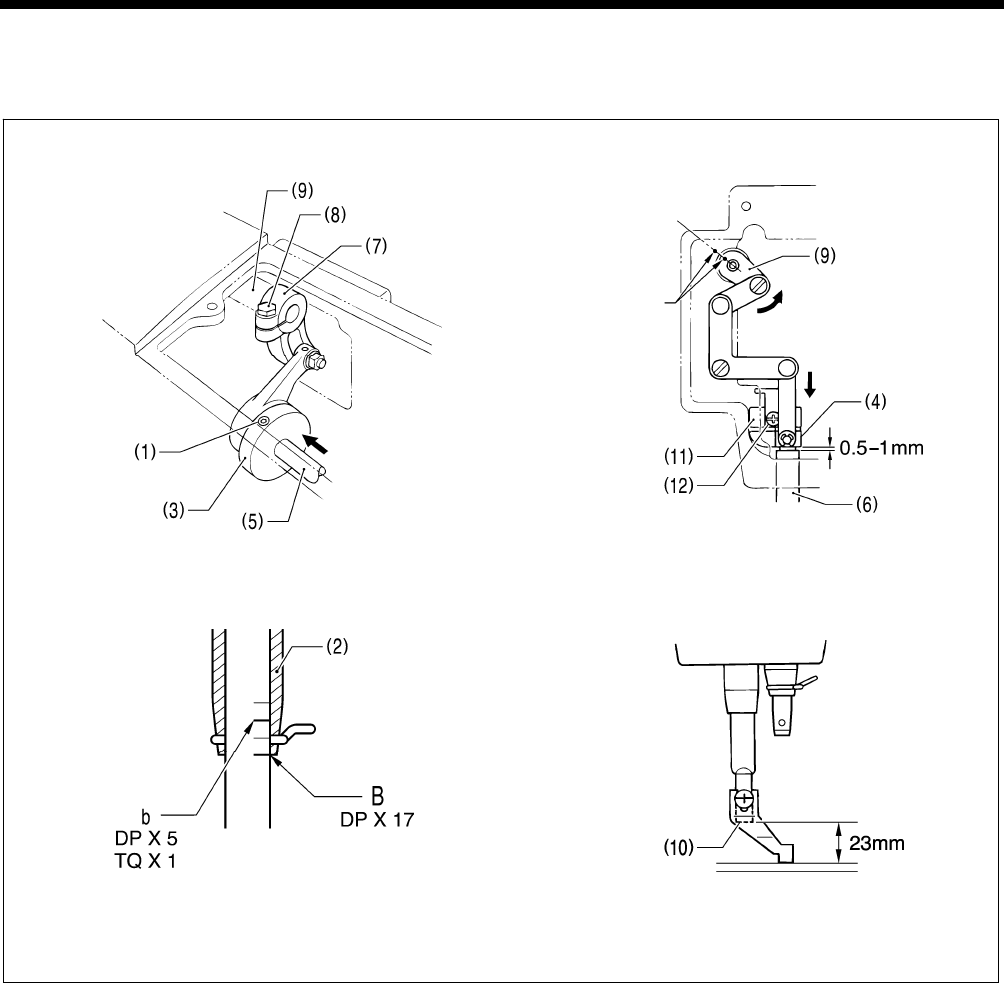

4. ASSEMBLY

4-10-1. Adjusting the lowest point of the presser foot

Carry out the steps in “4-11. Needle bar mechanism” before making this adjustment.

KE-430B, 430C series

81

3506Q 3507Q

Index marks

3508

Q 3509Q

1.

Loosen the set screw (1).

2. Turn the machine pulley to raise the needle bar from its lowest position until reference line B (the lowest

reference line on the needle bar) or reference line b (second reference line from the top) is aligned with the

lower edge of the needle bar bush (2).

3. Turn the stepping work clamp cam (3) without turning the machine pulley to set the presser bar lifter (4) to its

lowest position, and then secure the stepping work clamp cam (3) to the upper shaft (5) with the set screw (1).

* At this time, push the stepping work clamp cam (3) in the direction of the arrow so that there is no play

between it and the upper shaft (5).

4. With the presser bar lifter (4) at its lowest point, loosen the bolt (8) of stepping work clamp arm R (7) and

adjust so that the gap between the presser bar lifter (4) and the presser bar bush (6) is 0.5–1.0 mm. (A guide

to this is that the index mark on stepping work clamp arm F (9) should be about aligned with the index mark

on the arm.)

* Check that there is no forward or backward play in stepping work clamp arm F (9) at this time.

5. With the presser bar (10) at its lowest position, secure the presser bar clamp (11) with the screw (12) so that

the distance from the bottom edge of the presser bar and the top of the needle plate is 23 mm.