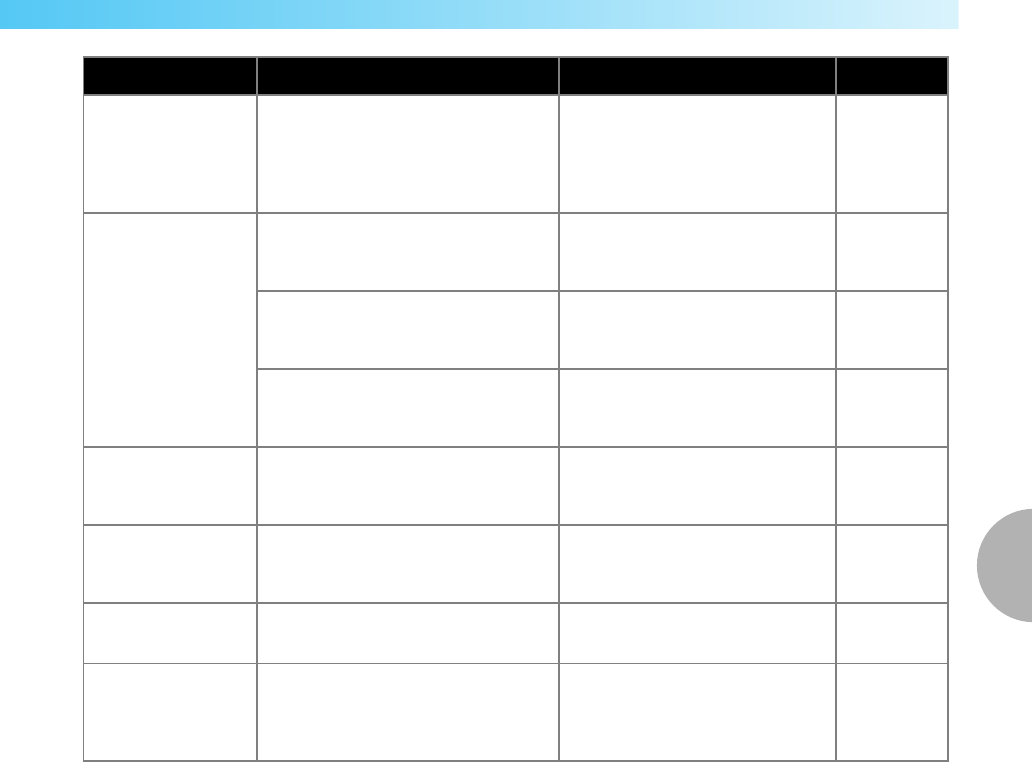

Troubleshooting 157

—

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

—

4

While winding the

bobbin, the bobbin

thread was wound

below the bobbin

winder seat.

You have not wound the bobbin

thread properly.

After removing the thread wound

below the bobbin winder seat,

wind the bobbin correctly.

page 151

Bobbin thread does

not wind neatly on

the bobbin.

The thread is not passed through the

bobbin-winding thread guide

correctly.

Correctly pass the thread through

the bobbin-winding thread guide.

page 24

Bobbin spins slowly.

Move the sewing speed controller

to the right (so that the speed will

be fast).

page 25

The thread that was pulled out was

not wound onto the bobbin

correctly.

Wind the thread that was pulled

off round the bobbin five or six

times clockwise.

page 25

Fabric being sewn

with the machine

cannot be removed.

Thread is tangled below the needle

plate.

Lift up the fabric and cut the

threads below it, and clean the

race.

page 148

The fabric feeds in

the opposite

direction.

The feed mechanism is damaged.

Contact your dealer or the nearest

authorized service center.

–

The upper thread

has tightened up.

The bobbin thread is incorrectly

installed.

Correctly install the bobbin

thread.

page

26, 144

The thread is

tangled on the

wrong side of the

fabric.

You have not threaded the upper

thread properly.

Correct the upper threading.

page

28, 145

Symptom Probable Cause Remedy Reference