F00633 Page 5

Centerline

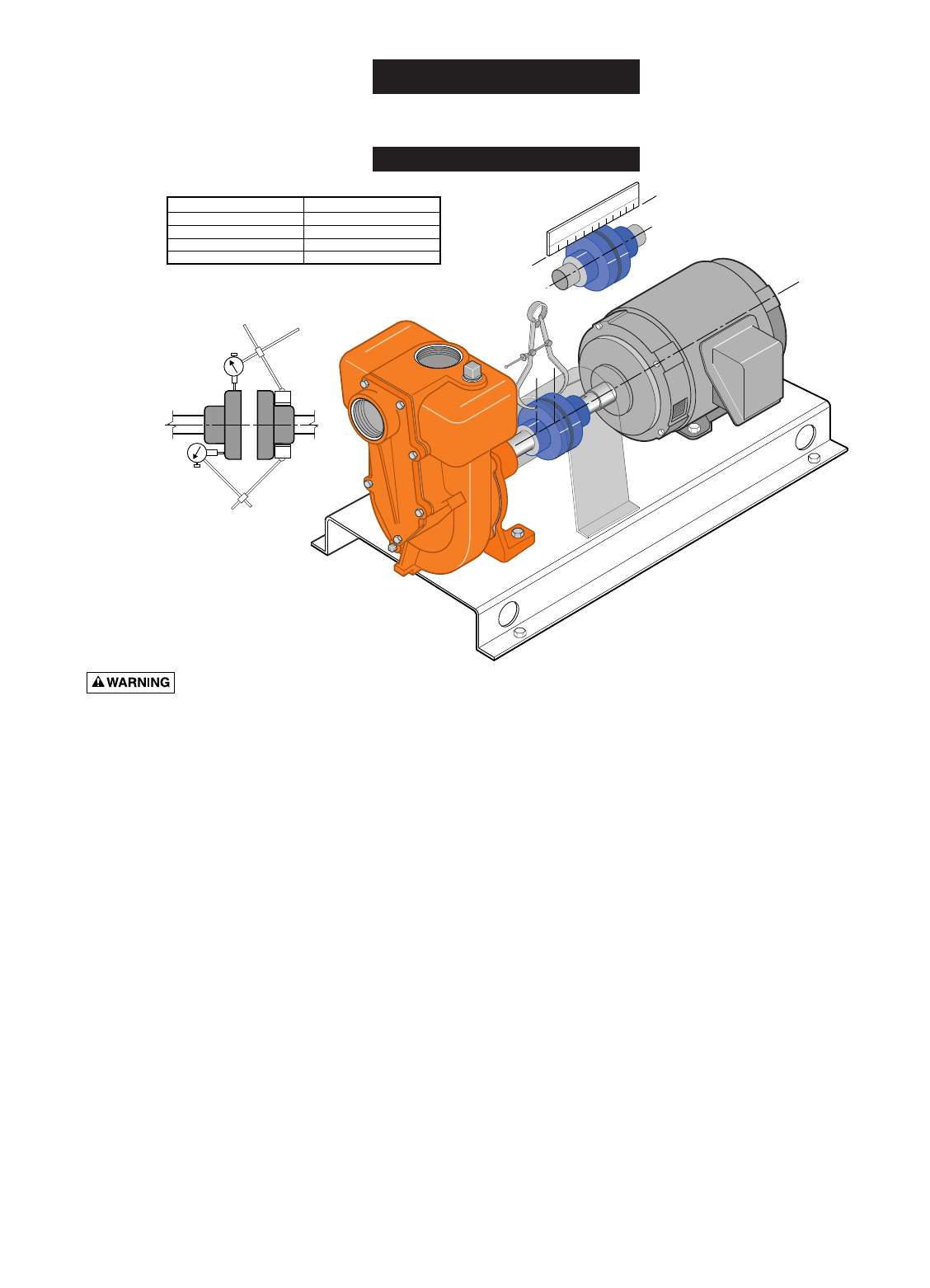

2112 1095

Caliper

Straight Edge

"B"

Parallel

"A"

Angular

Table I

Distance from Centerline Maximum Allowable T.I.R.

4.00 inches

3.00 inches

2.00 inches

1.00 inch 0.035 inches

0.070 inches

0.105 inches

0.140 inches

Rotating shaft can catch and trap

clothing or body. Coupling guard must

ALWAYS be in place when pump is running. Coupling

guard shown in phantom for pictorial clarity.

ALIGNMENT OF PUMP AND MOTOR SHAFT

•A flexible coupling (except for double universal joint

shaft) will not compensate for misalignment. After the

pump unit is fastened on the foundation, it is nec-

essary to see that the shafts of the pump and motor

are properly aligned.

• Each motor and pump foot should be shimmed to

avoid shifting or soft foot.

COURSE ALIGNMENT

• By moving the entire unit, bring suction and discharge

openings of the pump into alignment with the system

piping. Install piping at this time. Pipes should align

naturally with the pump (see Installation Section).

• Bring the pump and motor shaft into approximate

alignment by shifting or shimming the motor. Use a

straight edge to check alignment of the shafts.

• Use calipers, or a wedge thickness gauge to check

the distance between coupling halves. The distance

between halves should be equal at 90 degree

intervals around the coupling, and the shafts should

be concentric when checked with a straight edge.

FINE ALIGNMENT

• Angular and parallel misalignment of the coupling

may be corrected simultaneously. Maintain a sep-

aration between coupling halves, per manufacturer’s

specifications, to avoid preloading of pump and motor

bearings. Clamp dial indicators to the pump and

motor shaft as shown above.

• Start with angular alignment and finish check with

parallel alignment.

• Rotate both the shaft and coupling together by hand.

Note the total indicated runout shown on indicator “A”.

The maximum allowable angular misalignment is 1

degree. Limits of reading on indicator “A” at various

distances from shaft centerline are shown in Table I.

• Continue to rotate both shafts by hand and note the

runout shown on indicator “B”. The maximum allow-

able total indicated runout is .005 inches. Should

either angular or parallel misalignment exceed the

value shown, shift or shim the motor until mis-

alignment is within the allowable limits shown. Do not

move pump unless absolutely necessary. When

shimming, be sure that all feet on the pump and

motor are equally supported to avoid strains on the

castings when the hold down bolts are tightened.

Direct Coupling Drive

Installation

Shaft Alignment

Fine Alignment

Course Alignment