8. ELECTRIC MECHANISM

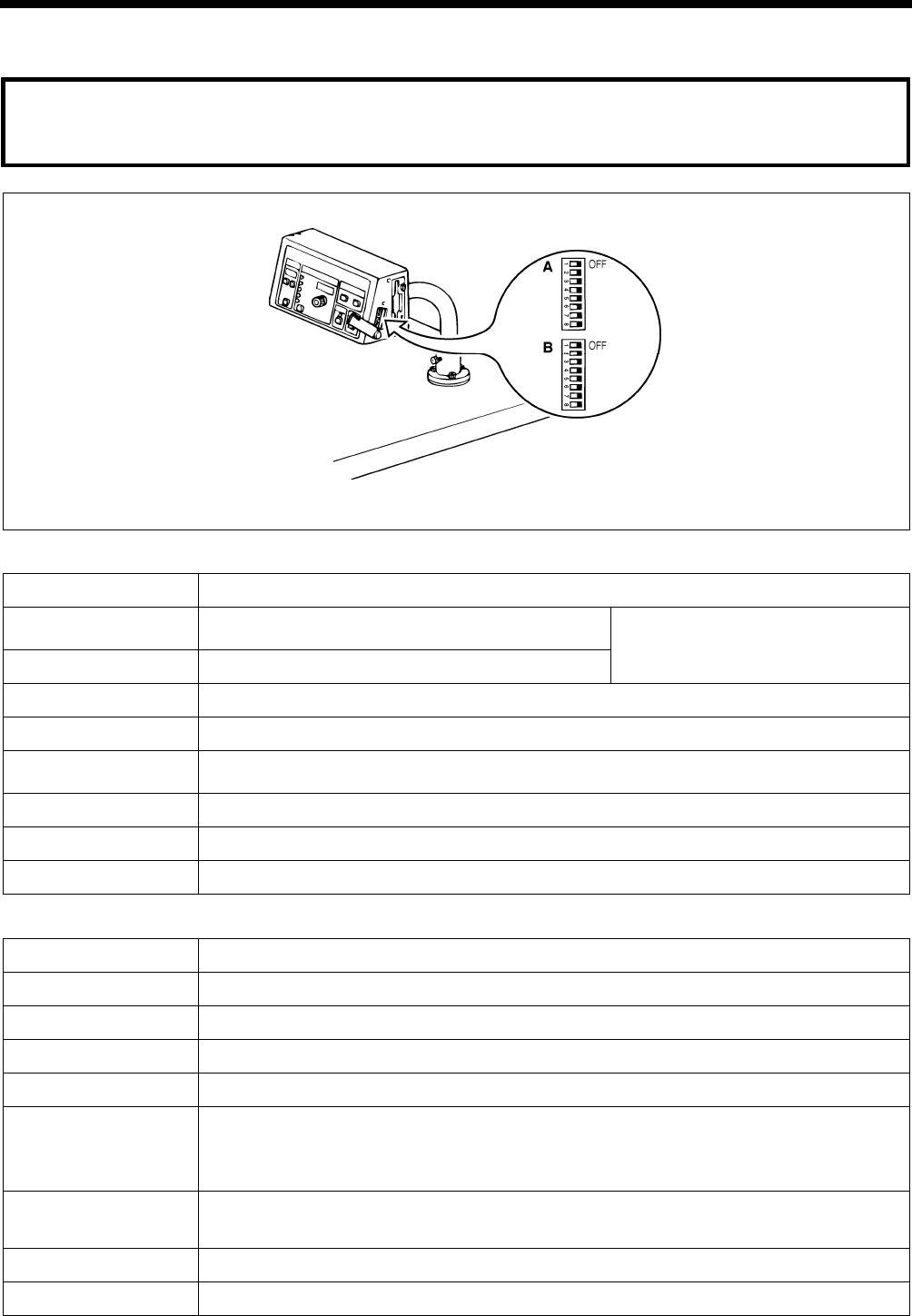

8-5-2. Operation panel DIP switches (KE-436B, 436C)

Note:

Always turn off the power before setting the DIP switches.

KE-430B, 430C series

148

1086Q

A

ll DIP switches are set to OFF at the time o

f

shipment.

DIP switch A

Switch Motion when set to ON

DIPA-1

Work clamp does not automatically lift after

sewing is completed.

DIPA-2 Pedal mode is switched.

See “8-8. Setting the work

clamp mode”

DIPA-3 -

DIPA-4 -

DIPA-5

After sewing is completed, work clamp does not automatically rise. (only in split

mode)

DIPA-6 Clamping force output is produced. (Inner clamping device available as an option)

DIPA-7 -

DIPA-8 Thread breakage detector device is activated (available as an option).

DIP switch B

Switch Motion when set to ON

DIPB-1 Single split mode activated

DIPB-2 -

DIPB-3 Thread is not trimmed after an emergency stop.

DIPB-4 Needle cooler output is produced. (Needle cooler available as an option)

DIPB-5

When a rotating-type thread breakage detector device is used, detection precision

is increased from 8 to 14.

When a fiber-type thread breakage detector device is used, detection precision is

increased from 5 to 10.

DIPB-6

Fiber-type thread breakage detector device is ON, and DIP switch A-8 is ON

(available as an option).

DIPB-7 -

DIPB-8 -