11

• Install the flexible, gaseous hose (supplied) between

the home generator Fuel Inlet port and rigid piping to

prevent thermal expansion or contraction from causing

excessive stress on the piping material.

NOTE: Where local conditions include earthquake, tornado,

unstable ground, or flood hazards, special consideration

shall be given to increase strength and flexibility of piping

supports and connections.

CAUTION

The supplied flexible gaseous pipe is not to be installed

underground or in contact with the ground.

The entire flexible gaseous pipe must be visible for

periodic inspection and must not be concealed within,

contact, or run through any wall, floor, or partition.

•

• Piping must be of the correct size to maintain the

required supply pressures and volume flow under

varying generator load conditions with all gas

appliances connected to the fuel system turned on and

operating.

• Use a pipe sealant or joint compound approved for

use with NG/LPG on all threaded fittings to reduce the

possibility of leakage.

• Installed piping must be properly purged and leak

tested, in accordance with applicable codes and

standards.

WARNING

Propane and Natural Gas are extremely

flammable and explosive.

Fire or explosion can cause severe burns or

death.

Before placing the home generator into service, the fuel

system lines must be properly purged and leak tested.

NO leakage is permitted.

•

•

Consider the following factors when planning to install the

fuel supply system:

• A minimum of one accessible, approved manual shutoff

valve shall be installed in the fuel supply line within

6 ft (1.8 m) of the home generator. A union or flanged

connection shall be provided downstream from this

valve to permit removal of controls.

• LP gas fuel supply pressure should be 7 to 11 inches

of water (in. W.C.) at full load with all gas appliances

turned on and operating.

• Natural gas fuel supply pressure at the generator’s fuel

inlet port should be between 7 to 11 inches of water

(in. W.C.) at full load with all gas appliances turned on

and operating.

The home generator unit has been factory set to run on

natural gas. The unit can be converted from natural gas to

LP gas or vice versa using two people and special tools. See

Fuel Conversion, later in this manual.

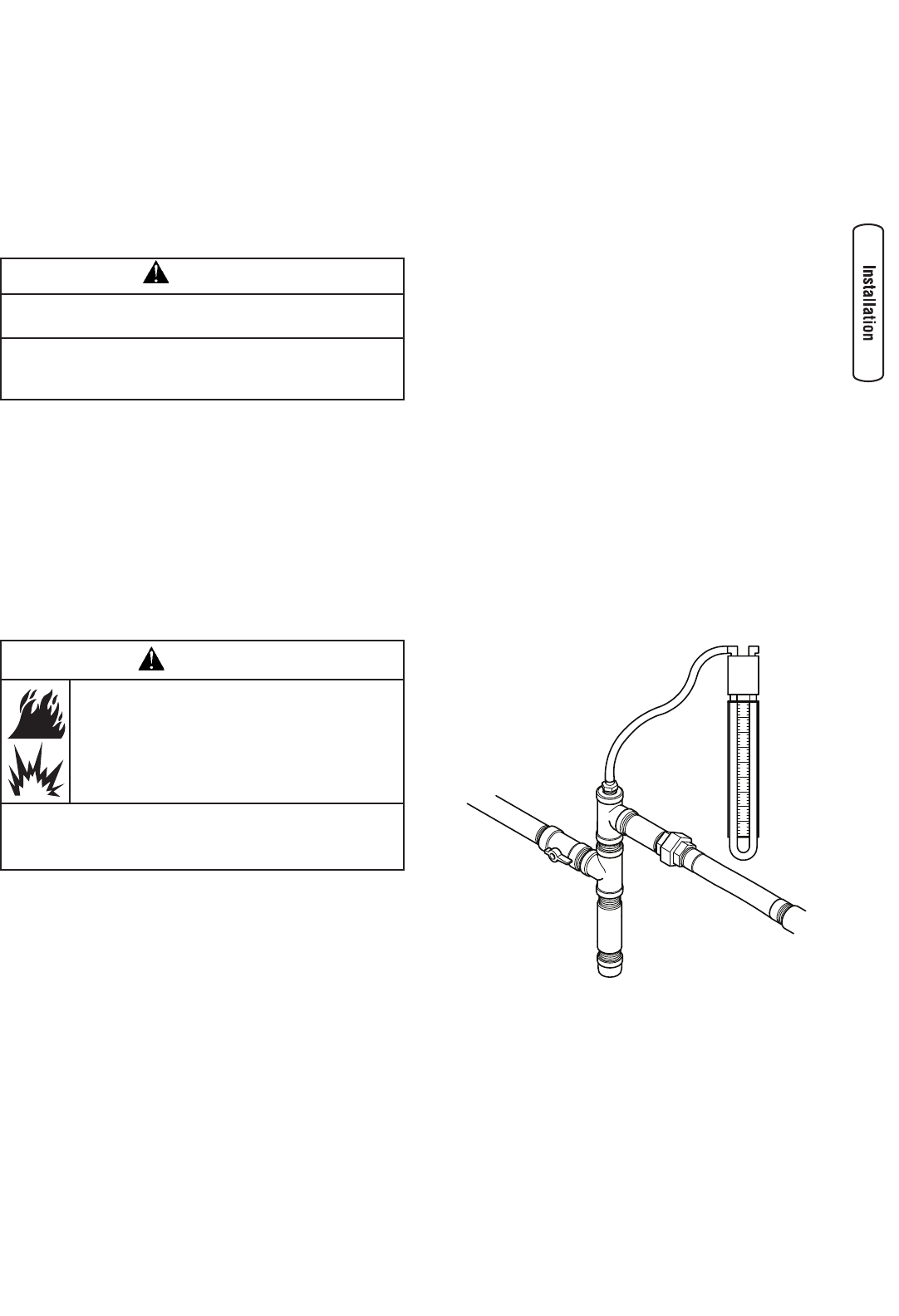

It is recommended that the fuel connection incorporate the

following components:

• A minimum 10 ft. (3 m) section of gas pipe between

the primary fuel regulator and the generator fuel inlet

connection (acts as accumulator for high block loads).

• A manual fuel shut-off valve located in the interior of

the building.

• A manual fuel shut-off valve located outside the

building, just before the generator unit.

• Where the formation of hydrates or ice is known to

occur, piping should be protected against freezing. The

termination of hard piping should include a sediment

trap where condensate is not likely to freeze.

• A manometer port should be provided.

The manometer port permits temporary installation of a

manometer to ensure that the engine receives the correct

fuel pressure to operate efficiently throughout its operating

range.

NOTE: A digital manometer, P/N 19495, is available at your

Briggs & Stratton service center.