8. ELECTRIC MECHANISM

KE-430B, 430C series

151

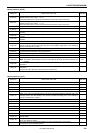

<Memory switches 00 - 0F>

Initial value

Switch Motion when set to ON

Solenoid

Pneumatic

memo-00

At the end of sewing, the feed plate will be returned to the sewing start point via

mechanical home position.

-- --

memo-01

Work clamp (button clamp) will move to the sewing start point, and then will be

lifted.

(For models with solenoid specifications other than the KE-434*, the work

clamp rises at the final stitch to enable quick taking out of the workpieces.)

*1 ON

memo-02

Feed will move automatically to the next starting point at the same time as a

user program is switched.

(Normally it moves to the starting point after sewing starts.)

-- --

memo-03

When sewing using programs, the programs which have been set will be sewn

in numerical order. (Cycle sewing mode is set.)

-- --

memo-04

The sewing speed will be fixed at the minimum speed for the maximum pitch of

the sewing data. (Set this to ON if you are concerned that variations in pitch

may cause changes in the sewing speed.)

-- --

memo-05

Increases the presser solenoid lifting force

(Set to ON when using the optional spring for extra-heavy material)

*2 --

memo-06 Enlargement and reduction ratio settings for X and Y become the same. -- --

memo-07 The inner clamping device can be used with pneumatic specifications. -- *3

memo-08 Test feeding is carried out stitch by stitch when the foot switch is depressed. *4 --

memo-09

The sewing start point becomes the reference point for enlargements and

reductions. (The reference point for enlargements and reductions is normally

the center of the sewing frame.)

-- --

memo-0A Work clamp does not close. (KE-432*) -- --

memo-0b Work clamp closes when the machine starts. (KE-432*) -- --

memo-0c

Needle stops in up position during emergency stop.

(EMERGENCY STOP switch is available as an option except for KE-434*, 435*,

484C)

-- --

memo-0d

The bar tacking stitches (with a pitch of less than 1 mm) are also enlarged and

reduced. (Normally stitches with a pitch of less than 1 mm are not enlarged or

reduced.)

-- --

memo-0E

Test feeding will be performed at the same speed as that for actual sewing.

(This is used for checking feeding operation.)

-- --

memo-0F

After sewing is finished, the work clamp automatically opens and closes once

(practice operation).

-- --

*1 ON for KE-434B, 434C, and “--” at other times

*2 ON for solenoid/heavy material specifications of KE-434B, 434C, and “--” at other times

*3 ON when the inner clamping device is being used, and “--” at other times

*4 ON for BE-438B, 438C, and “--” at other times

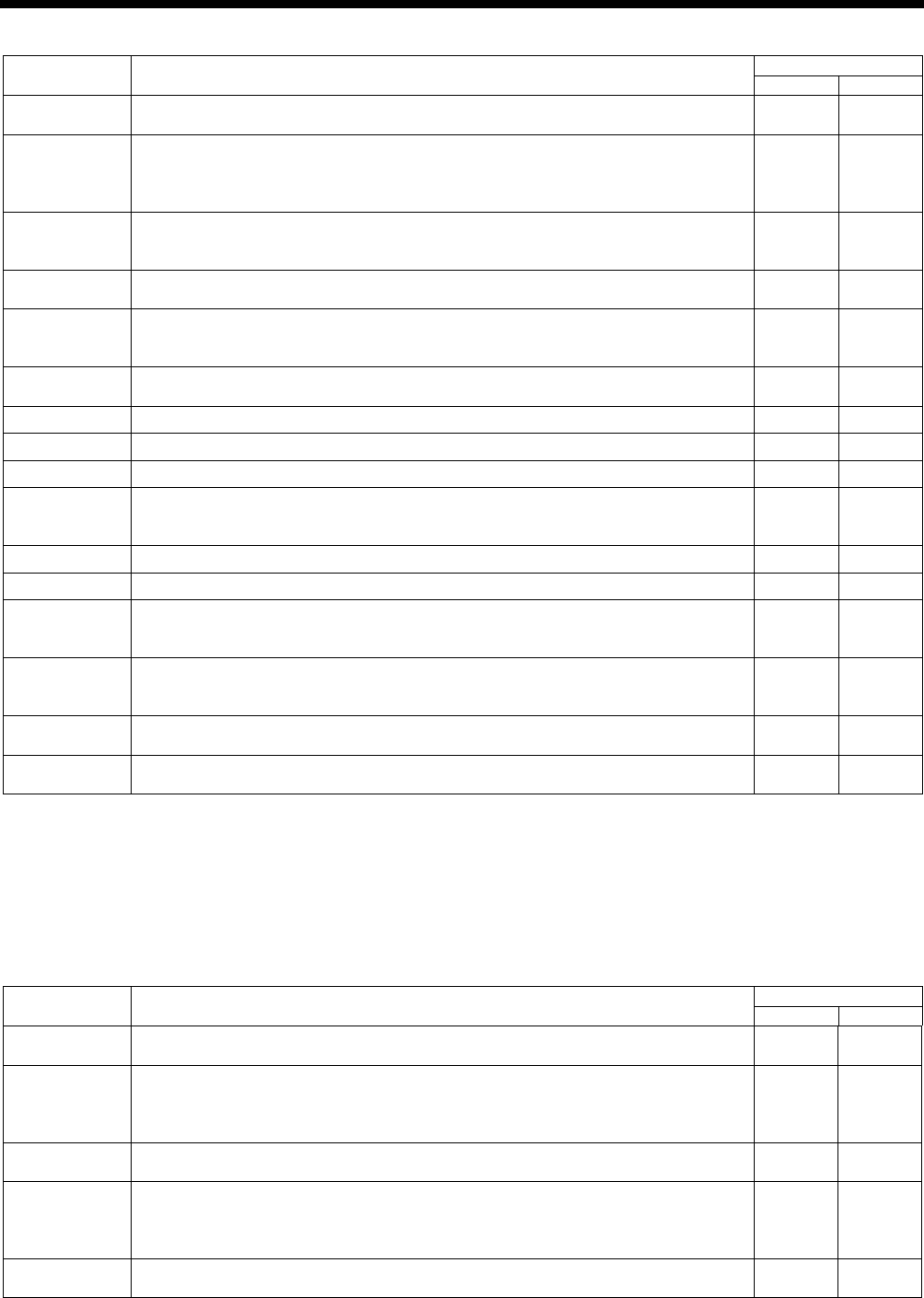

<Memory switches 10 - 1F>

Initial value

Switch Motion when set to ON

Solenoid

Pneumatic

memo-10

The optional emergency stop switch can be used. (KE-430*, 431*, 432*, 433B,

BE-438*)

-- --

memo-11

On when a two-stage tensioner is used. (Special order device that outputs from

option output No. 1)

(Normally the tension opens when output is OFF, and the tension closes when

option output No. 1 is ON)

-- --

memo-12

Pneumatic wiper can be used. (Special order device except for KE-484C that

outputs from option output No. 2)

-- *5

memo-13

The inner clamping device moves forward at the 1/4-way mark and returns at

the 3/4-way mark for the pattern being sewn.

(The device does not retract at this time, regardless of the setting for

memo-15.)

-- --

memo-14

Solenoid wiper can be used (available as an option except for KE-434*

pneumatic specification and KE-435*).

-- ON

*5 ON for KE-484C, and “--” at other times