5. ADJUSTMENT

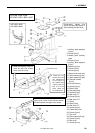

5-3. Adjusting the driver needle guard

* The KE-484C does not have a driver needle guard.

Ti

p

Needle center line

2556Q 0135Q

2555Q

Tu

rn the machine pulley to align the tip of the rotary hook with the needle center line. Then loosen the set screw

(2) and turn the eccentric shaft (3) to adjust so that the driver needle guard (1) contacts the needle.

If the needle contact pressure is too great, skipped stitches may occur. On the other hand, if the driver needle

guard (1) is not touching the needle, the tip of the inner rotary hook will obstruct the needle, resulting in an

excessively high amount of friction.

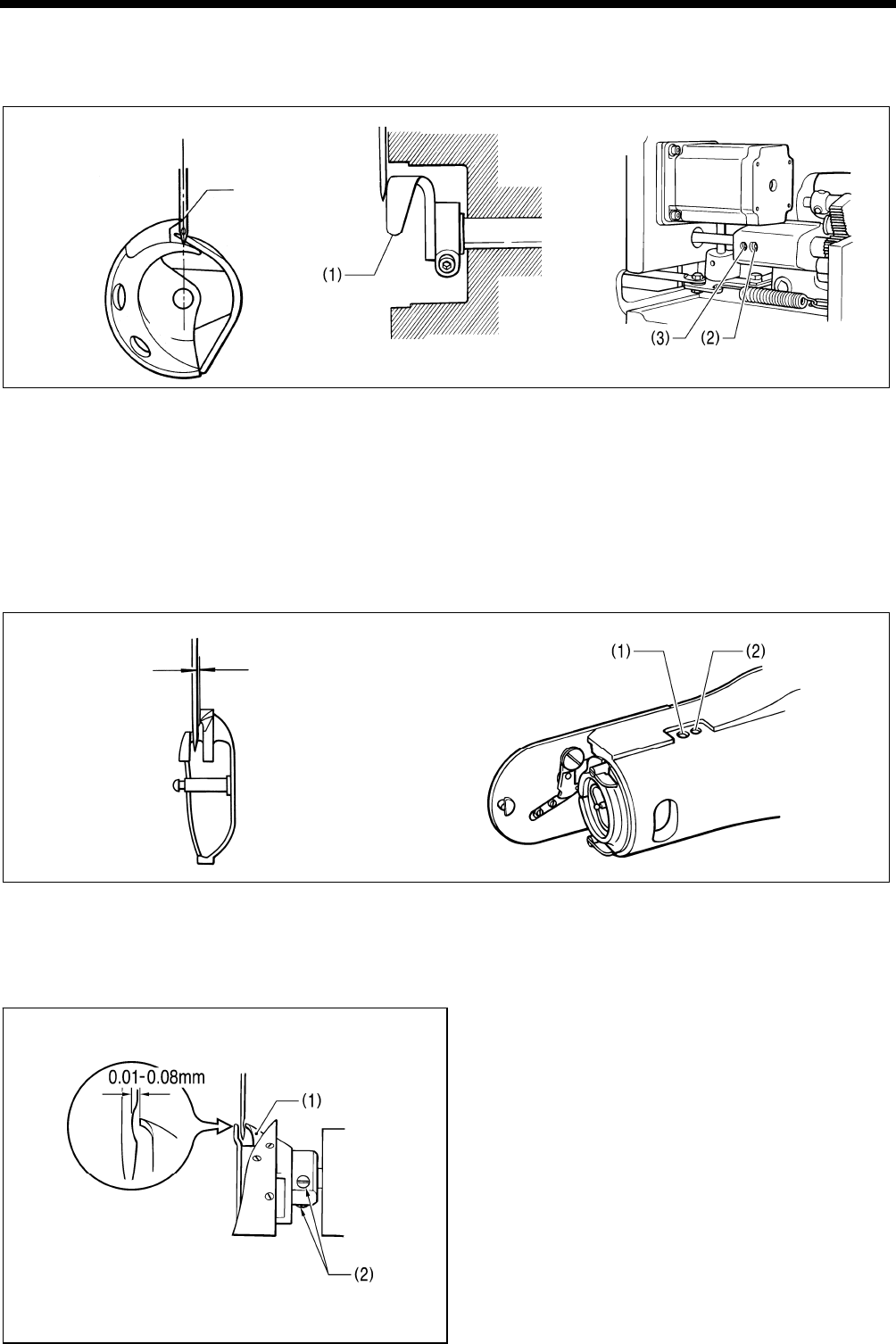

5-4. Adjusting the needle clearance

<KE-430B series, KE-430C series, BE-438B, 438C>

0.01 - 0.08 mm

2557Q

0138Q

Tu

rn the machine pulley to align the tip of the rotary hook with the needle center line. Then loosen the set screw

(1) and turn the eccentric shaft (2) to adjust so that the clearance between the needle and the rotary hook is 0.01

- 0.08 mm.

<KE-484C>

3201Q

Tu

rn the machine pulley to align the tip of the rotary

hook (1) with the needle center line. Then loosen

the set screw (2) to adjust so that the clearance

between the needle and the rotary hook (1) is 0.01 -

0.08 mm.

KE-430B, 430C series

101