Applications Manual Bosch Greenstar | 57

Bosch Thermotechnology Corp.

Data subject to change

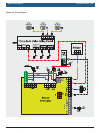

2.12 System 12: Greenstar Heating Boiler with

zone valves and room thermostats

Summary:

Single boiler with primary/secondary piping confi gura-

tion supplying three heating zones controlled by 3rd party

room thermostats with zone valves. Outdoor reset with

FW200 controller mounted on the boiler.

The zone circulator runs only when a heat demand is com-

municated by the room thermostats and shut off when the

heat demand goes away.

Primary/secondary piping isolates the system fl ow from

the boiler fl ow and prevents the system from infl uencing

boiler performance.

This setup allows the use of a low energy ECM pump (e.g.

Grundfos Alpha) that adjusts the fl ow rate based on back

pressure depending on the number of zones calling.

This system works particularly well for installations with

other heat sources, e.g. wood stoves or signifi cant solar

gain. Compared to systems with the FW200 installed in the

room that will throttle down the boiler output when the

room reaches its set point, in this setup the thermostat

will shut the boiler off.

This system can also be used with a combi boiler (see

system 6) instead of the indirect fi red DHW tank.

In detail:

This system runs on pure outdoor reset without room

feedback on the heating curve. The FW200 installed in the

boiler adjusts the heating curve (boiler supply tempera-

ture) according to outdoor temperature.

The 3rd party room thermostats turn the boiler and the

zone pump on and off based on the conditions in the living

space.

FW200 provides warm weather shutdown.

For temperature sensitive radiant fl oor applications install

a thermostatic tempering valve for overheat protection.

Required components:

Greenstar heating boiler.

FW200 controller in the boiler.

Primary/secondary piping and system pump.

Thermostatic mixing valve (optional - overheat

protection for temperature sensitive floors).

3rd party room thermostats with dry contact closure

in each zone.

Zone valve panel (e.g. TACO ZVC403 or similar).

Zone pump (ECM recommended).

Indirect fired DHW tank.

Tank loading pump of sufficient capacity.

Additional instructions:

See manufacturer’s installation and operating instructions.